Scroll Enclosure Air Compressor 15-60 HP

Operating & Maintenance Manual

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN596202AV • 21 February 2023

Page 8 of 32

if necessary. Some systems may be provided with the

isolation pads.

Condensation and Condensation Separators

The Powerex 7.5 and 10 HP Scroll Enclosed

compressor units include after coolers that will

generate condensation in the compressed air outlet

lines. Some models are shipped with condensate traps

for eld installation external to the enclosure and

systems will typically have condensate traps installed by

Powerex. Locate the condensate traps where they can

be conveniently accessed for maintenance. When an

isolation valve is used for a compressor unit, it may be

benecial to locate the trap on the compressor side so

the trap can be isolated with the unit for maintenance

and service.

Do not install check valves between

the compressor unit and the system air receiver. The

compressor pressure sensor must be in full connection

with the air receiver for the controls to operate properly.

Installation of a check valve will usually result in short

cycling the compressors and may damage the motors

and controls and reduce the compressor service life.

Do not modify the internal ow path

of the compressor unit. Do not modify the access

covers or latches. Improper modications may result

in risk of bursting, risk of injury and risk of equipment

damage. Do not operate the system with access covers

removed, as this will result in the risk of injury due to

access to internal moving or hot parts.

Do not modify the electric controls

or add any auxiliary loads to the electric system that

are not part of the original Powerex design. The main

power and control power circuits may be damaged by

unauthorized loads or modications resulting in a risk

of death or injury or equipment damage.

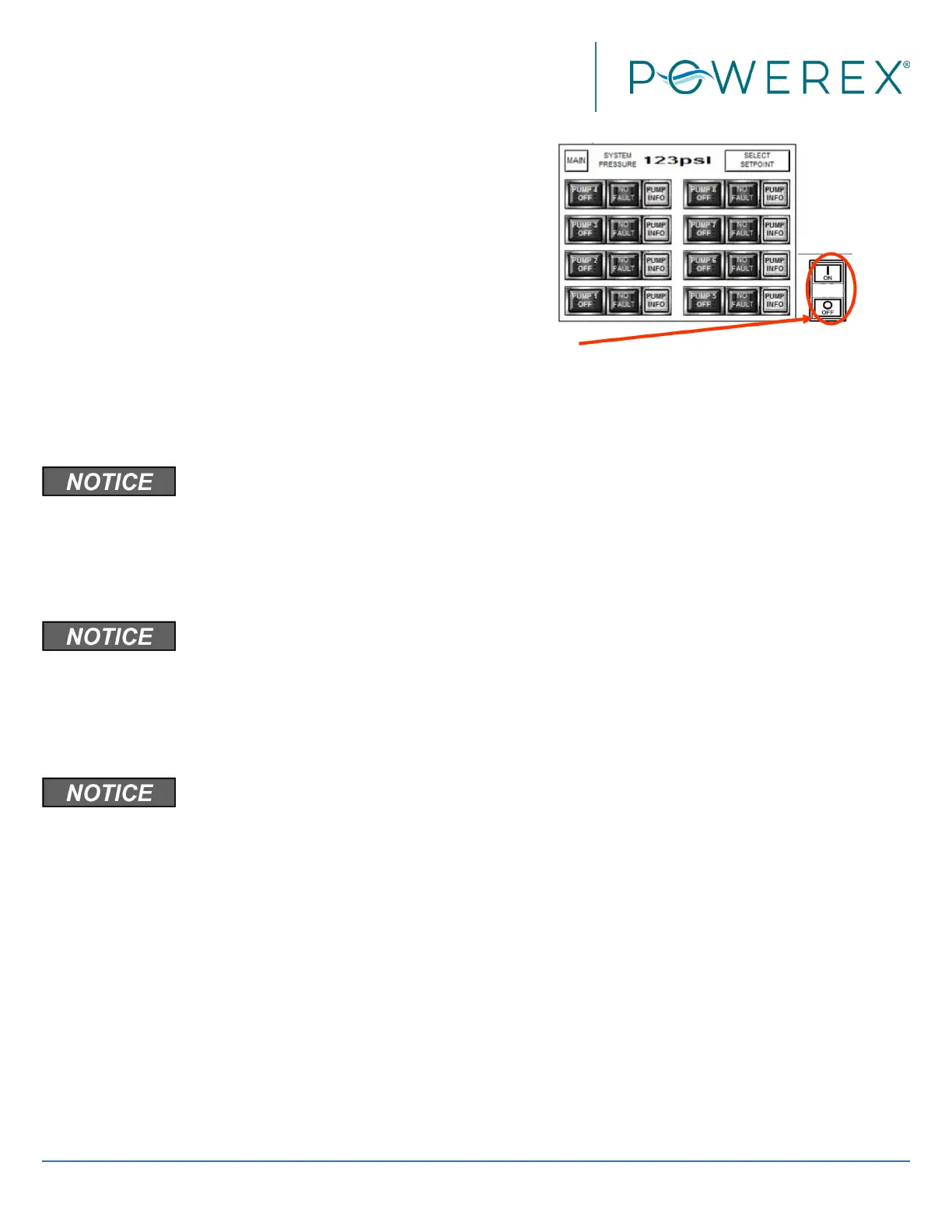

Control Panel – Display & Input

The Powerex scroll enclosure air compressor has a

power control switch and a touch screen or HMI panel

on the front to allow operation and monitoring of the

unit. See Controls section for details on operating the

unit using the touch screen.

The switch beside the screen controls power to the

motor starters. When the system is energized the HMI

screen will be lit and the control screen is active, but

the motors will not run until the ON button is pushed.

When ON is pushed, the center section of the switch

will illuminate, enabling the PLC control of the system,

and will remain lit until the OFF button is pushed. The

OFF button on the switch may be used to stop the

compressors at any time. The switch does not turn o

power to the panel so be sure to lock out the power

source before opening the panel for service.

NOTE: The “Jog” function on the screen overrides the

ON switch. The motors will operate if the Jog button

is continually depressed. To reach “JOG” press the

SYSTEM STATUS button, then press PUMP INFO for the

pump module you want to jog.

The PUMP INFO screen is shown below. Press the >

arrow button to jog pumps.

Loading...

Loading...