7

9

↑

WING TIP

6. Temporarily position the aileron servo into the

servo bay. Drill a 1.6mm hole through the four

mounting holes of the servo, drilling through the

plywood mounting plate in the wing. Install and

remove a servo mounting screw into each of the

four holes. Insert a drop of thin CA into the

holes to harden the wood. After the glue has

cured, install the servo into the servo bay using

the hardware that came with your servo. Center

the servo and install a servo arm as shown.

7. Repeat step # 1 - # 6 to install the second

aileron servo in the opposite wing half.

3. Repeat step # 1 - # 2 to install the control horn

on the second aileron.

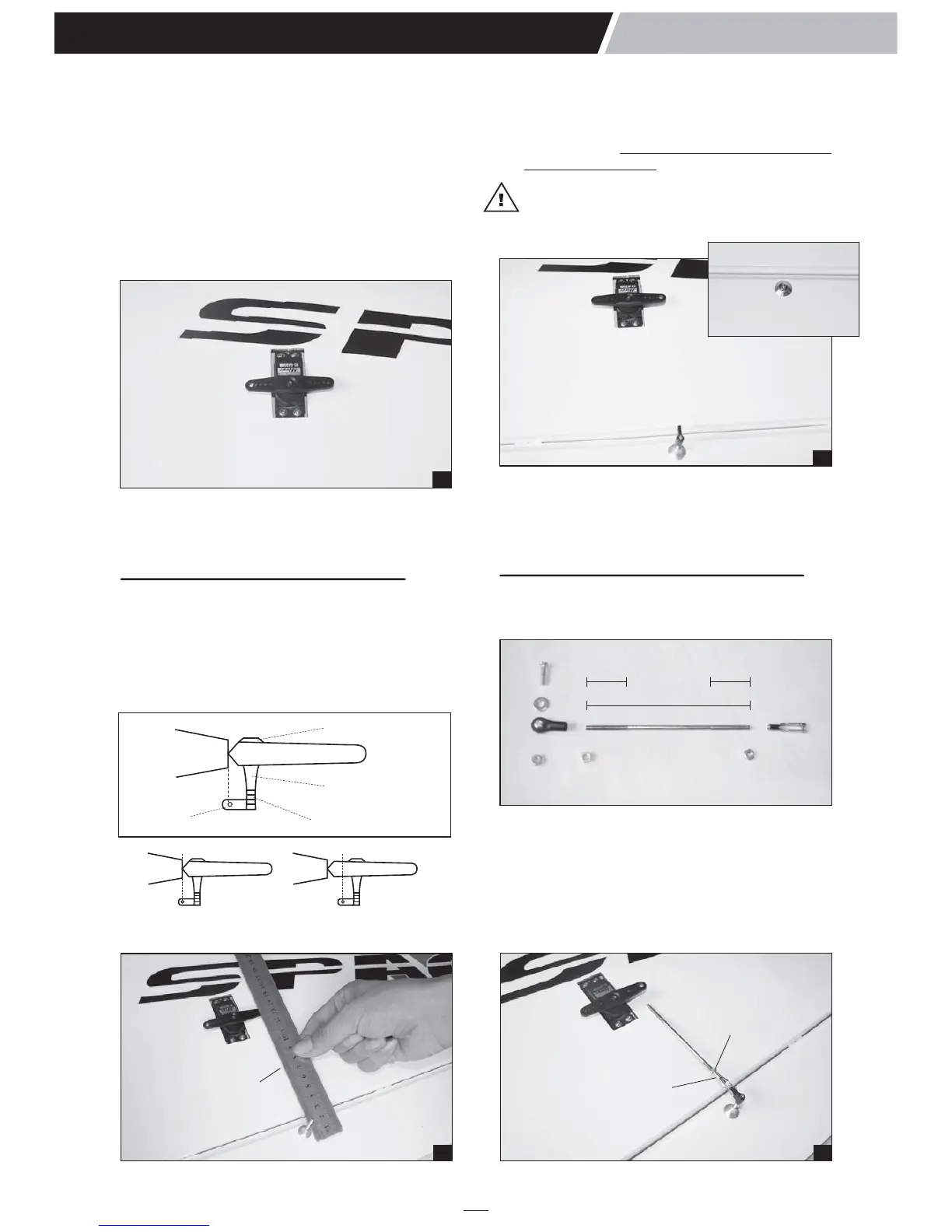

INSTALLING THE AILERON LINKAGES

The aileron linkages are assembled as shown

below.

1. Locate the pushrod wire. Slide a silicon clevis

retainer onto a clevis. Screw a M3 nut and a

threaded metal clevis onto the threaded end of

the wire. Tighten the nut against the clevis and

then install the clevis on the aileron control

horn.

