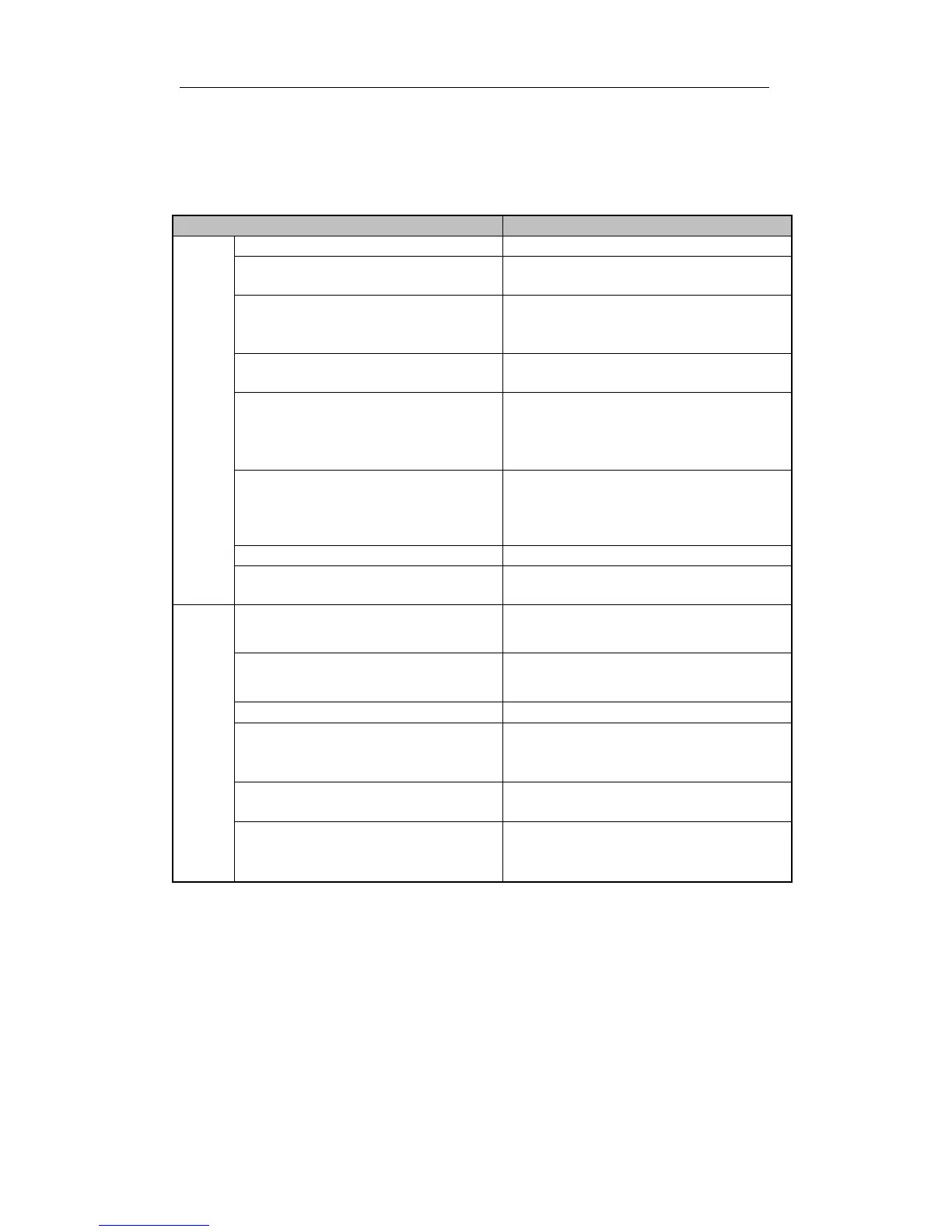

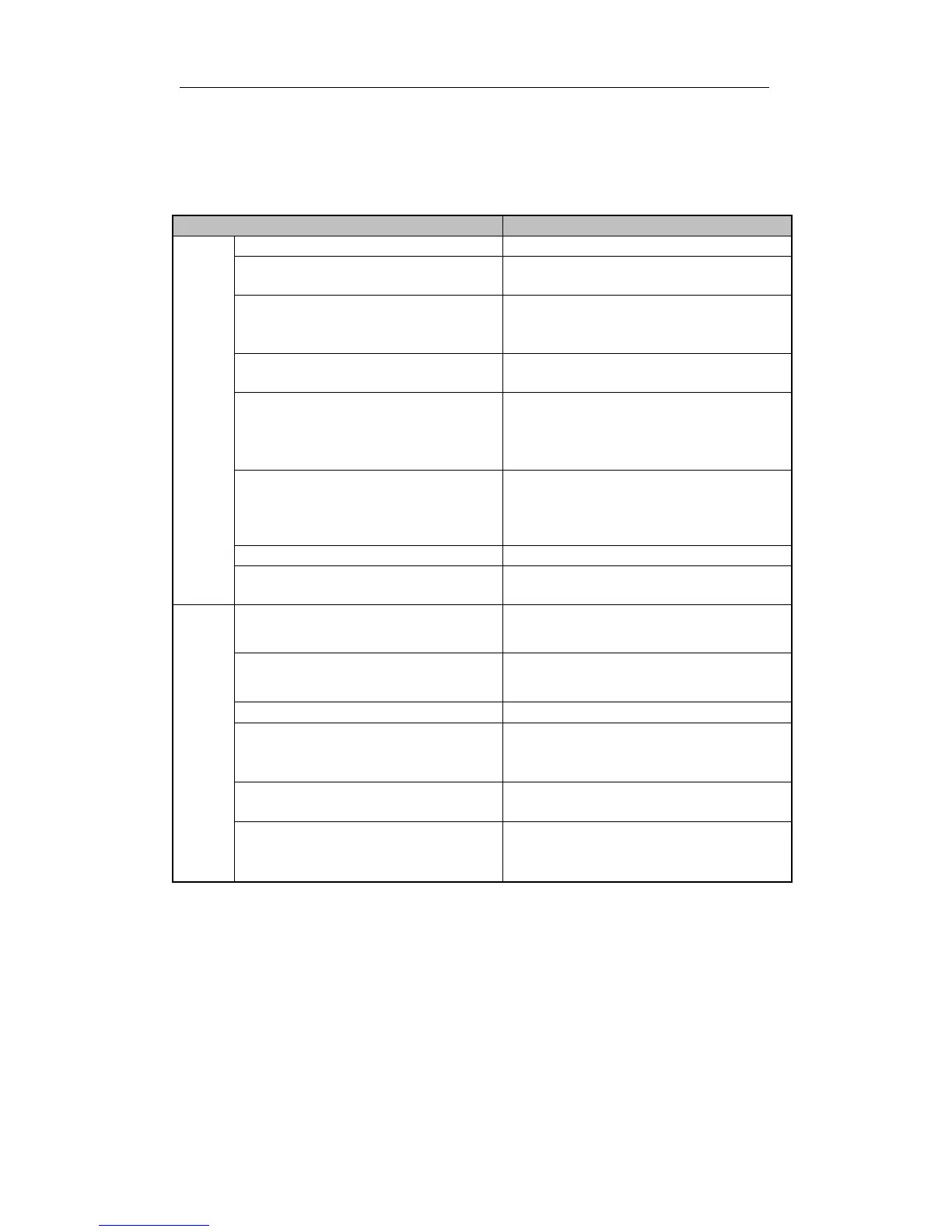

TROUBLESHOOTING

CHAPTER 4 TROUBLESHOOTING

4-1 Troubleshooting procedures

Diesel cannot be started.

The switch of fuel is not at

“OPEN” position.

Turn the switch of fuel to “OPEN”

position.

High-pressure pump and nozzle

do not inject fuel or the injected

amount is less.

Disassemble the nozzle and adjust it

at test table.

Speed control lever is not at

“RUN” position.

Turn speed control lever to “RUN”

position.

Check level of lubrication oil.

The standard oil amount of

lubricating oil should be between

high graduation “H” and low

graduation “L”.

It is not quick and powerful to pull

reactive starter.

Start diesel engine in accordance

with the requirements of “start

operation procedures”.

Accumulator has not electricity.

Charge the accumulator or

exchange it.

Generator cannot generate electricity

and has not welding voltage

Master switch (NFB) is not be

switched on.

Turn master switch handle to “ON”

position.

Carbon brush of generator was

worn. The contact is bad.

Exchange the carbon brush.

The contact of socket is bad.

Adjust the contact feet of socket.

The rated revolution of engine

cannot be reached.

Make it reach to the rated revolution

in accordance with the

requirements.

AVR automatic governor is

damaged.

The potentiometer of current

regulation for electric welding is

damaged.

If you are still having trouble, please contact with your nearest dealer or with

our company directly if necessary.

4-2 Questions and doubts

1. Model of diesel engine generator and engine model number.

2. State of residency.

3. Number of hours of operating equipment along with the problem that occurred.

4. A detailed condition and time when the problem occurred, in other words,

climate and atmosphere.

Loading...

Loading...