P.O. Box 1306, Newport Beach, California 92663 • Phone: 714-751-0488 • Fax: 714-957-1621 • E-Mail: techservice@newmarpower.com

www.newmarpower.com

5

*Per ABYC A-31: A D.C. chassis grounding conductor shall be

connected from the case of the battery charger to the engine

negative terminal or its bus, and must not be more than one size

under that required for the D.C. current-carrying conductors, and

not less than 16 AWG.

Make a mark on the wall or bulkhead where each of the

keyhole slots will be located. Then drive a screw about halfway

in at each of these marks. Hang the charger onto the bulkhead

using the keyhole slots. Doing this will save you from having to

support the charger’s weight while you are driving in the four

permanent mounting screws. Note: The keyhole slots may be

used for additional support screws but they are not to be used as

permanent mounting points by themselves.

IMPORTANT: Although the charger is constructed of materials

and in a manner which makes it highly resistive to the corrosive

effects of moisture in the environment, the charger is not water-

resistant. Do not mount the charger where there is a possibility of

water entering the unit. Evidence of water entry into the charger

will void the warranty.

D) D.C. Output Wiring

Note: Only qualified service personnel should access the output

terminals of the charger.

Whether working with existing battery charger output wires or

installing new ones, make sure the battery(s) is disconnected

from these wires before connecting them to the charger’s output

terminals.

For secure installation D.C. output wires must be attached with ¼”

crimp ring lug terminals sized appropriately to fit wire gauges as

listed below.

The D.C. wire size table below may be used to determine the

correct gauge wire based on the model you have and the length

of wire run from the charger to the batteries. Once the output

wiring has been attached to the chargers output posts, install the

clear plastic terminal cover provided with the charger

Model Length of Wire from Charger to Batteries (in feet)

10’ 15’ 20’

Minimum Wire Gauge AWG (mm)

PT 80 #2 (35mm) #1 (50mm) #1/0 (70mm)

PT-24-45U #6 (16mm) #6 (16mm) #4 (25mm)

PT-24-95U #2 (35 mm) #2 (35 mm) #2 (35 mm)

*Based on N.E.C. Minimum Wire Size Chart and ABYC 3% Voltage

Drop Chart

ENSURE THAT LEADS ARE PROPERLY FUSED AT THE BATTERY.

(REFER TO ABYC RECOMMENDATIONS.)

A note about the internal D.C. fuse: The internal wiring of the

Phase Three charger is protected against dangerous overheating

in the event of an internal short, or reverse polarity hook-up, by an

internal d.c. fuse. The fuse is not user replaceable. If this fuse blows

the unit must be returned to NEWMAR or a qualified electronic

technician for repair.

