19

Correct

setting:

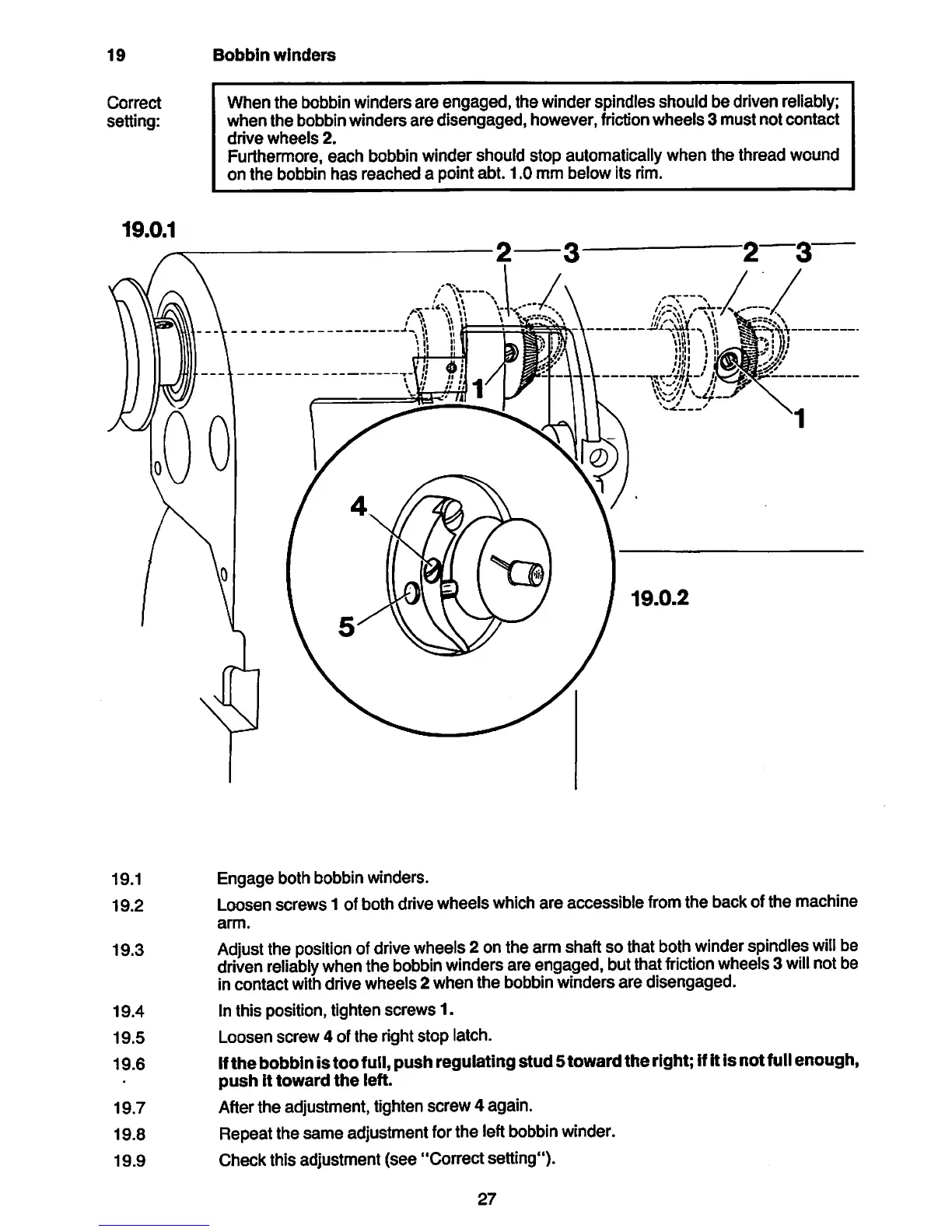

19.0.1

Bobbin

winders

When the bobbin winders are

engaged,

the winder spindlesshould be driven reliably;

when

the

bobbin

winders

are

disengaged,

however, friction

wheels

3

must

not

contact

drive

wheels

2.

Furthermore,

each

bobbin winder should

stop

automatically

when

the

thread

wound

on

the

bobbin

has

reached

a point abt. 1.0 mm below Its rim.

19.0.2

19.1 Engage both bobbin winders.

19.2 Loosen

screws

1 of both drive wheelswhich

are

accessible from the back of the machine

arm.

