Scroll Enclosure Air Compressor 15-60 HP

Operating & Maintenance Manual

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN596202AV • 21 February 2023

Page 14 of 32

Alarm Signals

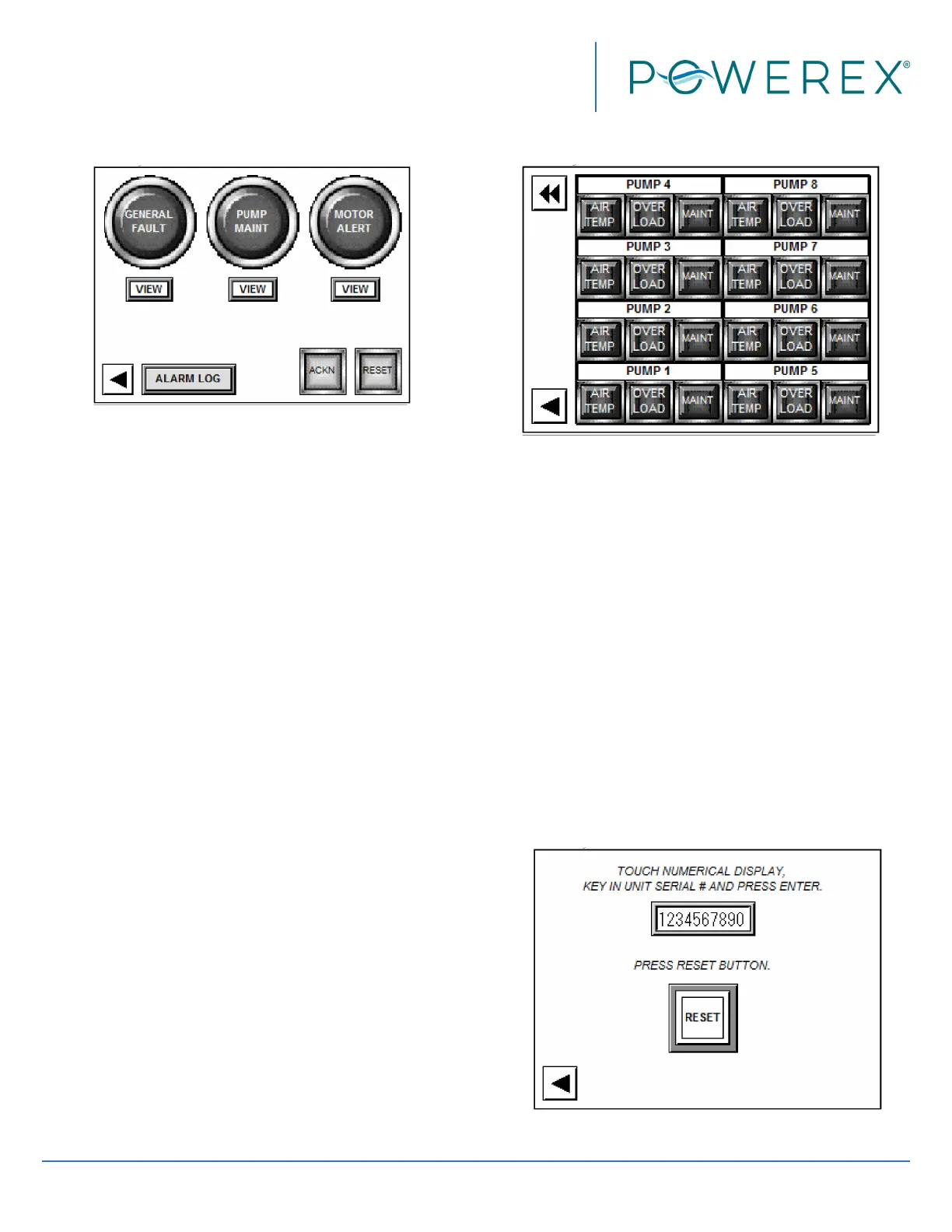

FIgure 14

The PLC control for the scroll enclosure compressor

will display the ALARM screen and activate the GENERAL

FAULT indicator on the alarm screen display if either of

the two conditions occurs:

1. High temperature at the sensor located at the after

cooler inlet. Each compressor module has its own

sensor. A high temperature condition will result

in the power to that motor being shut o. The

GENERAL FAULT alarm display will stay on and the

circuit will stay o even after the sensor cools, and

can only be restored when the alarm is cleared

by a user. If a high temperature condition occurs,

the reason should be determined and corrected

before restarting the circuit as unrepairable

damage to the scroll pump may result from

operation with repeated high temperature alarms.

2. Motor Overload, if the current to the motor

exceeds the setting of the adjustable motor

protector, the contactor associated with that

motor is de-energized, and that motor will not

run. The alarm display and condition is maintained

until the alarm is cleared and the motor protector

reset. The circuit will be restarted as needed. If a

motor overload occurs, the root cause should be

determined and corrected or motor damage may

result.

