4-19

4.1.5 Dielectric Absorption Ratio (D.A.R. Test)

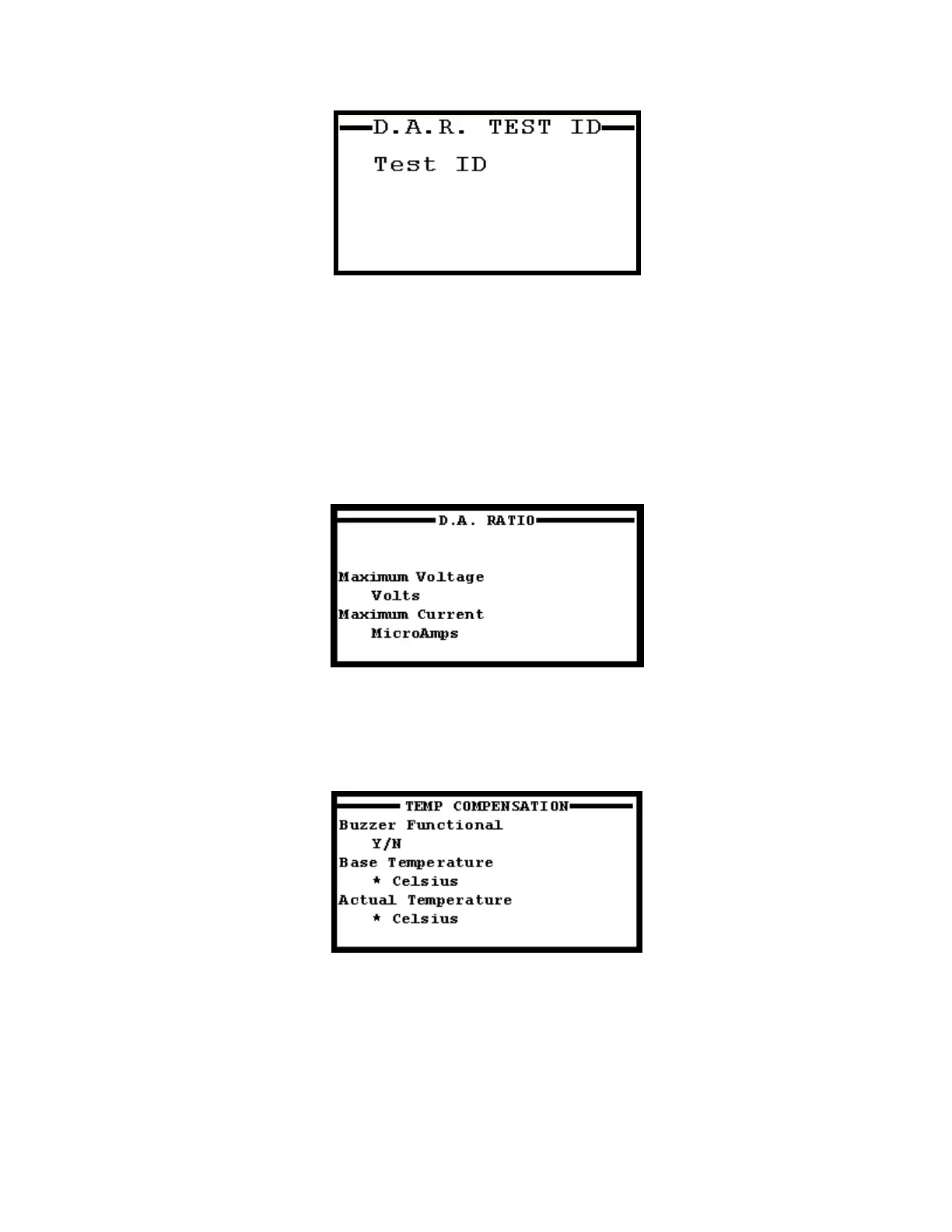

Figure 40: Dielectric Absorption Ratio Test I.D. Screen

Enter an alphanumeric test identification (or leave blank) and press enter.

In good insulation systems, it is expected that the insulation resistance increases as the time dependant

charging currents approach zero. Generally, insulation systems that are degraded show low resistance values

even after a considerable amount of time has elapsed. The time dependant Dielectric Absorption Ratio can

provide a good indication whether the insulation system has a problem. By taking a resistance measurement

at 30s and a resistance measurement at 60s and calculating the ratio of the two readings, a determination of

the insulation quality can be made. Typically D.A.R. values lower than 1.25 warrant further testing and

evaluation.

