19

PORA ELECTRIC MACHINERY CO.,LTD.

PR-DTC-3000 Type

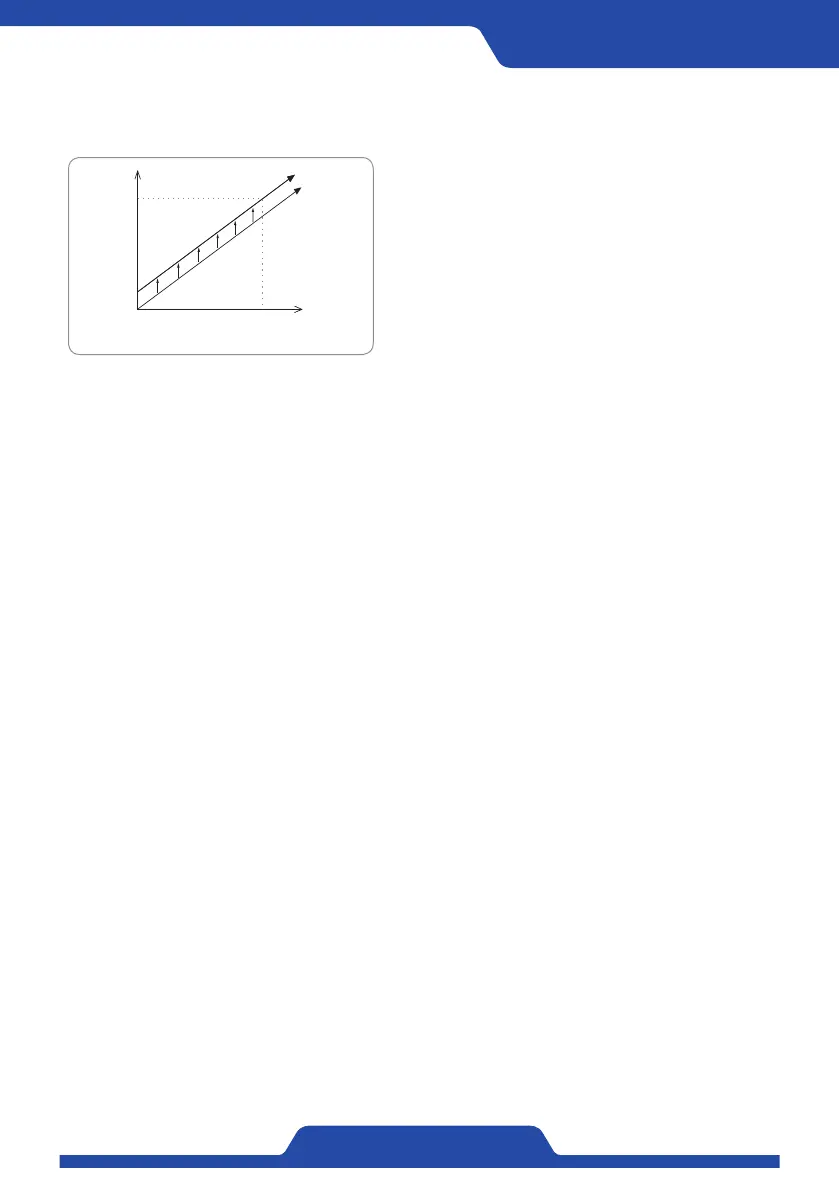

The start voltage is changed from 0V to 4V

4) When the starting voltage in the basic setup is changed

7

7

DPVOU

45"3570-5

45"3570-5

065165

(SBEJFOUWPMUBHF

4.Check Up, Trial Run & Adjustment

1)Initial Check-up

- All power OFF

-Check for selection of powder brake/clutch suitable for the capacity

-Before operation, check if the tension controller, applying loads and sensor are properly arranged.

- The capacity of the applying loads is established based on the values of the [Line Speed X Operational

Tension]. However, as the tension controller can set over these values, it can cause malfunctioning of the

load device. Accordingly, it is important to ensure the operator has a clear understanding of the extent to

which the unit can be operated based on the heat capacity of the applying loads.

- When the tension is set too low, it can cause vibration of the unit or instability at stop, the operator should be

well aware of the appropriate level of the bottom limit.

2)Menu Set Up

- With the power for the controller ON

The tilt voltage of the material, start voltage and the rate voltage are to set as described on pages 13.

3)Trail Run

- With all power ON

Provide the controller with a certain level of the output at Manual mode and check normal operation of the

machine including the direction of the motor’s rotation.

4)Automatic Operation

- With all power ON

Conduct the automatic operation as described on In order to prevent any malfunctioning during operation.

However, set up the parameters and select the materials after the machine stops.

Loading...

Loading...