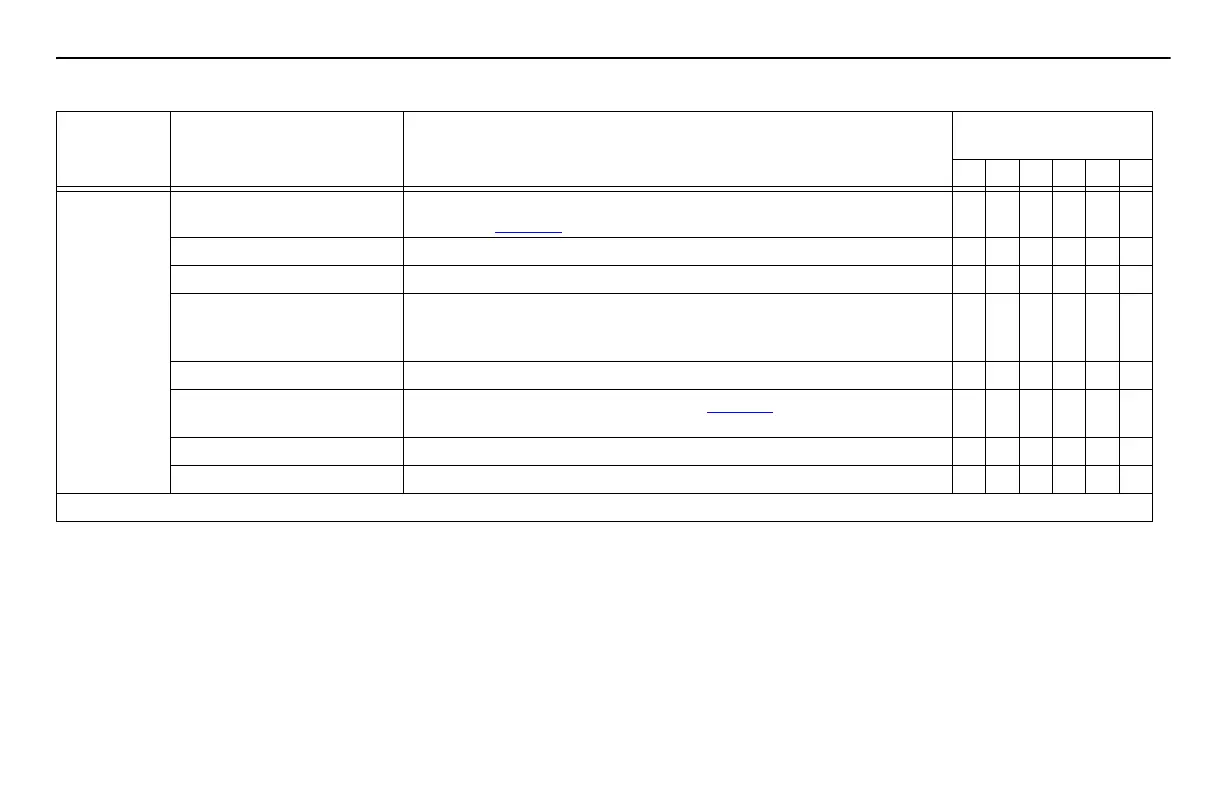

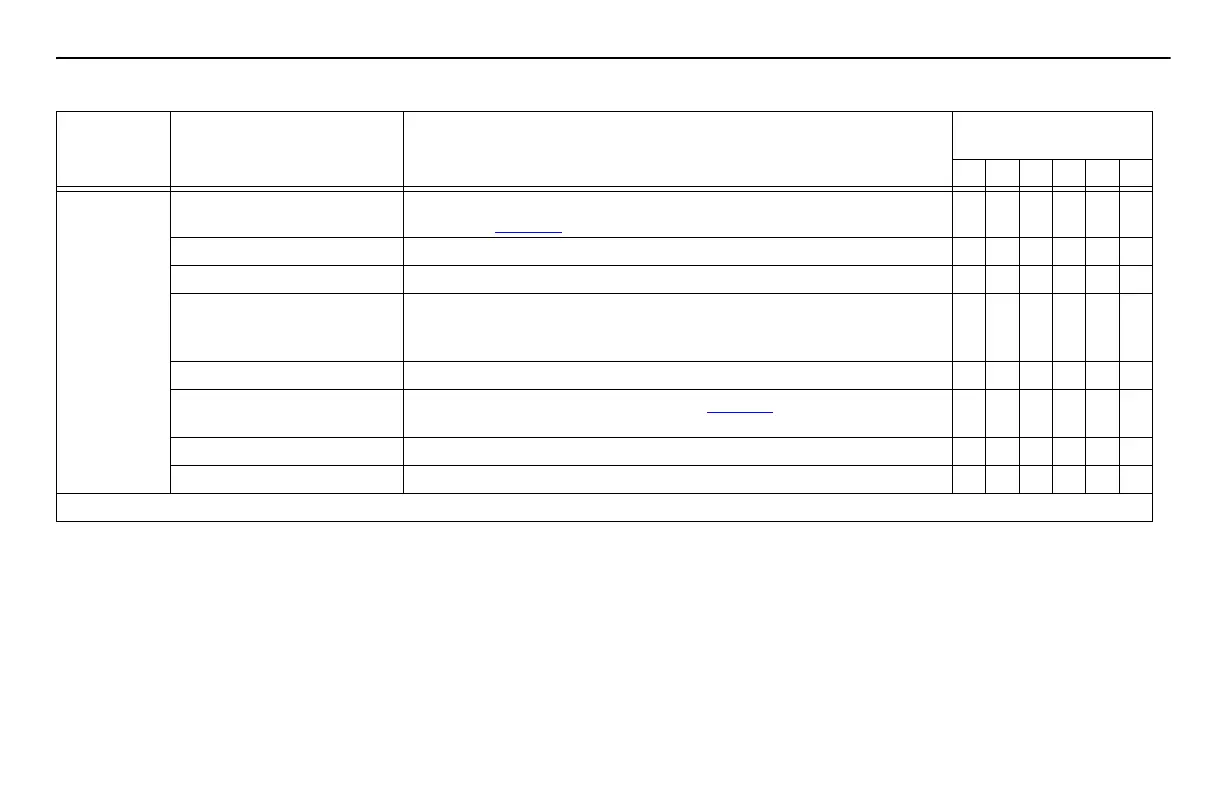

PREVENTIVE MAINTENANCE SCHEDULE PART 8: MAINTENANCE AND SERVICE

– 126 – Y53-6007 (R10/06)

Drum

Brakes

(All)

Slack adjusters Check the push rod travel and check the control arm for cracks. Adjust at

reline (see

page 152).

X

Slack adjusters Lubricate (NLGI #2 grease). X

Brake camshaft bearing Lubricate (NLGI #2 grease). X

Brake treadle valve Clean the area around the treadle, boot, and mounting plate. Check the

pivot and mounting plate for integrity. Check the plunger boot for cracks.

Lubricate roller pin, pivot pin, and plunger (NLGI #2 grease).

X

Brake treadle valve Rebuild through an authorized Peterbilt service facility. X

Brake air system Check air lines and fittings for leaks (see page 152). Adjust routing as

required to reduce chafing. Check tank mounting and condition.

X

Brake air system Clean or replace the inline filters. X

Brake lining Inspect; replace as required. X

Table 2 Preventative Maintenance Schedule (Continued)

SYSTEM COMPONENT MAINTENANCE TASK

Recommended

PM Interval

I ABCDE

Loading...

Loading...