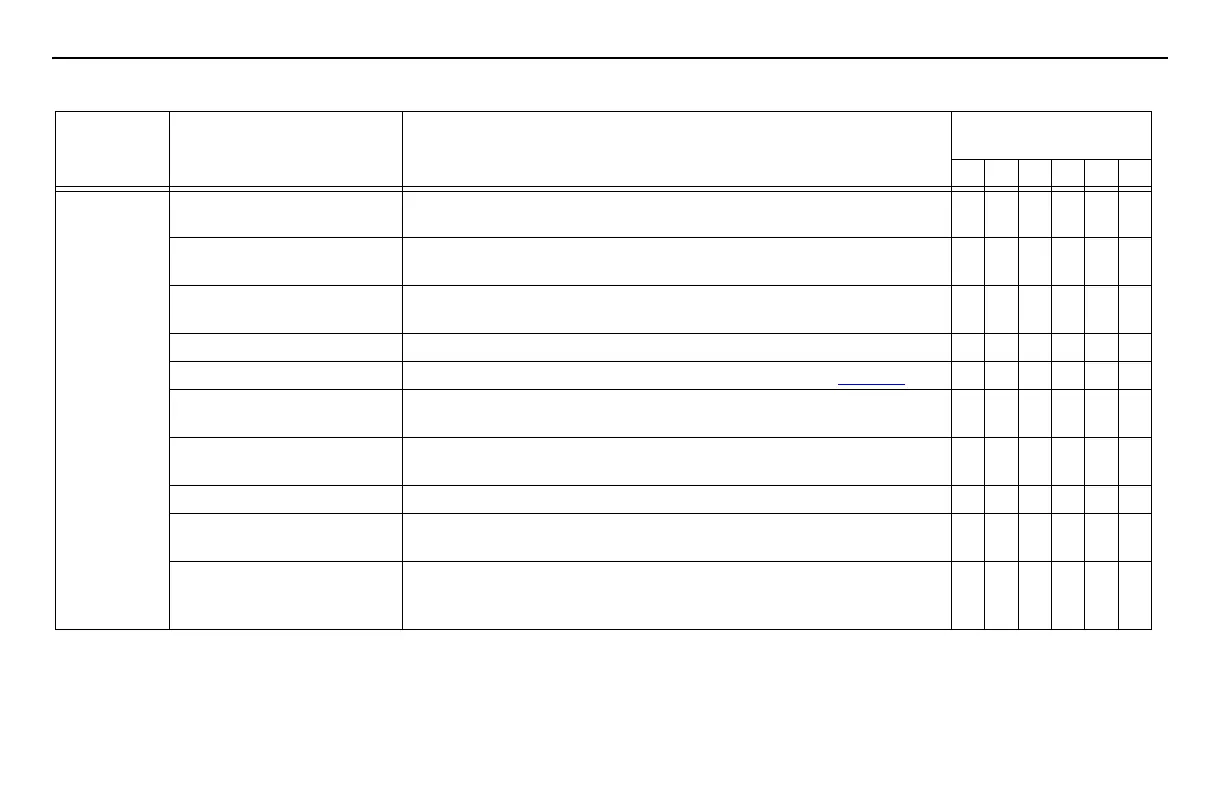

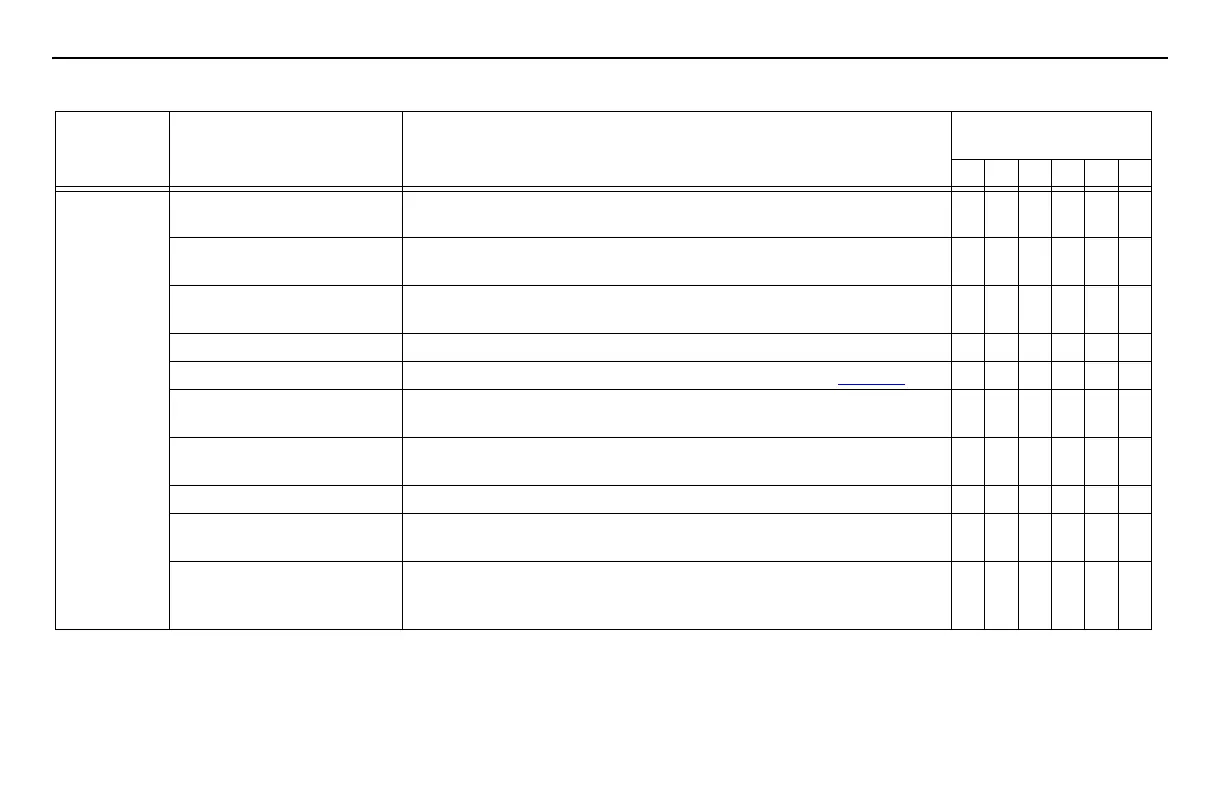

PART 8: MAINTENANCE AND SERVICE PREVENTIVE MAINTENANCE SCHEDULE

(R10/06) Y53-6007 – 133 –

Power

Steering

Steering gear Grease the trunnion bearing (EP NLGI #2 lithium-based, moly-filled, HD

grease).

X

Steering gear Grease the input shaft seal (EP NLGI #2 lithium-based, moly-filled, HD

grease).

X

Power assist cylinder Lubricate the ball joints. Inspect for leaking rod seals, damaged ball joint

boots, and damage to cylinder rod or barrel.

X

Hoses and tubes Check for leaks and chafing. X

Steering linkage Check all joints for excessive lash; replace as required (see page 183). X

Draglink tube clamp and ball

socket

Check the torque; tighten to specified torque value as required.

X X

Pitman arm clamp bolt and

nut

Check the torque; tighten to specified torque value as required.

X X

Steering intermediate shaft Check the torque on the pinch bolt and nut. X X

Steering intermediate shaft

U-joints (ON HIGHWAY)

Lubricate [EP NLGI #2 HD grease, +325° F to -10° F (+163° C to

-23° C) range].

X X

Steering intermediate shaft

U-joints (OFF HIGHWAY or

CITY DELIVERY)

Lubricate [EP NLGI #2 HD grease, +325° F to -10° F (+163° C to

-23° C) range]. X X

Table 2 Preventative Maintenance Schedule (Continued)

SYSTEM COMPONENT MAINTENANCE TASK

Recommended

PM Interval

I ABCDE

Loading...

Loading...