ENGLISH

11

Straight Cuts

1. Using a marker or grease pencil, mark the area to be cut

ontile.

2. Place the tile on the cutting cart against the cutting cart

fence

9

and align your mark with theblade.

3. Pull the on/off switch up to turn the saw on and wait for

the blade to be completely covered withwater.

4. Ease the cutting cart toward the blade then slowly feed

the tile into the blade. Continue pushing until the blade

cuts completely through thetile.

NOTE: The flip hood on the splash hood can be rotated

up to help align the line on the tile with the blade.

5. Turn off thesaw.

Diagonal Cuts

Diagonal cuts are also referred to as “long point to long

point cuts.”

1. Install the edgeguide.

2. Align the point of the tile closest to the cutting cart

fence

9

with the cut indicator

32

.

3. Align the front of the tile to the blade and hold against

the edgeguide.

4. Turn the saw on and make thecut.

5. Turn off thesaw.

L-Cuts

An L-cut is a section that is removed from of a piece of tile

and is used when cutting a piece of tile to fit in a corner of a

cabinet or piece of trimmolding.

1. Outline the area to be cut on both sides of thetile.

2. Align the tile to the cutting cart fence and make the cut

far enough into the tile withoutovercutting.

3. Make a cut on the other mark on the tile

withoutovercutting.

4. Turn the tile over and make the cut along one of the

outlines, but this time an overcut can occur without

damaging the exposed surface of the tile due to the

radius of the blade. Overcut the other line and the cut

piece should be separate from the rest of thetile.

