9

36

INSTALLING THE THROTTLE PUSHROD HOUSING

1. Place the engine into the engine mount and

align it properly with the front of the cowling.

The distance from the firewall to the front of the

engine thrust washer should 110mm.

If your engine is equipped with a remote needle

valve, we suggest installing it into the engine at

this time.

2. When satisfied with the alignment of the engine,

use a pencil and mark the mounting hole

location onto the firewall, where the throttle

pushrod will exit.

3. Now, remove the engine. Using a 5mm drill bit,

drill holes through the firewall and the forward

bulkhead at the marks made.

4. Slide the pushrod housing through the hole in

the firewall, through the hole in the forward

bulkhead, and into the servo compartment.

5. Apply a couple of drops of thin C/A to the

pushrod

housing where it exits the firewall and where it

passes through the forward bulkhead. This will

secure the housing in place.

6. Using a modeling knife, cut off the nylon

pushrod

housing 26mm in front of the servo tray.

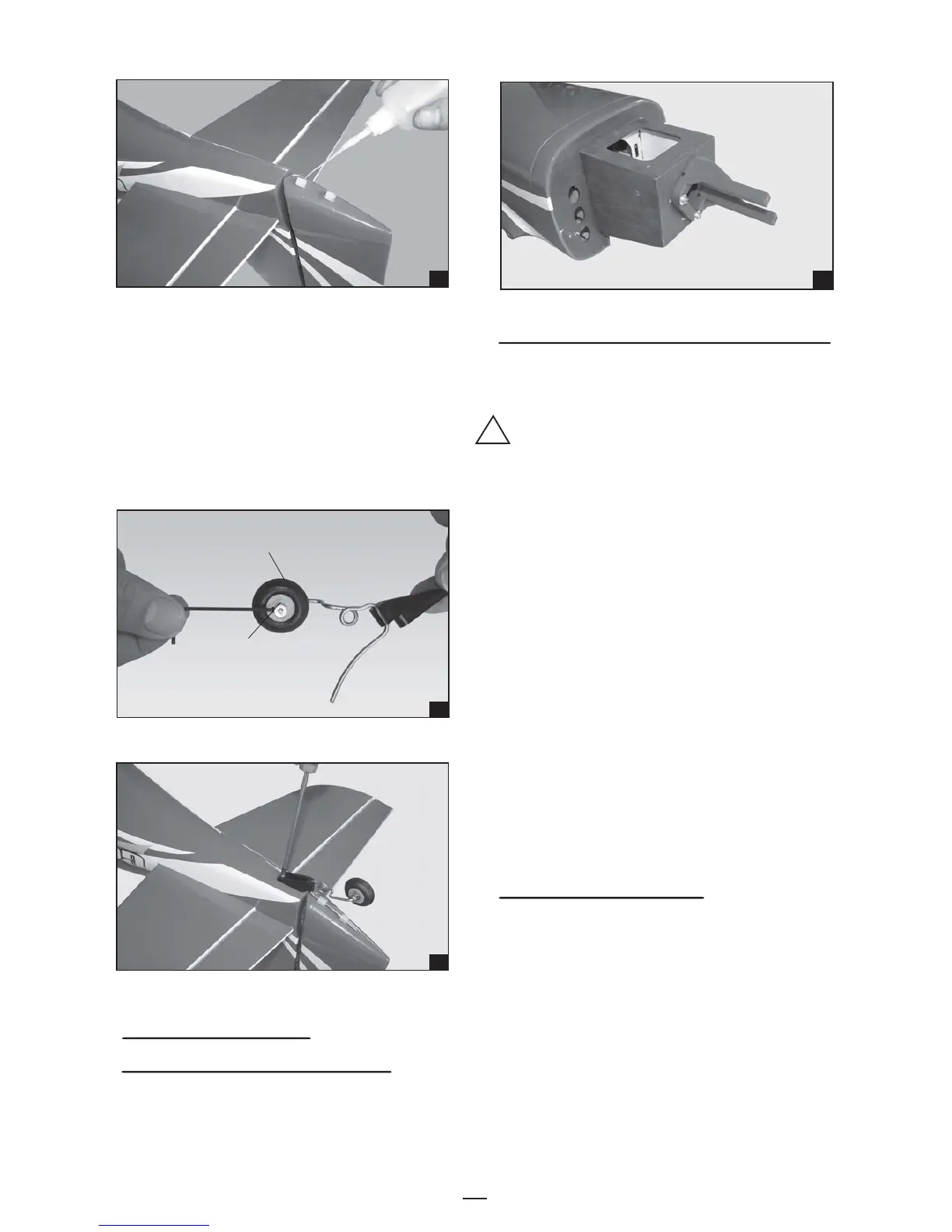

INSTALLING THE ENGINE

Locate the long piece of wire used for the throttle

pushrod. One end of the wire has been

pre-bend in to a "Z" bend at the factory. This

"Z" bend should be inserted into the throttle

arm of the engine when the engine is fitted onto

the engine mount. Fit the engine to the engine

mount using the screws provided.

