Model

1000

Installation and Operation Manual

Page

13

OFFICIAL 6/1/2001

H

OW

D

O

I …

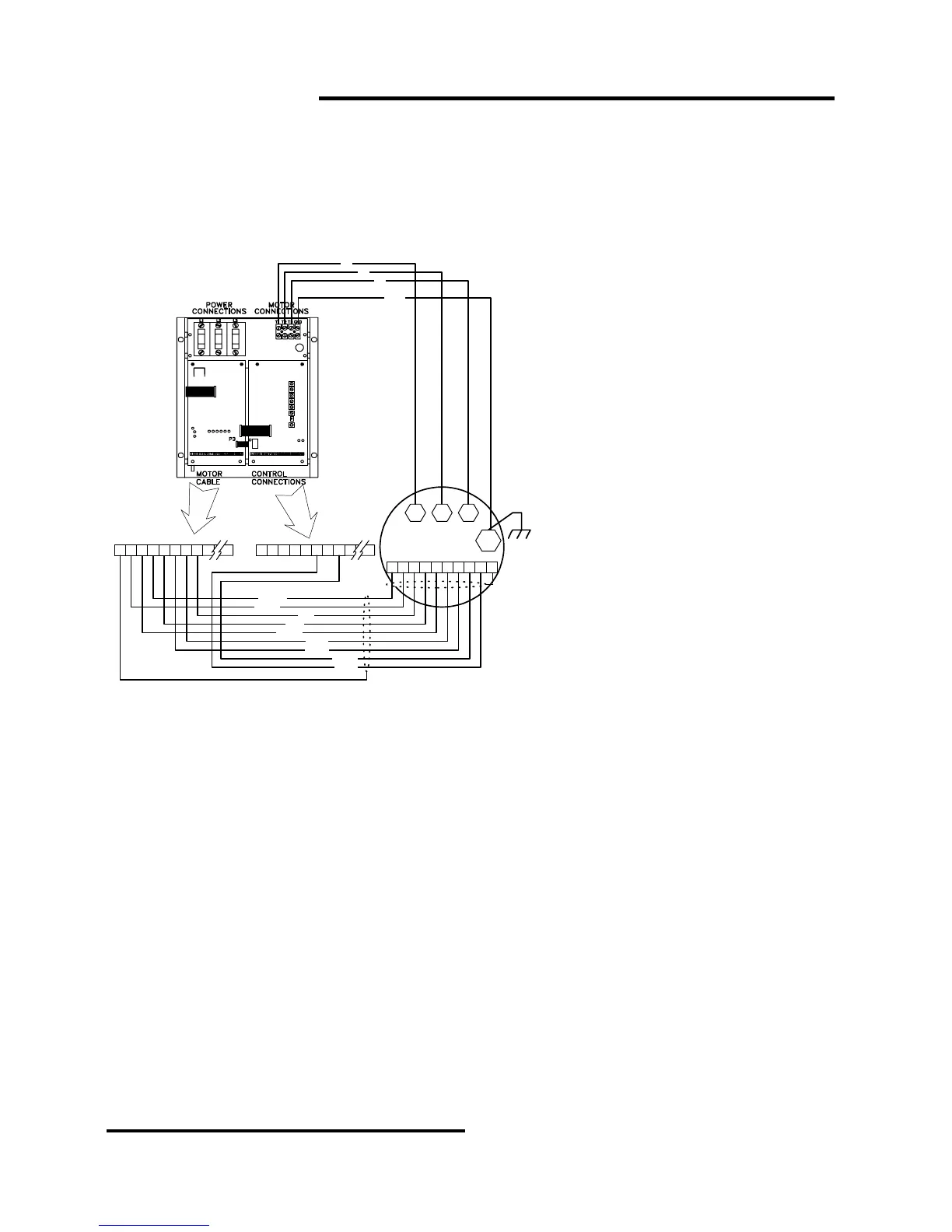

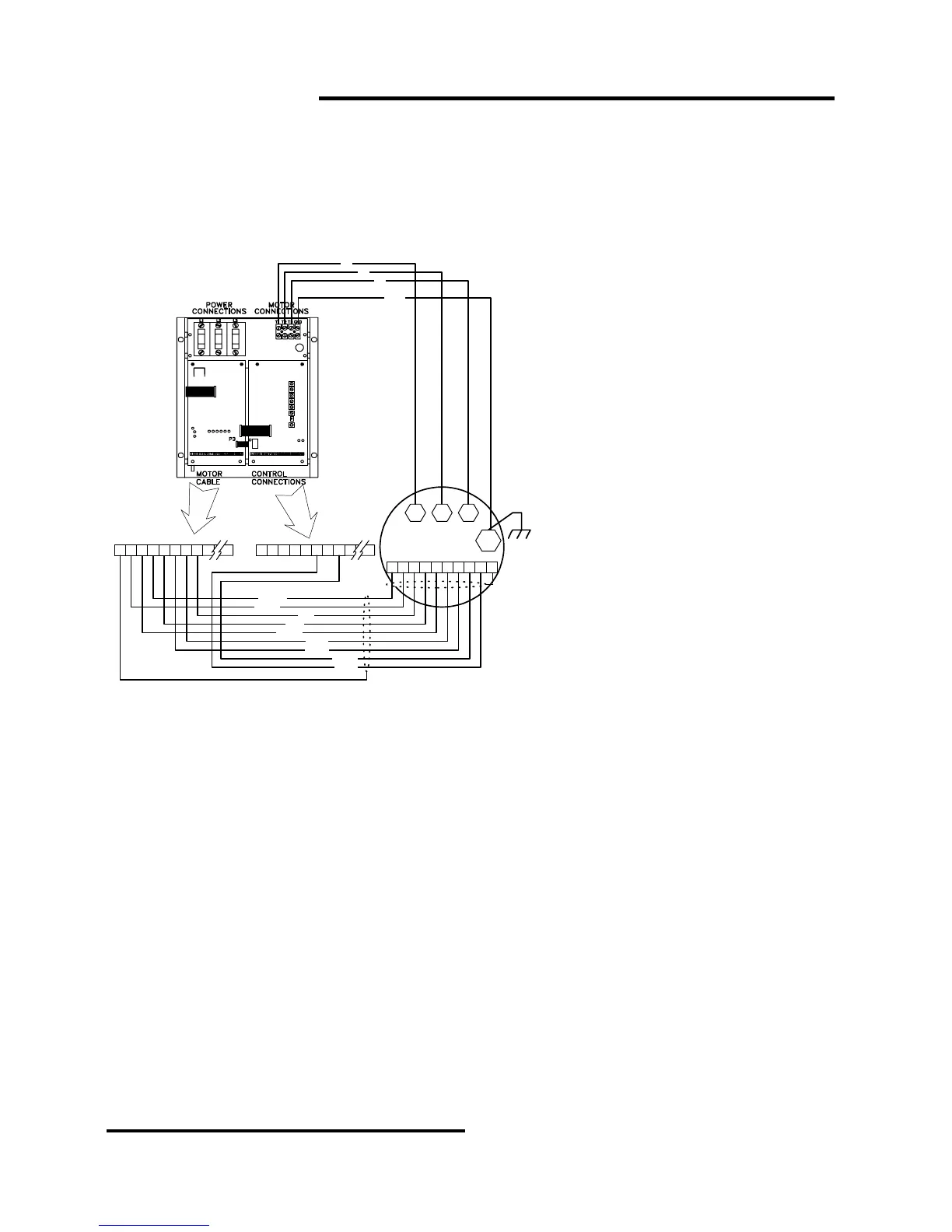

CONNECT THE MOTOR TO THE 1000 DRIVE?

We ship every drive from the factory with A STANDARD CONNECTIONS card.

Connect the motor lead marked T1 to the

T1 terminal on the drive. Connect the T2 lead

to T2 on the drive, and connect T3 to T3.

Other connections to T1, T2, and T3 at the

motor will vary with the motor. The motor will

not operate correctly if the power wires from

motor to drive are not in the proper order.

Full load motor current determines the

wire size to the motor. The table on the

opposite page lists these currents.

Any high voltage, high frequency

equipment generates EMI and RFI.

YOU

MUST USE METALLIC CONDUIT TO

ENCLOSE MOTOR WIRES

BETWEEN THE

MOTOR AND THE DRIVE.

This will minimize

interference.

You must install a ground wire between

the motor frame and the drive chassis. There

is a ground lug in most motors. If there is no

ground lug, make a connection at any bolt in

the motor junction box.

THIS GROUND WIRE MUST BE RUN IN

ADDITION TO GROUNDING THE MOTOR FRAME TO ITS MOUNTING, WHICH IS REQUIRED BY

CODE.

The purpose of this separate ground is to equalize the potential between the motor's frame and the drive

chassis. There may be enough impedance to broadcast EMI and RFI even with the motor grounded to its

