Scroll Enclosure Air Compressor 15-60 HP

Operating & Maintenance Manual

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN596202AV • 21 February 2023

Page 5 of 32

Installation Site

1. The scroll compressor must be located in a clean,

well lit and well ventilated area. A contaminated

area can clog the intake lter and / or intake metal

mesh.

2. The area should be free of excessive dust, toxic

or ammable gases, moisture and direct sunlight.

3. Never install the compressor where the ambient

temperature is higher than 104°F or where

humidity is high. High humidity will cause electrical

short circuit and rusting of components.

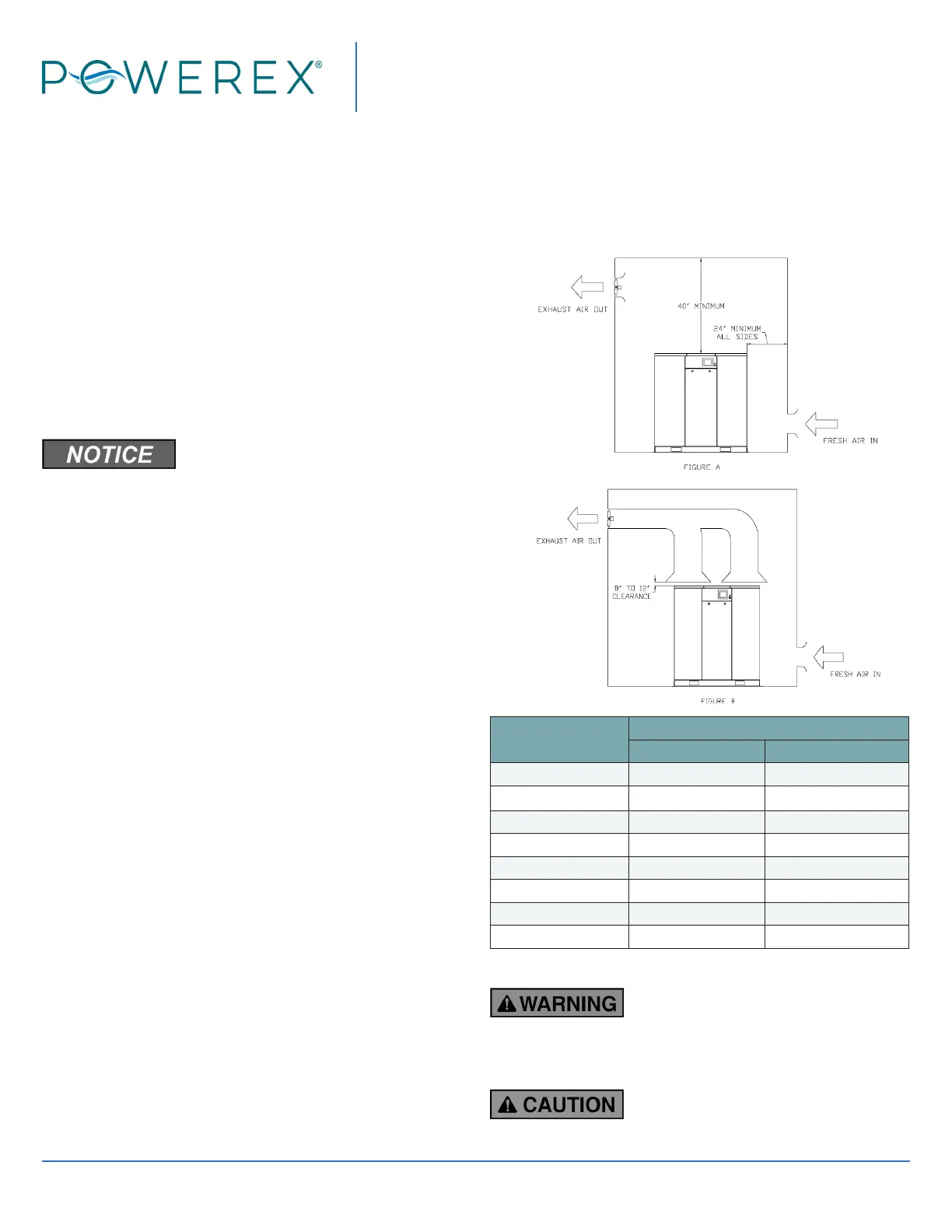

4. Clearance must allow for safe, eective inspection

and maintenance.

A minimum of 24 inches of clearance

for sides, 40 inch clearance from the top is required.

Consult OSHA and NEC for requirements on clearance

for electrical access. 36 inches or more may be required.

5. If necessary, use metal shims or leveling pads to

level the compressor. Never use wood to shim the

compressor.

Ventilation

1. If the scroll compressor is located in a totally

enclosed room, an exhaust fan with access to

outside air make up air must be installed.

2. Never restrict the cooling fan exhaust air or the

intake cooling air.

3. Vent the exhaust air outside to prevent the

compressor from operating at high temperatures

and shutting down.

