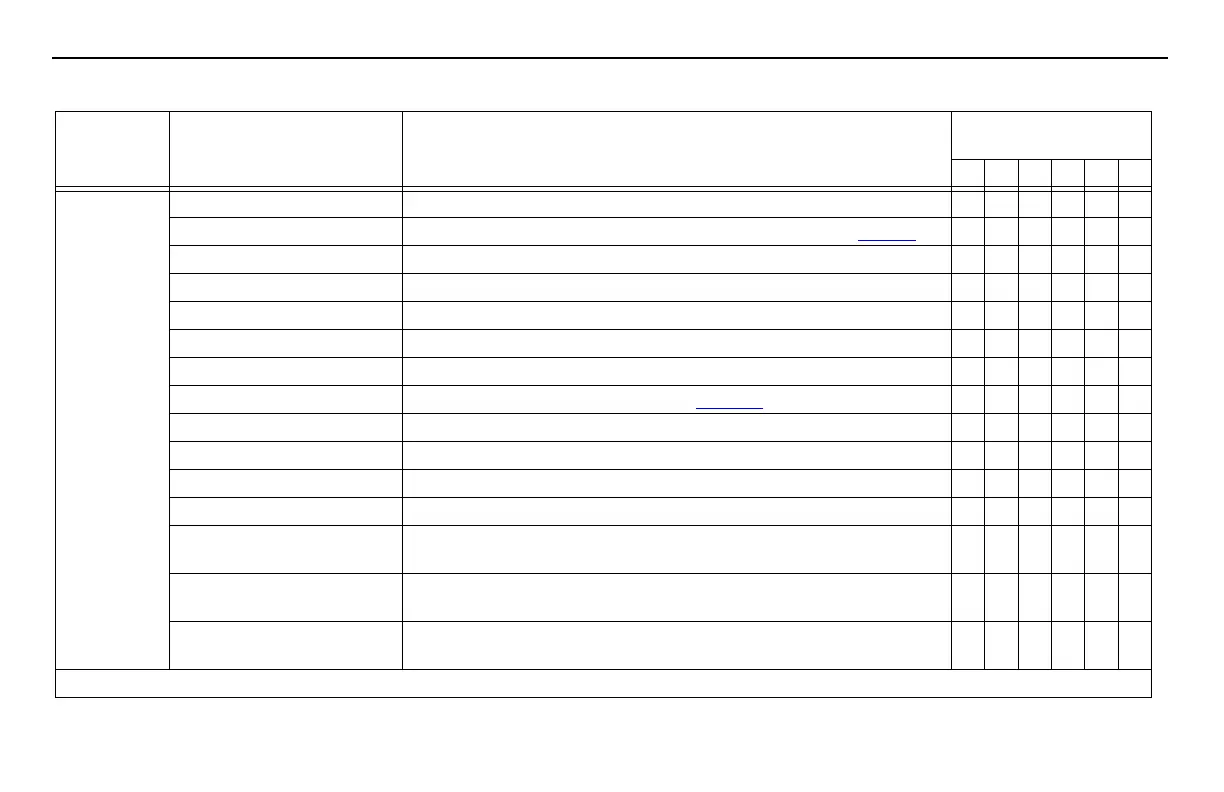

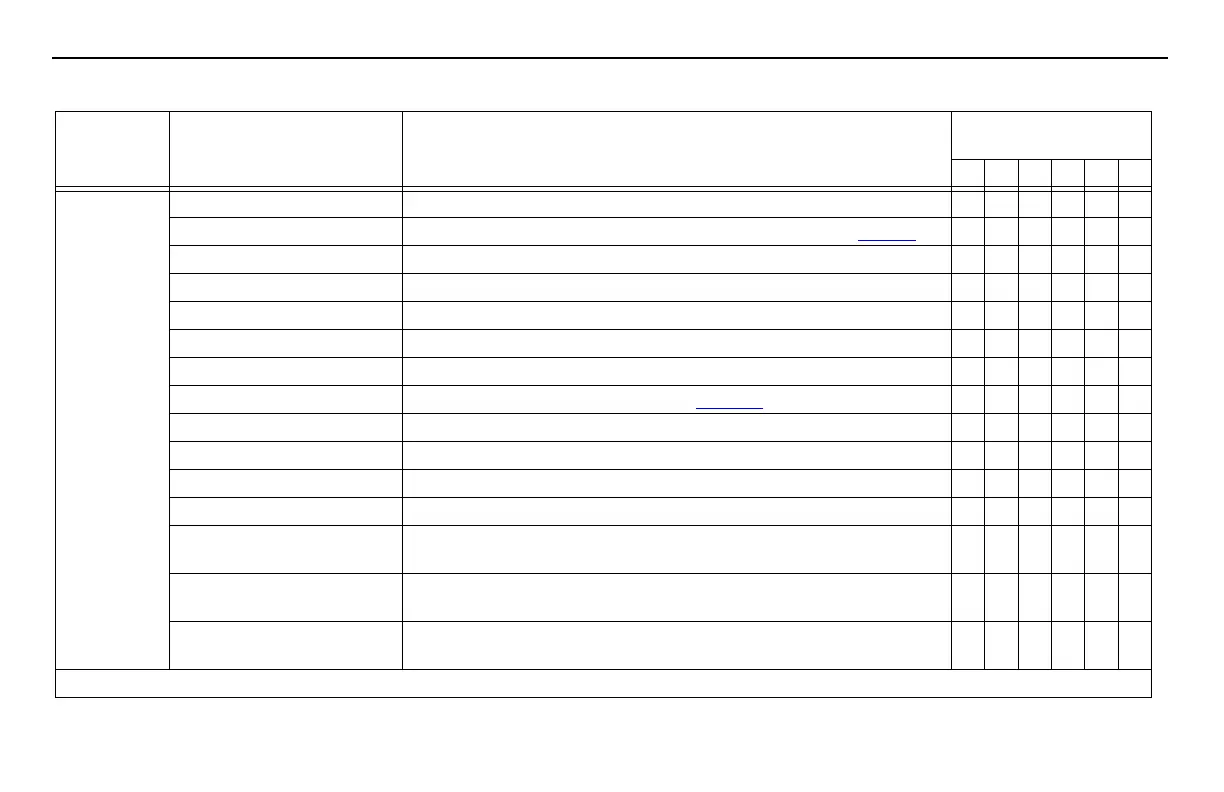

PART 8: MAINTENANCE AND SERVICE PREVENTIVE MAINTENANCE SCHEDULE

(R10/06) Y53-6007 – 137 –

Electrical &

lights

Headlamps Check the aim and adjust as required. X

Warning lights in light bar Check at the ignition start position to verify bulbs function (see page 47). X

Turn signal Visual check. X

Stop lights Visual check. X

Reverse lights Visual check. X

Alternator Check operation and output. X

Alternator Check tightness of the pulley nut. X

Alternator Check the tension of the drive belt (see page 187). X

Alternator Check tightness of the terminal hex nuts. X

Starter Check torque on hex nuts. X

ECM connector Check the tightness of the ECM connector. X

Wheel sensors Check for damaged sensors and connectors, and worn or frayed wires. X

Fuel tank sending unit Check the mounting screws and electrical connections for worn or dam-

aged wires and connectors.

X X

Power supply harnesses

(engine, transmission, etc.)

Check for worn or damaged insulation, corroded terminals, frayed wires,

and oil or fluid leaks on the connectors or wiring.

X

Power supply harnesses

(engine, transmission, etc.)

Wash to remove excess grease.

X

Table 2 Preventative Maintenance Schedule (Continued)

SYSTEM COMPONENT MAINTENANCE TASK

Recommended

PM Interval

I ABCDE

Loading...

Loading...