Scroll Enclosure Air Compressor 15-60 HP

Operating & Maintenance Manual

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN596202AV • 21 February 2023

Page 11 of 32

Start Up & Operation

1. Follow all the procedures under “Before start-up”

before attempting operation of the compressor.

2. Switch on the electric source.

3. Verify the display screen is lit.

4. If an isolation valve is installed between the

compressor unit and the air receiver, make sure it is

open. Close the isolation valve between the air receiver

and the facility piping.

5. Pushing the ON button beside the touch screen

will allow the unit to start and operate automatically.

Pushing the OFF button will stop the motors, but the

HMI screen will remain active.

6. If the pressure does not rise, turn the unit o, the

unit is running backwards. Have a qualied electrician

switch the breaker OFF and exchange two out of the

three phases of electrical source. If pressure is rising,

allow the compressor unit to run. Each compressor

motor will automatically turn o as the pressure rises

and the maximum operating pressure is reached.

Pressure settings may be adjusted as described below.

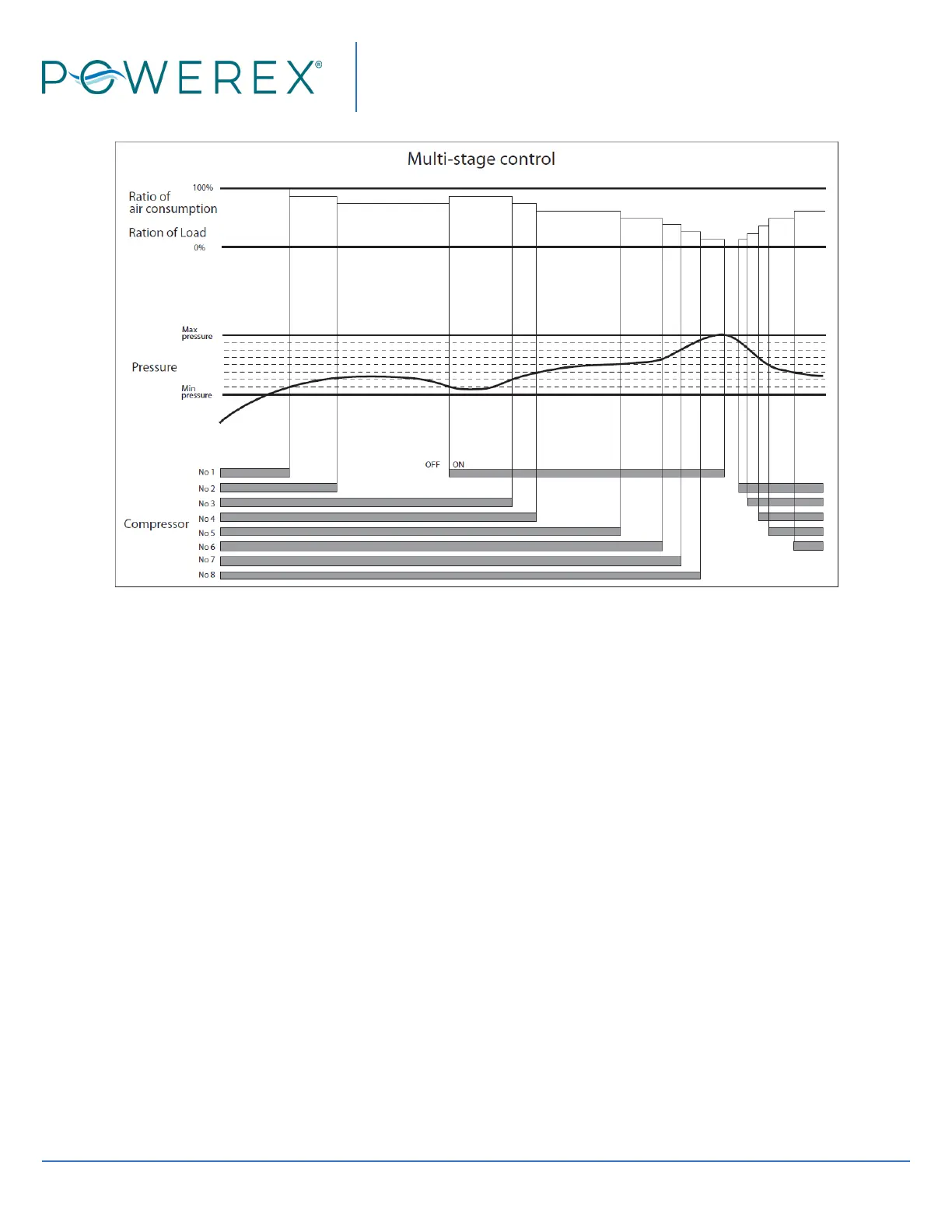

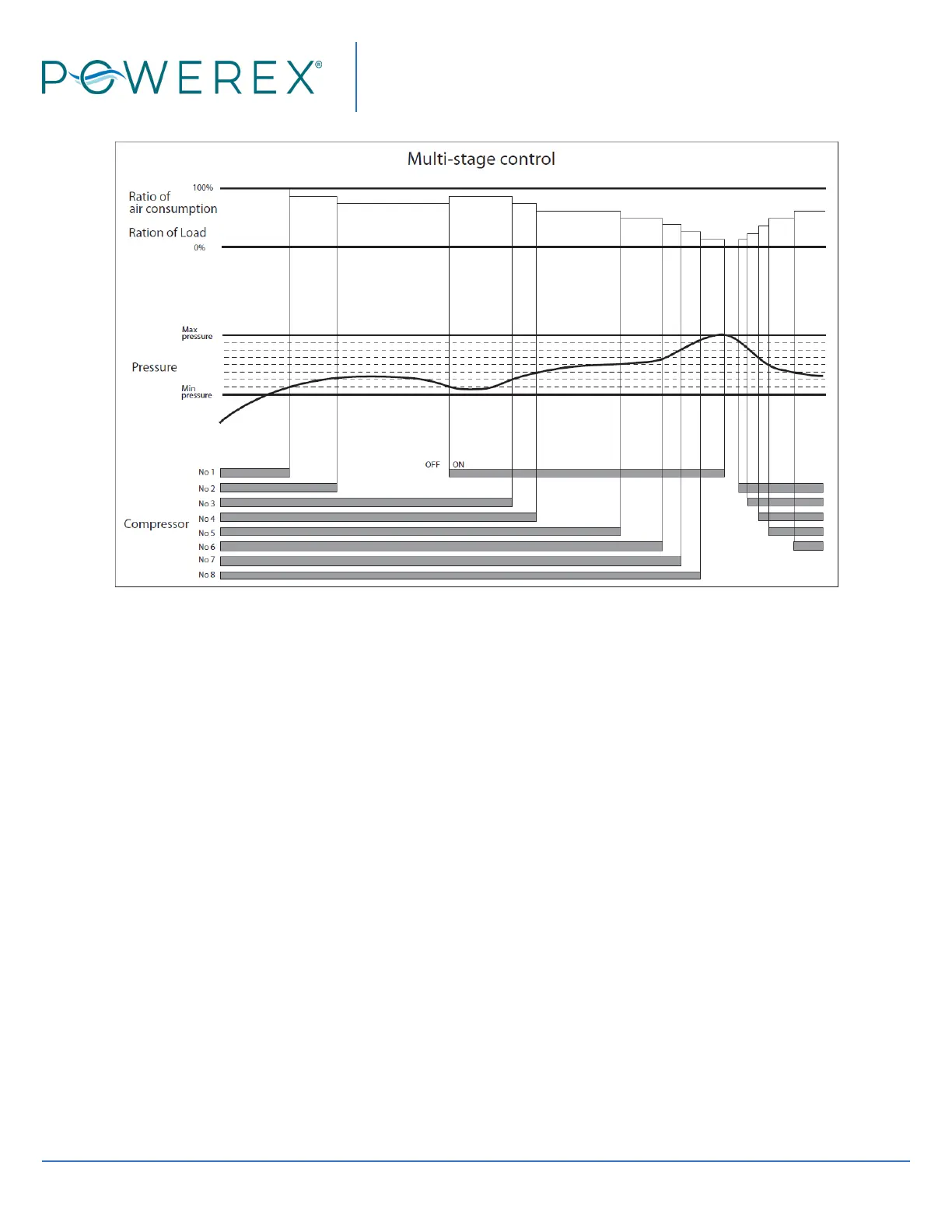

Table 3: The sequence is an example of operation of SEO4007. SEH3007 operate 6 air

7. Open the isolation valve between the air receiver

and the facility piping. The compressor will start and

stop each pump as needed to maintain the pressure

between the high and low set points.

8. After a few hours and again after a few days,

check the display screen to see if the ALARM screen

has appeared. If a HIGH TEMPERATURE or MOTOR

OVERLOAD condition occurs, the alarm screen will

appear and the aected pump-motor will be taken out of

service. If the chosen settings are causing the motors to

start too frequently, the ALARM screen will appear and

the MOTOR WARNING indicator will illuminate. Motor

warning will not take the motor out of service, but the

user should take action to prevent motor overload and

damage. To reduce motor starting frequency, adjust

the set points to a wider range between High and Low

and possibly increase the dierential. If starting is still

too frequent, a larger or additional air receiver will be

needed.

Shut Down

1. Stop the compressor by pushing the OFF button.

NOTE: If the compressor rotates in reverse for more than

ve seconds, the check valve needs to be cleaned or replaced.

Loading...

Loading...