The user can activate the acknowledge function

(button labeled ACKN) to allow the display to go back to

SYSTEM STATUS or any other screen. Touch the VIEW

button to advance to a screen showing which pump-

motor assembly is in fault and for what reason. The

fault will display and the aected pump-motor will be

disabled until the RESET button is pushed.

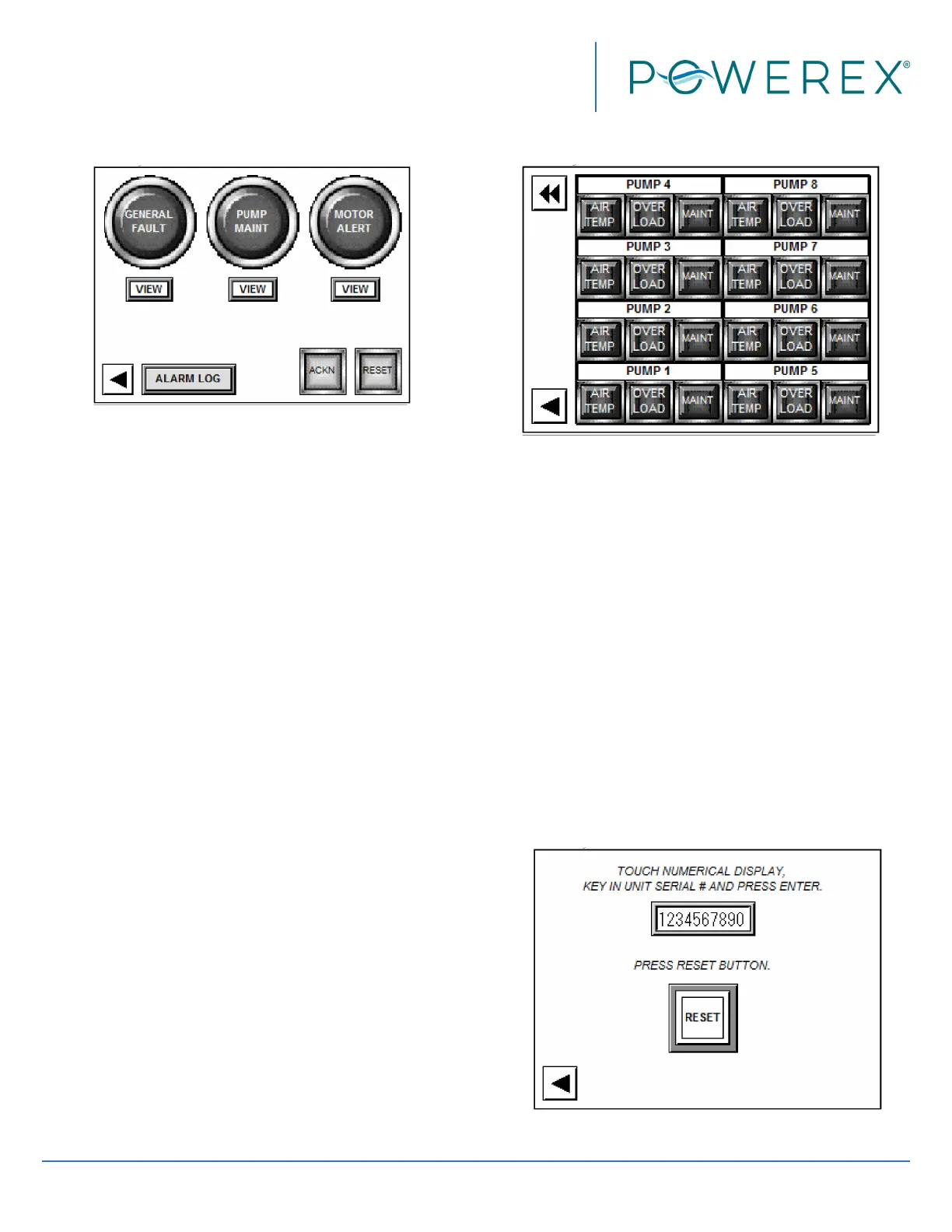

Figure 15

The PUMP MAINT indicator will activate when the

running hours of any pump accumulates to a required

maintenance interval. The system is designed for

multiple pumps to accu mulate hours evenly and for

maintenance intervals to be ap proached simultaneously.

To prevent nuisance PUMP MAINT indications, all

applicable maintenance counters should be reset after

the required maintenance actions are performed. Use

ACKN to allow the STATUS screen or other screens to

be displayed. Touch the VIEW button to advance to

the next screen. Consult the maintenance schedule on

page 15 and scroll air compressor manual for details of

what maintenance needs to be performed. To reset the

PUMP MAINT indicator for an individual pump, open the

PUMP INFO screen for that pump, hit the RESET button

and use the keypad display to enter the authorization

code when prompted.

Figure 16

Loading...

Loading...