P.O. Box 1306, Newport Beach, California 92663 • Phone: 714-751-0488 • Fax: 714-957-1621 • E-Mail: techservice@newmarpower.com

www.newmarpower.com

10

Therefore, the Phase Three charger is designed to utilize an

optional remote sensor (available from NEWMAR; model TCS-

12/24) which provides automatic temperature compensation. The

remote sensor will signal the charger to fine tune its output voltage

so that it is properly matched to the temperature of the battery/

battery environment. The adjustment rate is approximately -5 mV

per cell per °C. (Note: The temperature compensation option is

strongly recommended for sealed, valve-regulated, AGM or gel-

cell batteries.)

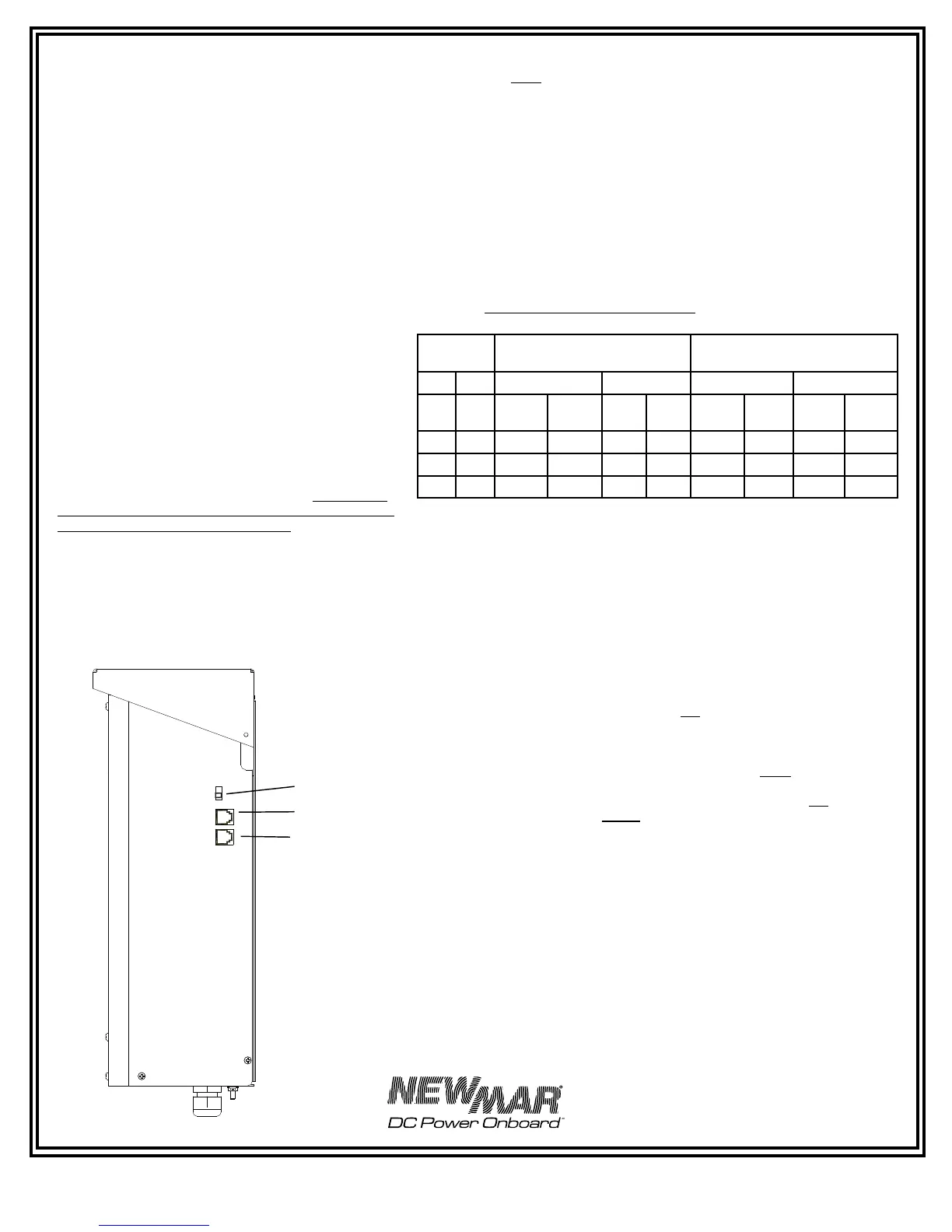

The remote sensor is provided with 30’ of cable. One end of the

cable is plugged into the temperature compensation jack which is

located on the right side of the charger (see FIGURE 6). The location

of temp sensor jack is identified on the front panel.

If additional cable length is required, additional cable is

commonly available from most electronics supply retailers such as

Radio Shack/Tandy. Request a 6 conductor modular-to-

modular line cord (part number 279-422, 25 feet long)

and 6 pin modular in-line non-reversing coupler (279-

423).

The sensor itself should be mounted on the inside of the

battery box, or more ideally, mounted onto one of the

batteries using a clamp or a small amount of silicon-

type adhesive. The sensor has a hole in the center which

will accommodate a # 6 screw. If you have access to

the exterior of a wall of the battery box, you may drill

a hole in the wall of the box and run the screw through

to mount the sensor onto the interior wall. Use caution

when drilling so that you do not accidentally puncture

the case of any battery inside the box.

Important note: When wiring multiple chargers in parallel (see

section III-E) and using the temperature compensation option,

you must use a separate sensor for each charger, and the sensors

must be mounted close together in the same battery box or on the

same battery for proper operation.

Without the temperature sensor installed the output of the charger

will be at the nominal voltages specified in the chart below at 72°

F (22.2° C). The absorption/float output voltage settings at that

temperature are listed in the chart.

To provide some examples which clarify the effect of the

temperature compensation sensor, the chart lists the absorption/

float output voltages of the charger when batteries are at 72° F (or

when the sensor is not installed), and at cold (50° F) or hot (90° F)

battery temperatures with the sensor installed:

