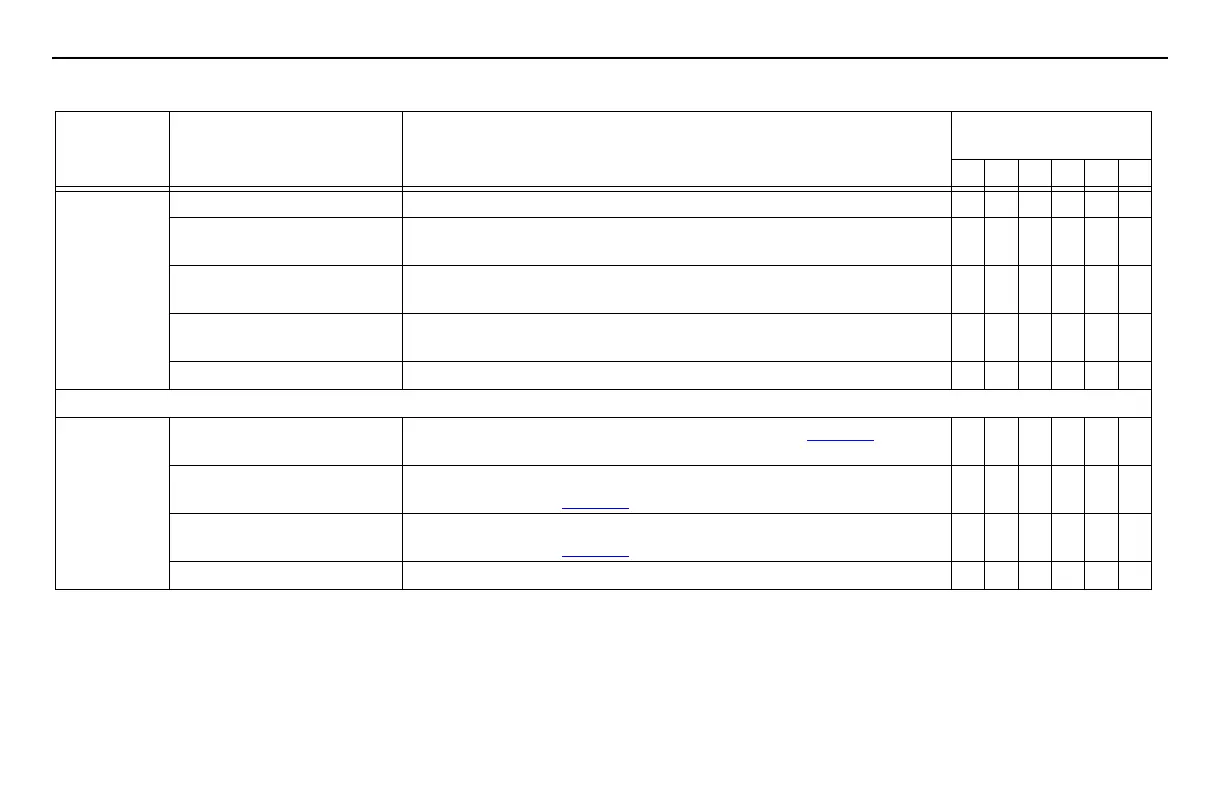

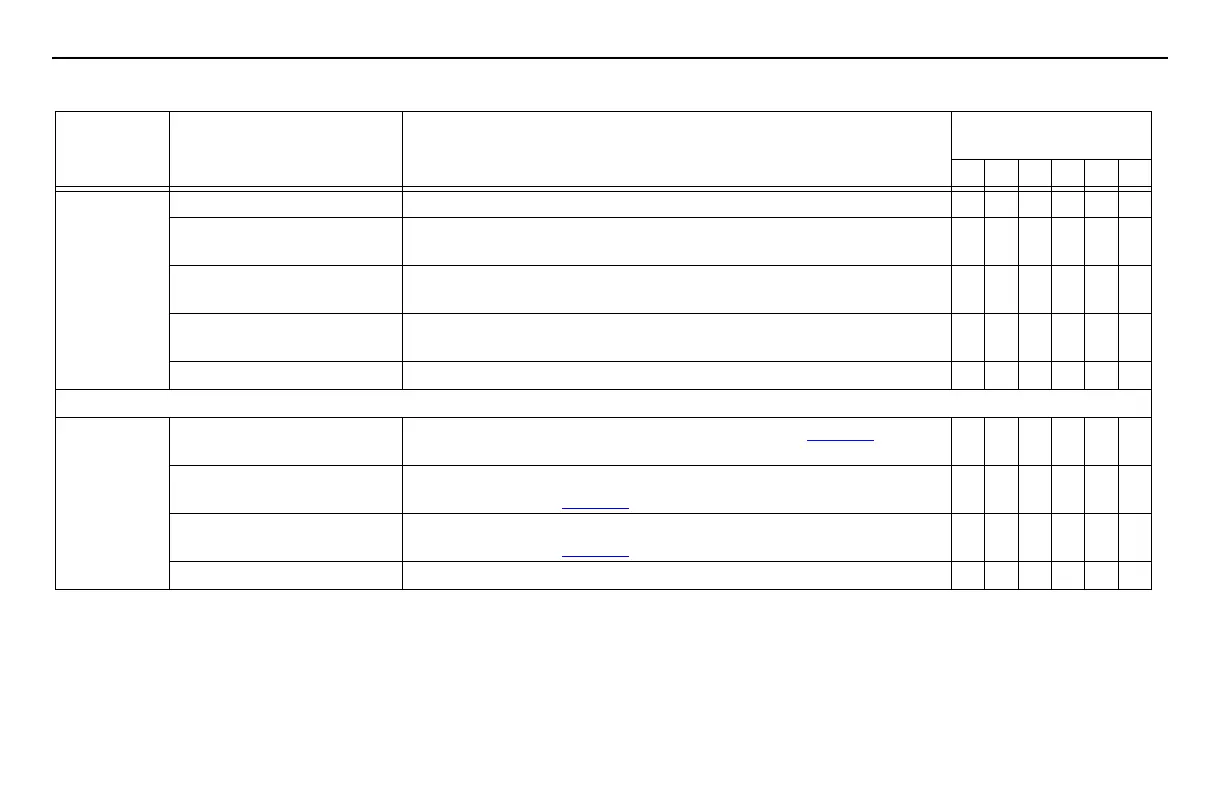

PART 8: MAINTENANCE AND SERVICE PREVENTIVE MAINTENANCE SCHEDULE

(R10/06) Y53-6007 – 127 –

Disc Brakes

(All)

Brake pads Inspect; replace as required. X

Brake disc/rotor Inspect for visible cracks, heat checking, galling, or scoring of surface.

Check thickness minimum of 1.46” (37 mm).

X

Caliper sliding function Ensure caliper slides freely with no obstructions or excessive play (see

manufacturer’s service literature for “Checking Running Clearance”).

X

Caliper function Inspect bearings, seals, tappet and boots of the guide pins for damage or

cracking.

X

Adjuster Check operation; inspect as per manufacturer’s service literature. X

Hub, Drum,

& Hubcap

Hubs (non-LMS)

Meritor Unitized Wheel End

Check the bearing endplay and adjust as required (see page 164).

X

Hubs (non-LMS) with outrun-

ner seals

Clean the components and check for excessive wear or damage. Change

the oil and seal (see

page 164).

X

Hubs (non-LMS) with stan-

dard seals

Clean the components and check for excessive wear or damage. Change

the oil and seal (see

page 164).

X

Hub seals (all) Check for leaks; replace as required. X

Table 2 Preventative Maintenance Schedule (Continued)

SYSTEM COMPONENT MAINTENANCE TASK

Recommended

PM Interval

I ABCDE

Loading...

Loading...