- 16 -

1)

optional equipment

(362) 9700-GB WARTUNG

MAINTENANCE

GB

General maintenance hints

In order to keep the implement in good condition after long periods of

operation, please observe the following points:

Safety points

• Turn engine off when adjustment, service and repair work is to be

done.

• Do not work under the machine without safe support.

- Retighten all screws after the first hours of operation.

- Tighten all screws after the first hours of operation.

Check blade screws in particular.

- Observe maintenance hints for angular gear and cutter bar.

Spare parts

a. The original components and accessories have been

designed especially for these

machines and appliances.

b. We want to make it quite clear

that components and

accesories that have not been

supplied by us have not been

tested by us.

c. The installation and/or use of

such products can, therefore,

negatively change or influence the construction characteristics of

the appliance. We are not liable for damages caused by the use

of components and accessories that have not been supplied by

us.

d. Alterations and the use of auxiliary parts that are not permitted by

the manufacturer render all liability invalid.

Asbestos

- Certain sub-supplied components of the vehicle

may contain asbestos due to technical reasons.

Observe the warning on spare parts.

TD45/94/24b

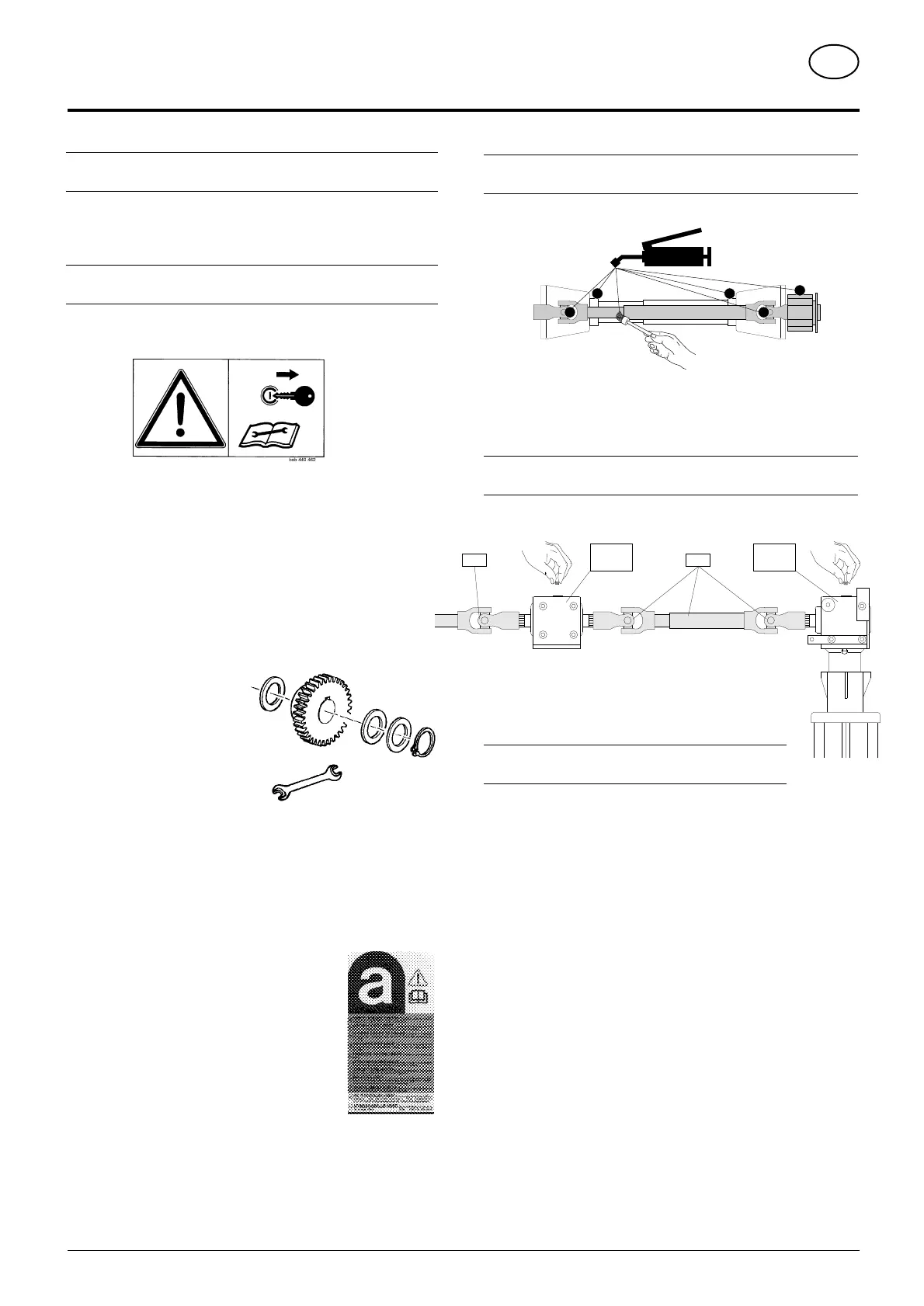

GWGW

0,8 Liter

SAE 90

1,2 Liter

SAE 90

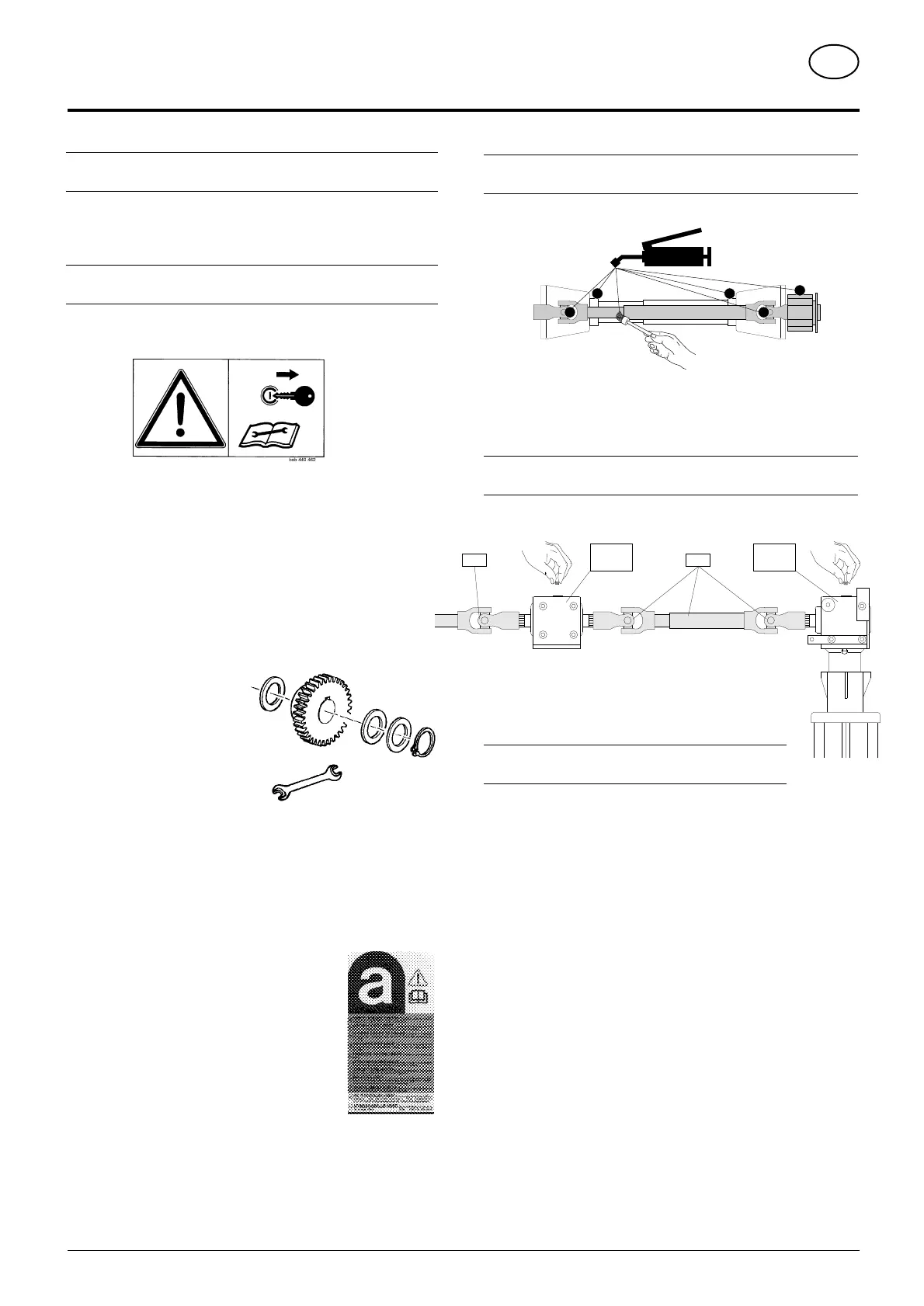

Drive shaft

- Lubricate drive shaft every 8 hours of operation.

- Pull sliding sections apart and grease well.

Cardan shafts

- Lubricate both shafts (GW) every 20 hours of operation.

- Pull sliding sections apart and grease well.

Gear

- Change oil after the first 50 operating hours.

Under normal operating conditions, oil is to be replenished annually.

- Change oil after 300 ha at the latest.

8

h

FETT

Loading...

Loading...