19.3

Adjust

the

position

of

drive

wheels

2onthearmshaftsothat

both

winder

spindles

will

be

driven

reliably

whenthe

bobbin

winders

areengaged,butthat

friction

wheels3

will

notbe

in

contact

with drive

wheels

2

when

the

bobbin winders

are

disengaged.

19.4

Inthis position, tighten

screws

1.

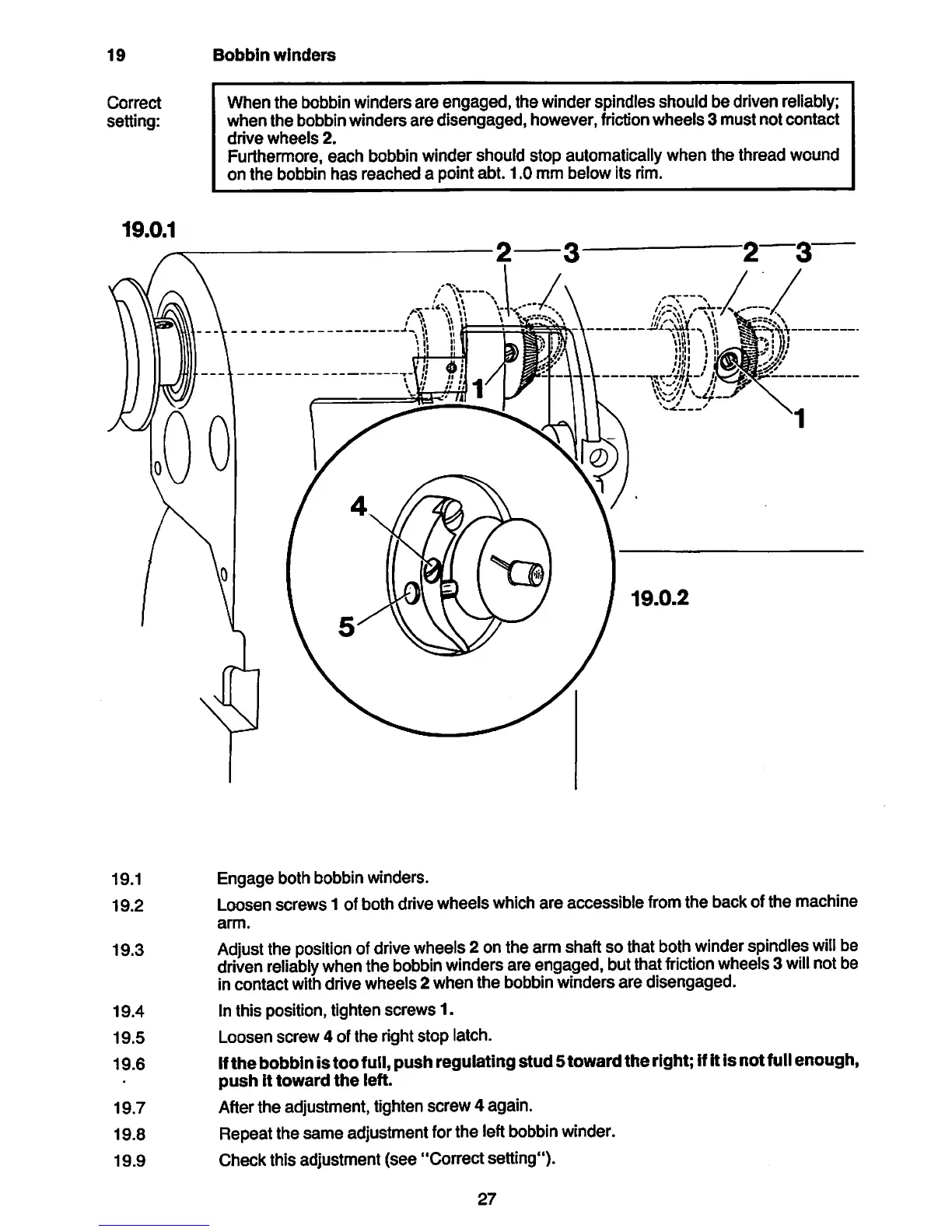

19.5

Loosen

screw

4 of

the

right

stop

latch.

19.6 If

the

bobbinis

too

full,

push

regulating

stud

5toward

the

right; ifitis not full

enough,

push

it

toward

the

left.

19.7 Afterthe adjustment, tightenscrew 4 again.

19.8 Repeat the same adjustment forthe leftbobbinwinder.

19.9 Check this adjustment (see "Correct setting").

27

Loading...

Loading...