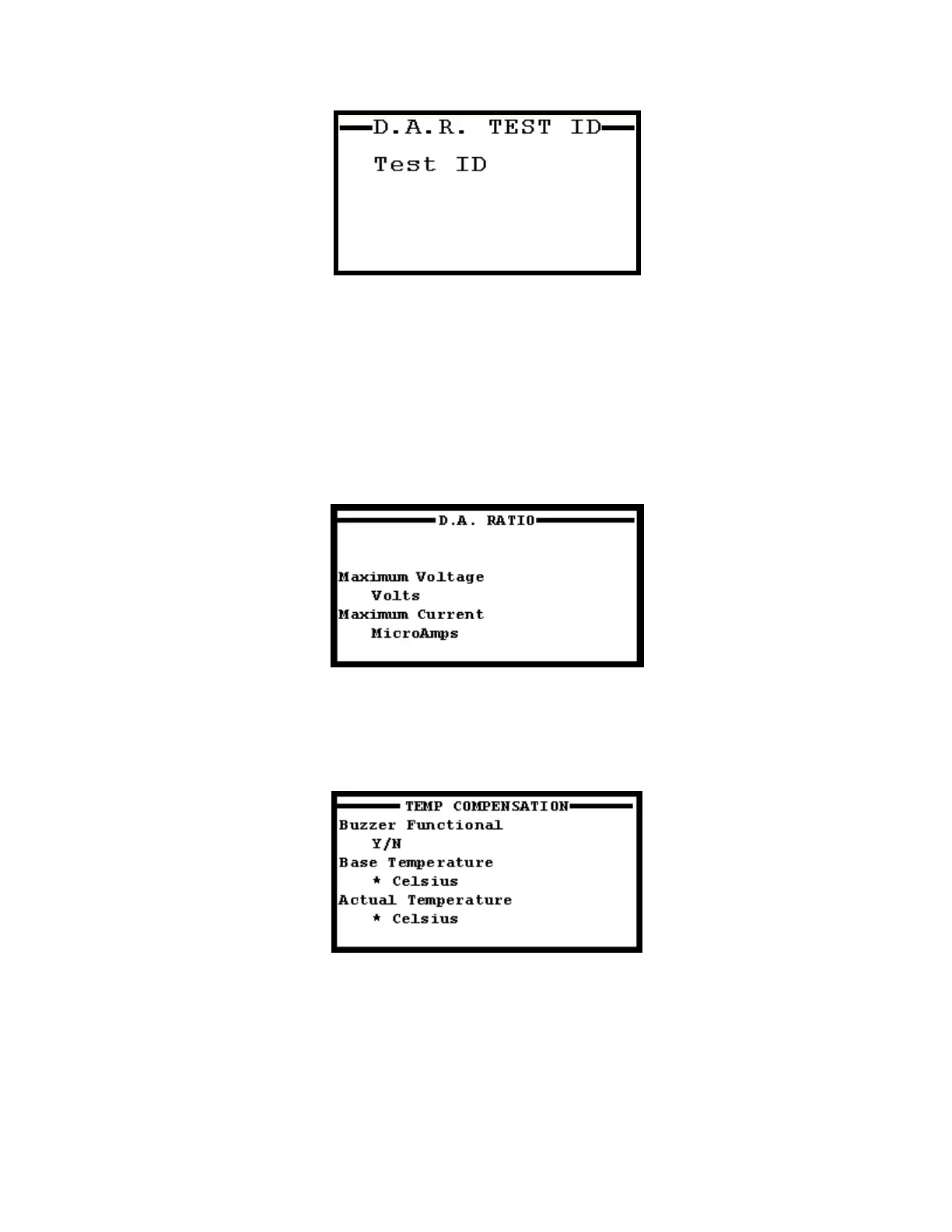

FIGURE 41: Dielectric Absorption Ratio Setup Screen

At the Dielectric Absorption Ratio Setup Screen (Figure 41), enter the maximum voltage to apply and the

maximum allowed current for the Overcurrent Trip. Press Enter to cycle through the Temperature

Compensation Setup Screen.

FIGURE 42: Temperature Compensation Setup Screen

At the Temperature Compensation Setup Screen (Figure 42), the operator can choose to activate the internal

buzzer to sound during the test. Inputs are Y for buzzer on and N for buzzer off. Users can then define a

base temperature to correct resistance measurements to, as well as the actual temperature of the test object.

These fields must be completed, as leaving them blank does not bypass the temperature compensation

function of the unit. It is recommended not to correct to a temperature more than ± 20°C from the test

objects temperature, as this could cause significant error in the resistance reading. Once the Temperature

Compensation screen is filled out, press Enter to bring up the HV Waiting Screen.

Loading...

Loading...