Scroll Enclosure Air Compressor 15-60 HP

Operating & Maintenance Manual

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN596202AV • 21 February 2023

Page 12 of 32

1. Switch the breaker OFF if the compressor is not to

be used for a long period of time.

Stopping the Compressor During Emergency

Operation

Stop the compressor by pushing the OFF button or

by turning the power o at the main disconnect panel.

Multi-stage Control

As this compressor uses plural air ends, it employs

multi-stage control. It can start and stop each air

end according to pressure and air consumption,

automatically select the number of air ends in

accordance with air consumption and achieve optimum

and uniform operation at all times as well as energy-

saving and labor-saving operation.

1. Multi-stage control - Among air ends which are

operating under group control, it stops the air

end which has been operating for a longer time

and restarts the air end whose operating time

has been shorter, thus resulting in equalization

of operating time of each air end and operation

with a min. quantity of air ends in accordance with

air consumption and energy-saving operation by

eliminating waste of electricity. Table 3 on page 11

shows the relationship between pressure and the

quantity of air ends operating for an SEO model.

The same concept is applied to 6 air ends for an

SEH.

2. Automatic Alteration: When air demand allows

one or more air ends to remain idle, the control

will automatically shift operation to equalize

usage after 10 minutes. If air demand increases

and pressure drops, the control will energize

additional air ends as needed, starting the one

with the longest o time rst. The control will also

de-energize air ends as pressure rises.

3. The control allows the user to adjust the pressure

settings. To minimize power consumption,

the user should select the lowest maximum

pressure that is suitable for the operations being

performed. The smallest gap between minimum

and maximum pressure that avoids too frequent

motor starting should also be selected.

4. The control will automatically prevent multiple

motors from starting simultaneously by inserting

a three second delay.

Operating Panel & Settings

The Scroll Enclosure Air Compressor is controlled

by a PLC programmed at the Powerex factory. The

operating status is displayed on the HMI– touch screen

panel on the front of the compressor unit. The touch

screen allows the user to select operating parameters

within predetermined limits set at the factory. The

touch screen also allows the user to change the display

to get more information about the operation of the

individual compressor modules and to take action

based on alarms and warnings. This enclosed scroll

system utilizes a PLC for alternation and will change

the pump sequence (Lead, Lag1, Lag2 etc) after every

start or after 10-minutes, which ever happens rst. The

HMI oers a MIN and MAX system setpoint and three

calculated pressure dierential settings. (Standard, Min

and Max).