!

ENGINE INSTALLATION

Installing the engine mount

Install the engine mount using 4 screw 4mm x 25mm

33

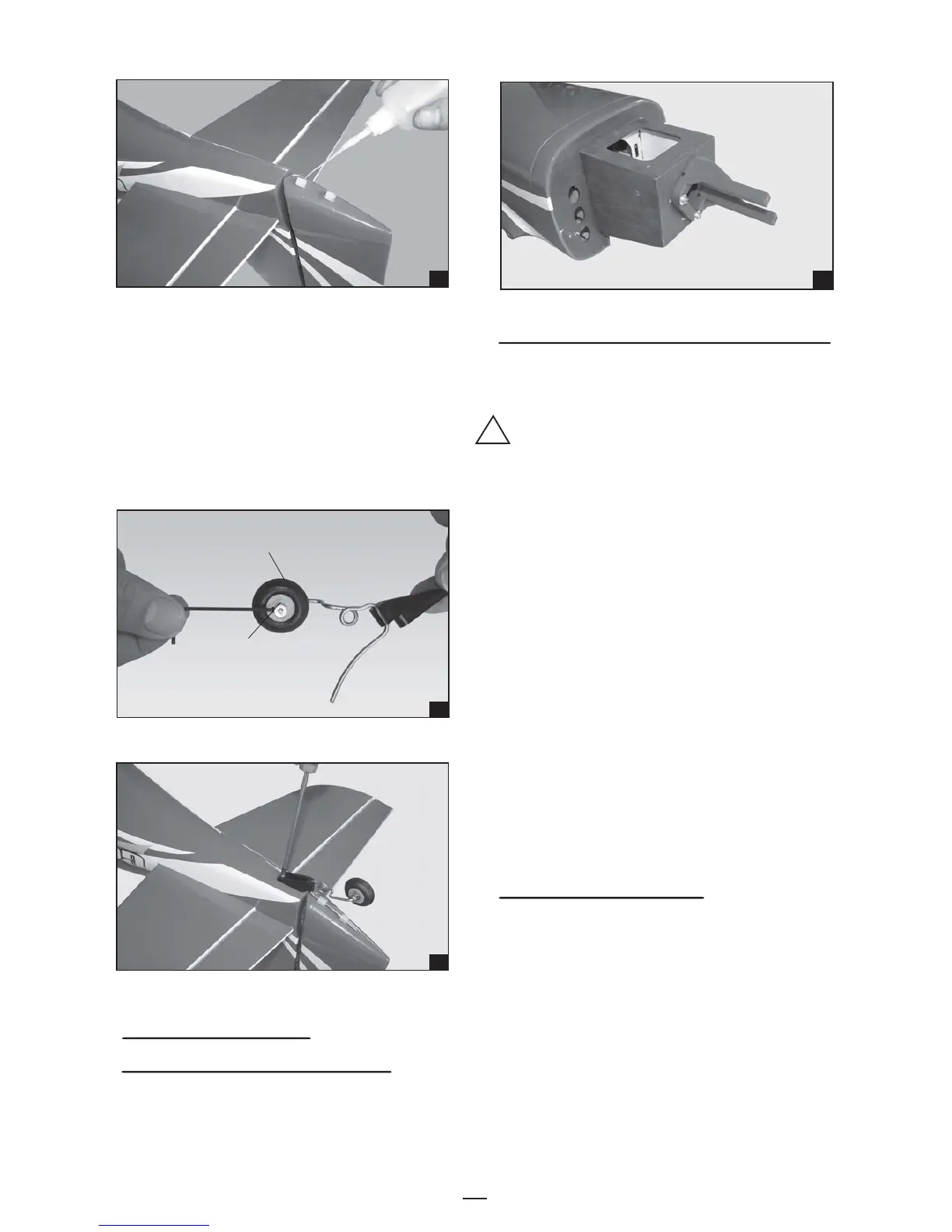

2. Set the tail wheel assembly in place on the

plywood plate.

3. Drill 2,6mm pilot holes through the plywood

plate.

4. Secure the tail wheel bracket in place using two

3mm x 12mm screw.

5. Align the tail wheel wire so that the wire is

parallel with the bottom of the rudder.

34

Wheel

Collar

35

Loading...

Loading...