Scroll Enclosure Air Compressor 15-60 HP

Operating & Maintenance Manual

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN596202AV • 21 February 2023

Page 7 of 32

3. Avoid connecting the safety valve with any tubing

or piping.

4. Manually operate the safety valve every six months

to avoid sticking or freezing.

Check Valves

Do not install a check valve between the compressor and

the air receiver or facility piping. If a check valve is installed,

the compressor pressure sensor will see rapid pressure

drops and cause short cycling of the motors and other

control problems.

Isolation Valves

An isolation valve should be installed between

the compressor and the air receiver to facilitate

maintenance. Make sure the valve is open when

operating the compressor. A second isolation valve

should be installed between the air receiver and the

facility piping.

Intake Air Connections

Powerex 7.5 and 10 HP Scroll enclosed models

normally have an intake lter assembled to each

compressor pump. These lters are located internal

to the sound mitigating compartment to provide

maximum protection for the pump and reduce noise

near the enclosed compressor system.

For models supplied with remote intake capability,

such as those used in Medical Air systems and other

special applications the pump intakes are routed

together and an externally mounted air lter assembly

is installed. This lter is provided with an isolation

valve so that if the unit is removed from service the

branch connection to the main intake header can be

closed. NOTICE operating the compressor unit with

the isolation valve closed will result in catastrophic

damage to the pumps. Powerex provides the valves

with the handle removed and stored in the system

control enclosure. We suggest utilization of this handle

be controlled to prevent accidental operation with the

valve closed. Multi-stack models such as the SEQ, SEP,

and SEH series will have a lter and valve for each stack.

Unit Vibration Isolation

Each pump motor assembly in the Powerex unit has

isolation mounting between its support rails and the

system frame. Additional isolation is not required, but

is allowable if desired. Powerex can supply cork rubber

composite mounting pads to use under the corners of

the base platforms if desired. Contact customer service

lines are covered. Before putting the unit into service,

nd and repair all leaks in the piping, ttings and

connections.

Select the size of the air receiver so that the combined

volume of

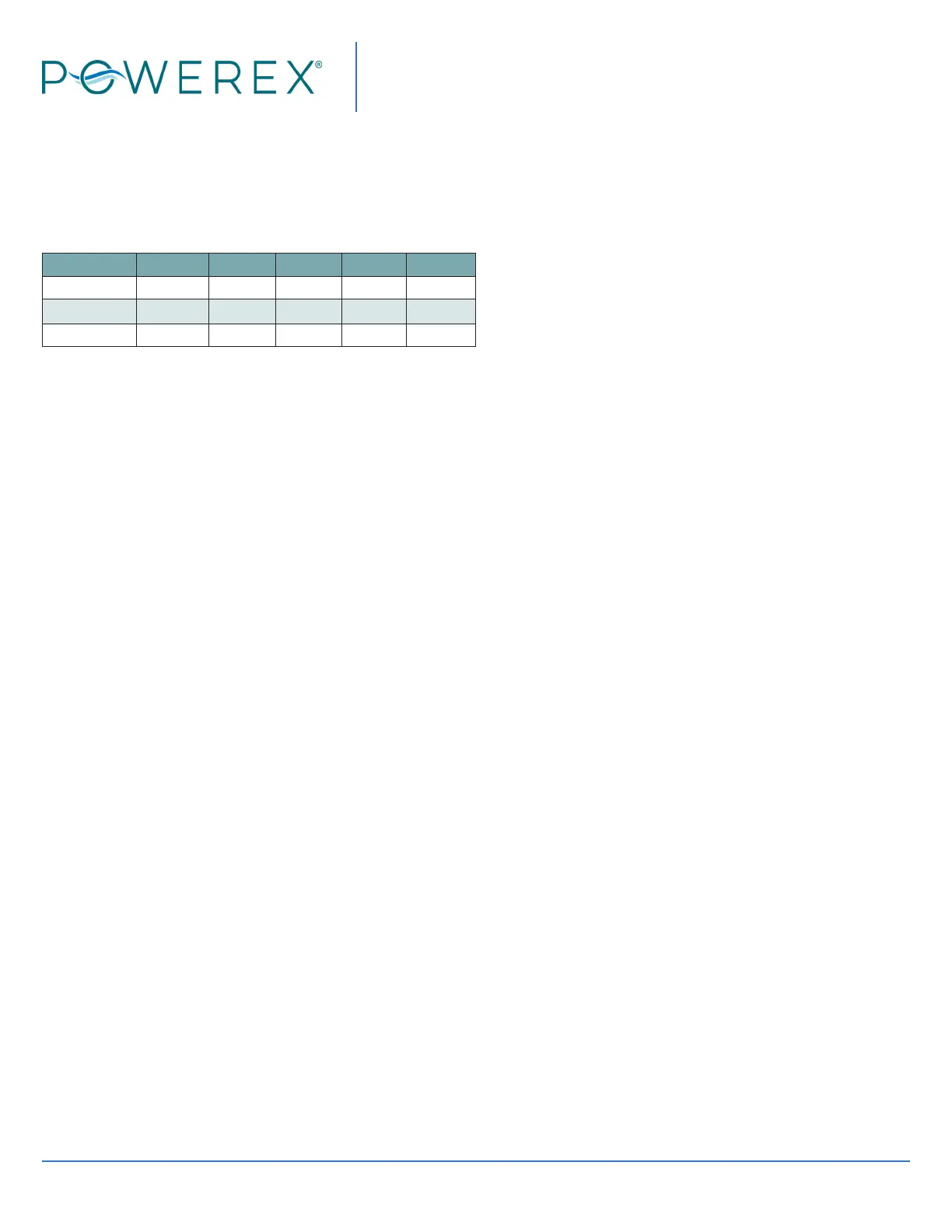

Dierenal* Duplex Triplex Quad Penta Hex

Min. 120 120 200 200 240

Standard 120 120 120 200 240

Max. 120 120 120 120 200

*Pressure seng selected on control panel

Table 2

the air receiver and facility piping results in a long

enough cycle time to keep any individual motor from

starting more than once every 3.43 minutes. Selecting

the widest possible spread between high and low system

set point pressure along with the largest dierential for

each pump interval will reduce the starting frequency.

The table below shows the recommended tank size

in gallons per model. Some conditions of air usage may

require additional volume.

1. Make sure the piping is lined up without being

strained or twisted when assembling the piping to

the scroll enclosure.

2. Appropriate expansion loops or bends should

be installed at the compressor to avoid stresses

caused by changes in hot and cold conditions.

3. Piping supports should be anchored separately

from the compressor to reduce noise and

vibration.

4. Never use any piping smaller than the compressor

outlet connection.

5. Use exible hose to connect the outlet of the

compressor to the piping so that the vibration of

the compressor does not transfer to the piping.

Safety Valves

Safety Valves must be installed on every receiver. The

ow capacity of a safety valve should be equal to or

greater than the capacity of the compressor.

1. The pressure setting of the safety valve must not

be greater than the maximum working pressure

of the air receiver.

2. Safety valves should be placed ahead of any

possible blockage point in the system, i.e. shuto

valve.

Loading...

Loading...