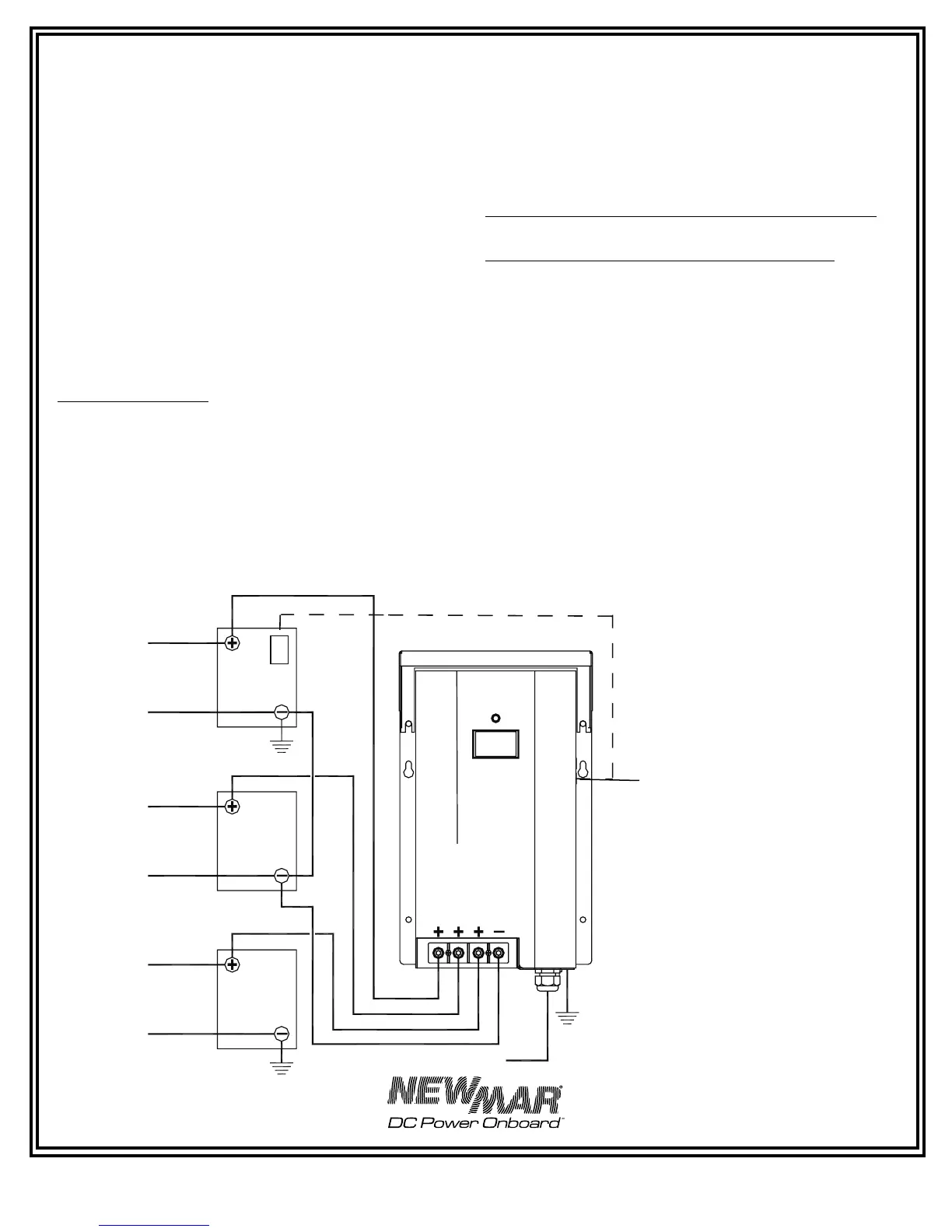

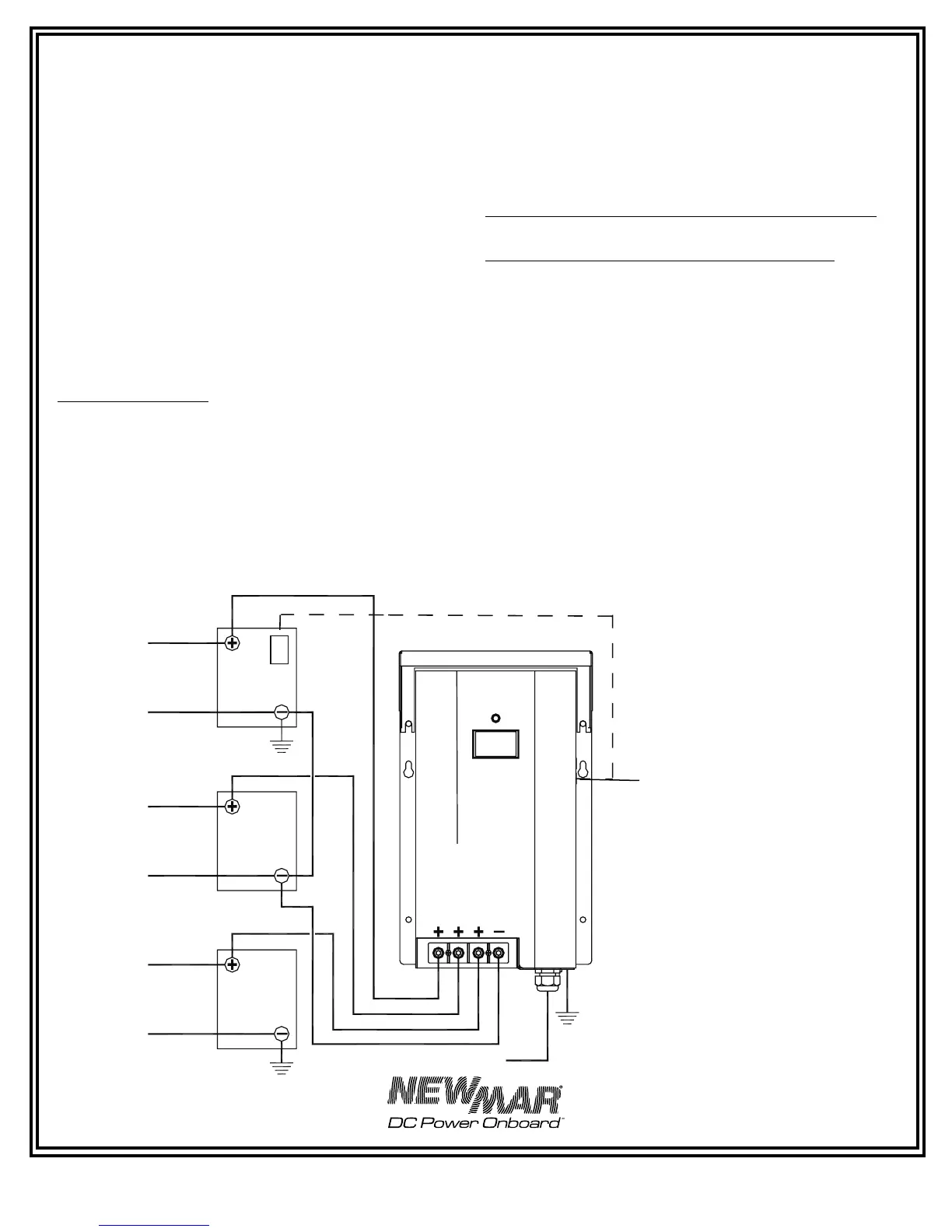

Typical D.C. wiring configurations are illustrated in FIGURES

1 and 2.

FIGURE 1: Simple D.C. Wiring (Preferred Method)

Phase

Thre

e

Battery

Charter

T

C

S

AC Input

House

Bank 1

House

Bank 2

Gen

Bank

B

A

T

T

1

B

A

T

T

2

B

A

T

T

3

C

O

M

M

O

N

*

* Per ABYC A-31: A D.C. chassis grounding

conductor shall be connected from the case

of the battery charger to the engine negative

terminal or its bus, and must not be more

than one size under that required for the D.C.

current carrying conductor and not less than

16 AWG

Note: This diagram does not illustrate a

complete system. Refer to ABYC standards

E-11 AC & DC electrical system on boats

Important: Install fuses at batteries per ABYC

recommendations.

Optional Temperature

Compensation Sensor See page

9 for installation information. Use

provided cable clamps to secure

probe cable

Note: PT 80/PT-24-45U

illustrated, same configuration

applies to PT-24-95U.

Loading...

Loading...