4. Never locate the compressor where hot exhaust

air from other heat generating units may be pulled

into the unit.

Suggested Ventilation System

The temperature rise in the room must be kept

to a maximum of 10 F. The BTU capacity of the vent

system should be sized for the full operating HP rating

of the compressor. Suggested fan capacity at 0 static

pressure is shown below. If static pressure is higher,

the fan capacity should be increased.

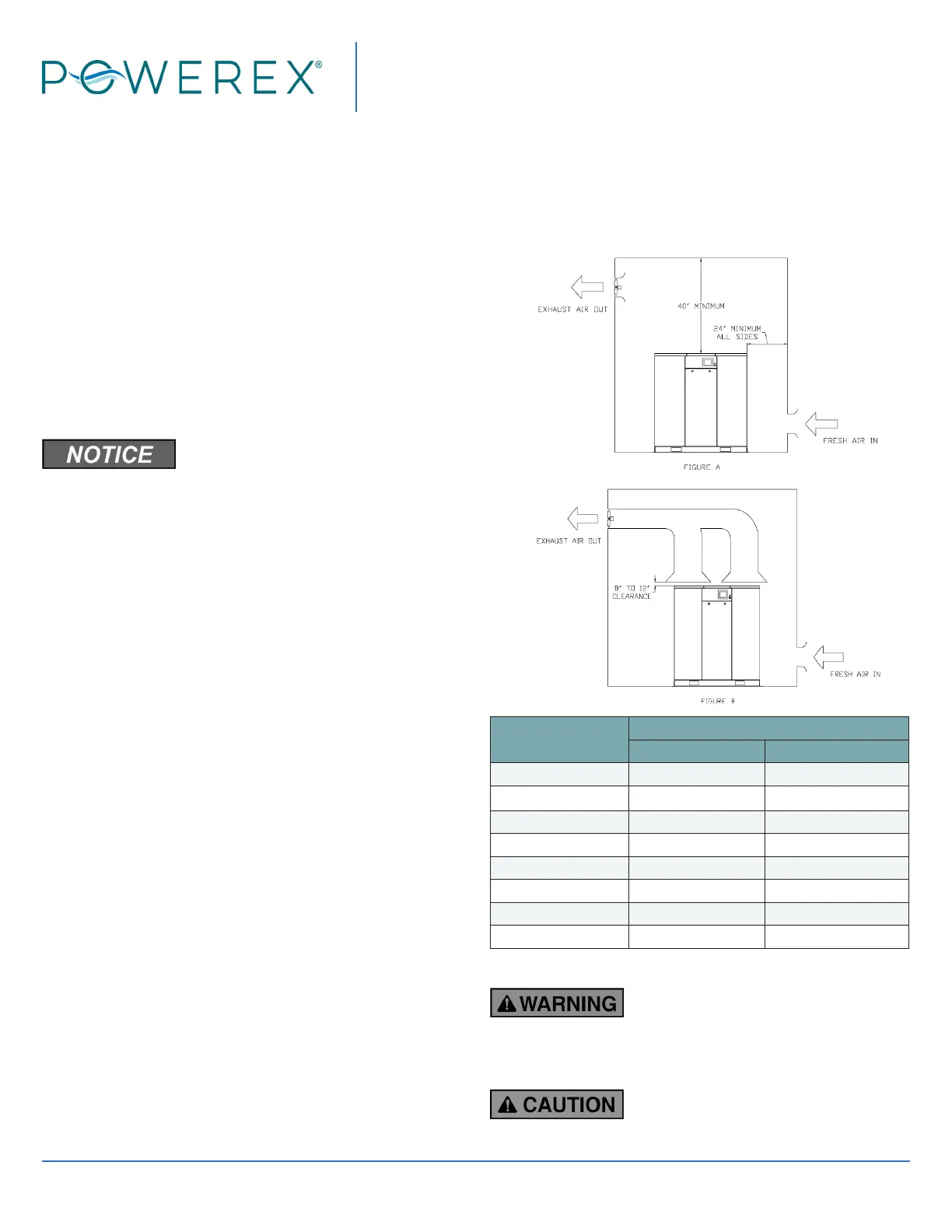

An exhaust duct may be installed to capture the warm

air exiting the compressor enclosure. The opening of

the exhaust duct should be about 6 inches larger on

each side than the vent openings on the compressor

top panel. The duct should not obstruct removal of the

top panel for service. Leave between 8 and 12 inches of

clearance. The CFM capacity of the exhaust fan should

be increased to compensate for duct ow losses.

Increase CFM if incoming air is above 85°F.

Total HP

Exhaust CFM Required

Figure A Figure B

15 5000 1700

20 6700 2200

22.5 7600 2500

30 10100 3400

40 13500 4500

45 15100 5000

50 16800 5600

60 20200 6700

Wiring

All wiring and electrical connections

must be performed by a qualied electrician.

Installations must be in accordance with local and

national codes.

Overheating, short circuiting and re

damage will result from inadequate wiring.

Loading...

Loading...