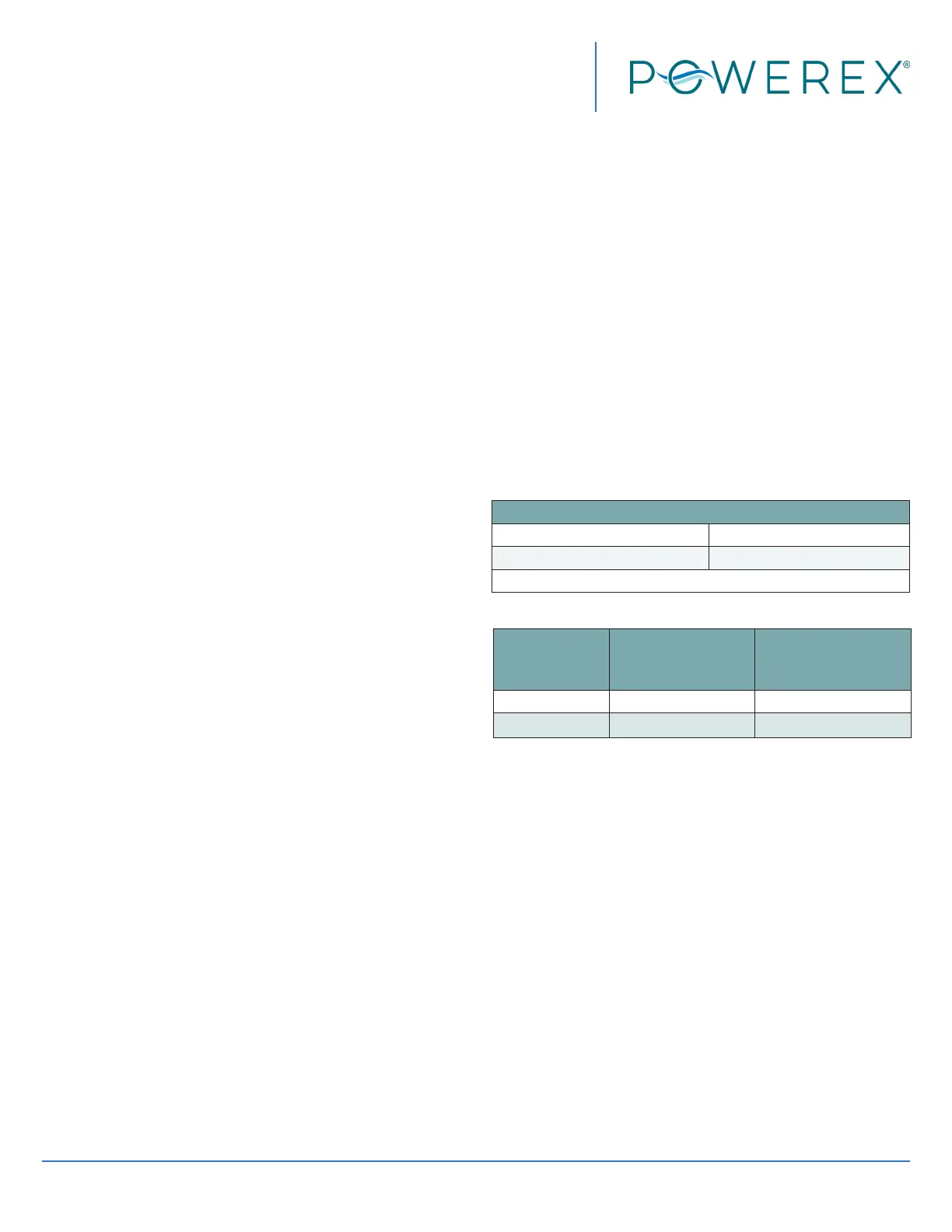

The factory default sengs for HIGH and LOW Operang Pressures

Standard Pressure 90-116 PSIG

High Pressure 95-145 PSIG

Dierenal seng default is STANDARD

Table 4

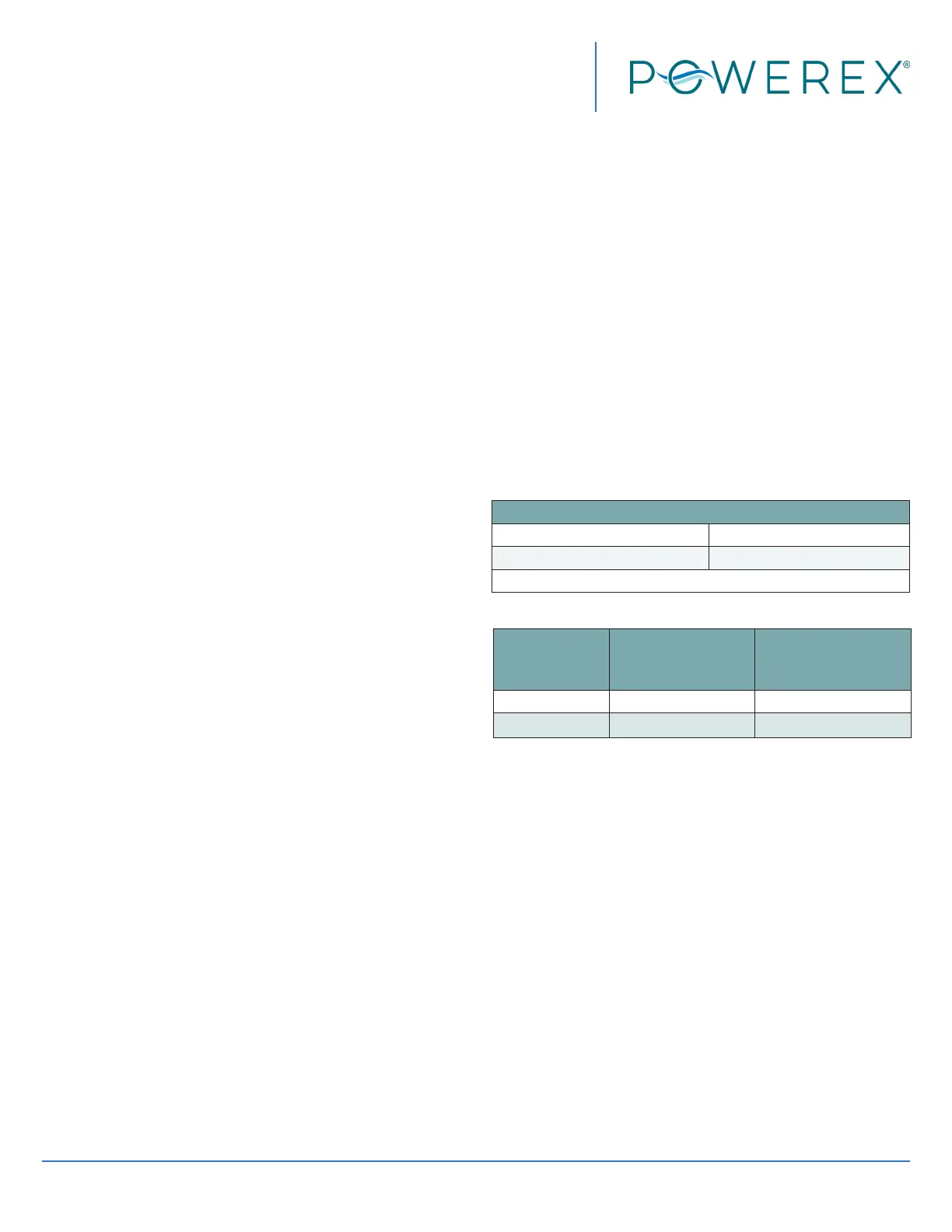

High Operang

pressure

(cut out seng) limits

Low Operang pressure

(cut in seng) limits

Standard Pressure 60-116 PSIG 50-96 PSIG

High Pressure 95-145 PSIG 79-129 PSIG

Table 5

The control automatically di\idcs the range between

HIGH and LOW Operating Pressure into equal operating

intervals. The dierential for the operating intervals

may be adjusted by selecting STANDARD, MIN or MAX

on the set up screen.

In STANDARD, the dierential will be automatically set

to have a slight overlap between the individual pump

intervals. Each interval will be 135% of the possible

minimum value.

In MIN, the dierential will be automatically set to

divide the available range into equal intervals with no

overlap. The selection will result in the most frequent

starting of the electric motors for a given Operating

Pressure range.

NOTE: more frequent motor starting can lead to

reduced motor life. Exceeding 17 .5 starts per hour will

cause a warning display.

Loading...

Loading...