5. Turn off thesaw.

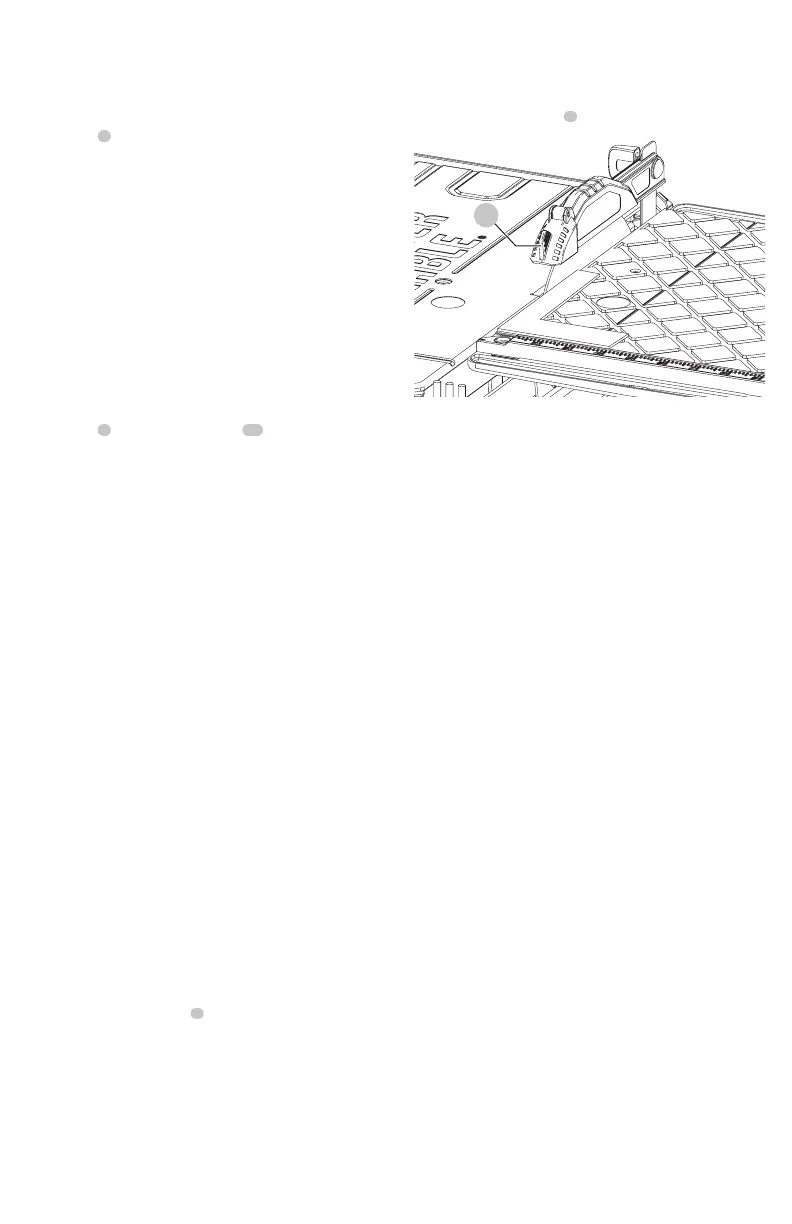

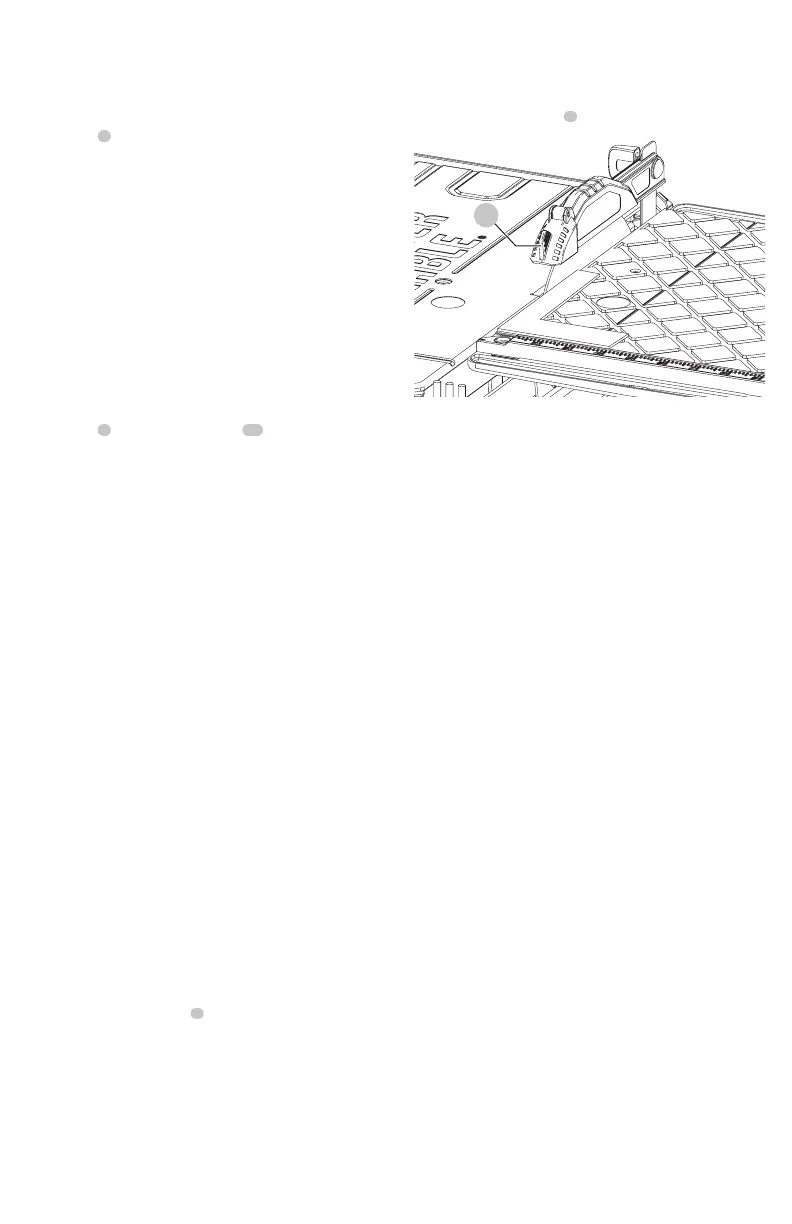

Adjustments (Fig.A, S)

The cutting cart fence and rails are properly aligned from

the factory. Shipping or prolonged use can cause them to

become misaligned and needadjustment.

Squaring the Cutting Cart Fence to the

Blade

1. Lay a 90º square flat on the blade surface with one end

against the cart fence

9

.

2. If the blade is not 90º to the cart fence, the rail will

needadjustment.

3. Loosen the cart fence adjustmentscrew.

4. Adjust the fence until it is square to theblade.

5. Tighten the cart fence adjustmentscrew.

Adjusting the Cutting Cart Parallel to

the Blade

1. Lay a 90º square flat on the blade surface with one end

against the cart fence

9

.

FIg. S

32

2. If the blade is not 90º to the cart fence, the rail will

needadjustment.

3. Loosen the three front and rear screws on the left guide

rail, and adjust rail until it is parallel to theblade.

4. Move the rail until the cart fence is square to theblade.

5. Tighten the three railscrews.

MAINTENANCE

WARNING: To reduce the risk of serious personal

injury, turn tool off and remove the battery pack

before transporting, making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can cause injury. Make sure the

switch is in the OFFposition.

Lubrication

WARNING: NEVER spray or in any other way apply

lubricants or cleaning solvents inside the tool. This can

seriously affect the life and performance of the tool

and may result in personalinjury.

PORTER-CABLE tools are properly lubricated at the factory

and are ready for use. However, it is recommended that,

once a year, you take or send the tool to a certified service

center for a thorough cleaning andinspection.

Cleaning

WARNING: Blow dirt and dust out of all air vents with

clean, dry air at least once a week. To minimize the risk

of eye injury, always wear ANSI Z87.1 approved eye

protection when performingthis.

WARNING: Never use solvents or other harsh

chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic

materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid

get inside the tool; never immerse any part of the tool

into aliquid.

Loading...

Loading...