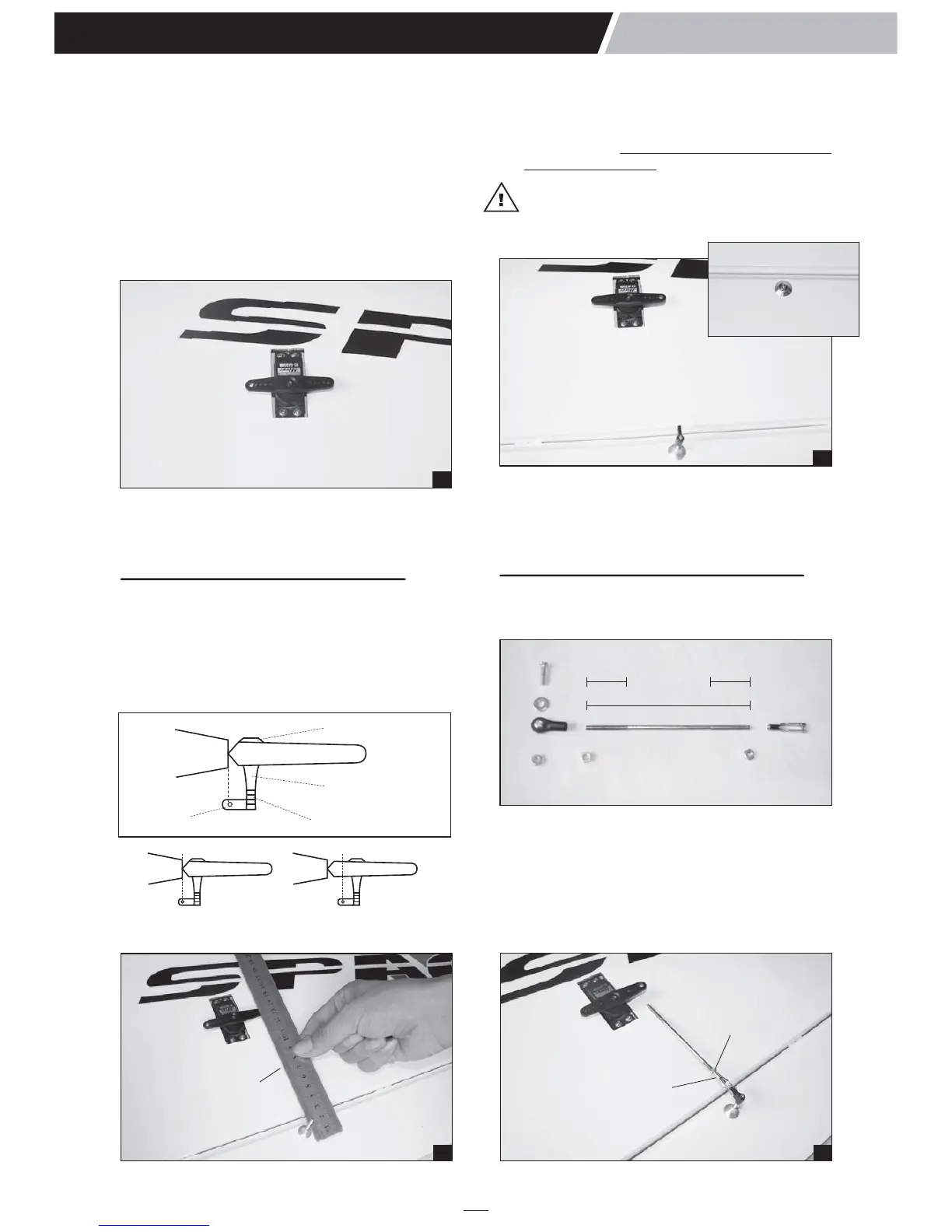

INSTALLING THE CONTROL HORNS

1. The aileron has a block wood plate for mounting

the control horn. One aileron control horn in

positioned on each aileron. Using a ruler and a

pen, locate and mark the location of the control

horn. It should be mounted on the bottom side

of the aileron at the leading edge, in line with

the aileron pushrod.

7

4

EXTRA 300S

Instruction Manual

2. Drill through the mark you made with a (3mm)

drill bit. Hard the hole with thin CA. Install the

control horn. Remember use thread locking

compound to secure.

Note: The hole on the nylon horn is aligned

with the hinge line and pushrod is aligned with

the servo arm.

10

M3 nut

M3 clevis

95mm

22mm

22mm

Aluminum washer

Aluminum control

Plastic horn

3mm Screw

RIGHT WRONG

8

IN LINE

↑

WING TIP

↑

WING TIP

Loading...

Loading...