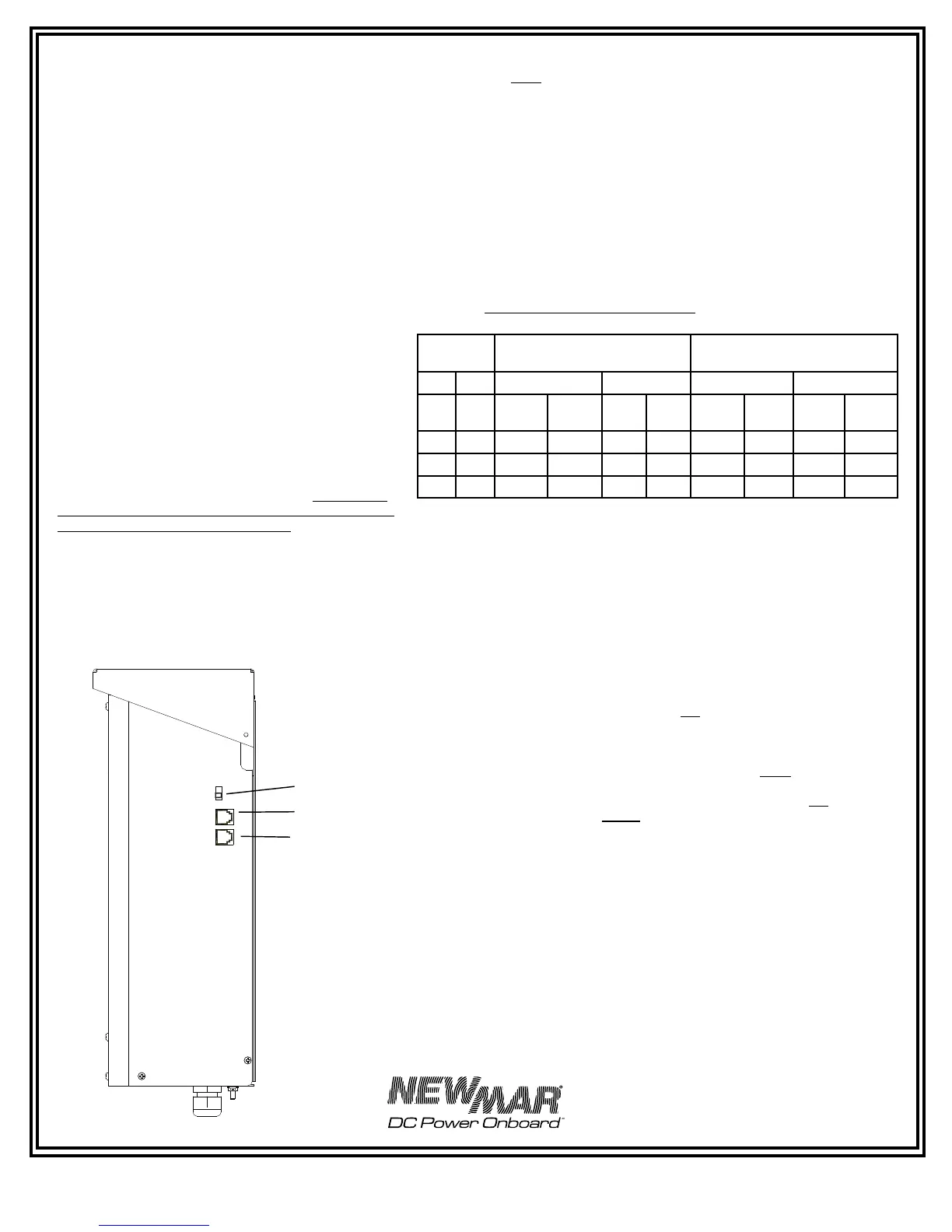

Temperature Compensation Chart

* Factory pre-set voltages without temperature compensation

option installed

FIGURE 6: Temperature Compensation Sensor

and Remote Panel Installation

F) Equalize Timer Option

Some manufacturers of flooded lead-acid batteries recommend

a charging process known as equalization for extended battery

life. This process involves occasionally charging a wet lead-acid

battery at a very high voltage for a short period of time in order

to completely de-sulphate each of the battery plates, essentially

equalizing their voltage. The installer of the Phase Three charger

may choose to wire in this option at the time of installation.

Note: The equalization process is not recommended for sealed

valve regulated or gel-cell batteries.

The equalize circuit (connector located inside the PT charger)

should be wired through a manual or electric timer which

provides a closed contact when engaged and an open circuit

when timed out (SPST — Single Pole Single Throw). Do not use a

manually operated switch for activating the equalize circuit. This

is because unless the charger is reverted to a safe float voltage in

a timely manner, the batteries will almost certainly be damaged

or destroyed. The timer should be a 0-12 hour type, capable of

carrying a minimum of 100 mA at 5V D.C.

CAUTION: Do not install the timer in an area requiring ignition

protected equipment unless it has been certified to meet ignition

protection requirements.

The equalization circuit of the Phase Three charger boosts output

voltage to approximately 8 % above float voltage. Refer to the

battery manufacturer’s instructions when deciding the appropriate

time period setting for this voltage to achieve proper equalization,

while ensuring batteries are not damaged by increased battery

temperature. This installation should only be performed by a

qualified technician.

Battery

Temp.

Output V D.C: 12 Volt Models Output V D.C: 24 Volt Models

Charge Float Charge Float

° F ° C Gel-

Cell

Lead

Acid

Gel-

Cell

Lead

Acid

Gel-

Cell

Lead

Acid

Gel-

Cell

Lead-

Acid

50 10 14.4 14.6 14.0 13.8 28.8 29.2 28.0 27.6

72 22.2 14.0* 14.2* 13.6* 13.4* 28.0* 28.4* 27.2* 26.8*

90 32.2 13.7 13.9 13.3 13.1 27.4 27.8 26.6 26.2

Loading...

Loading...