mounting frame. A direct wire connection between the motor frame and the drive chassis minimizes

interference in other equipment.

The encoder feedback cable must be a shielded cable. Connect the shield to TB1 terminal 1 on the

control end. Standard installation requires a nine-conductor shielded cable (Belden

™

part #9539 or equivalent).

The colors of this cable correspond to the colors of the wires in the motor and on the connection diagram. You

may interchange the Purple and White wires without ill effect.

The shield must be continuous from the motor to the control. Do NOT ground the shield at intermediate

points. This applies to all junction boxes installed between motor and control.

DO NOT USE THE SHIELD OF THE ENCODER CABLE AS AN ACTIVE CONDUCTOR!

If you want to use the motor thermal protector in a 120 VAC circuit, run it in wiring separate from the

cable. Use seven-conductor shielded cable. In this case, if the cable wire colors are different from the

diagram, you need to check them carefully for proper connections.

BLDC

MOTOR

T1 T2 T3

GND

1 2 3 4 5 6 7 8 9 S

T1

T2

T3

GND

Blue

Brown

Black

Orange

Red

Green

Yellow

16

1 2 3 4 5 6 7 89

TB1

18

1 2 3 4 5 6 7 89

TB2

Purple

White

SEE FUSE

INPUT

BOARD

DRAWING

ON PAGE 8

SEE MOTOR

MANUAL FOR

CORRECT

MOTOR

CONNECTIONS

Loading...

Loading...