page no. 32 of 68

LX Range Users, Installation & Servicing Instructions Doc Ref M110 issue 1.0 Dec 2020.

6. Apply a bead of silicon sealant around the face of the

flange on the exhaust fan outlet tube that can be seen

from the outside of the heater. Place the flue socket on

the outside of the heater to mate with this flange and

clamp the two flanges together, on either side of the

heater panel using the screws provided. Ensure that the

silicon sealant has sealed between the two flanges.

7. Apply silicon sealant and refit blanking plates as

required to seal unused panel holes.

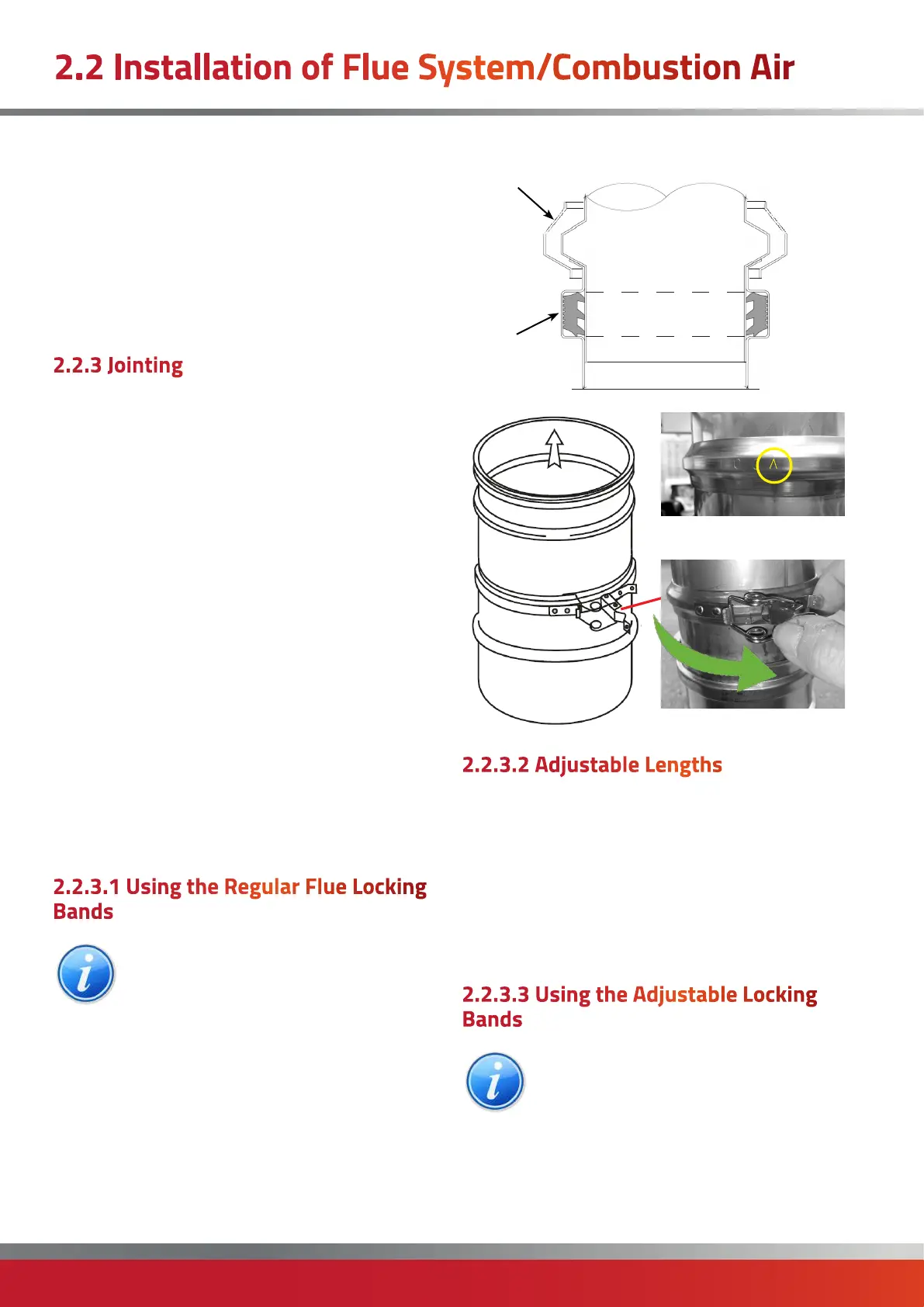

2.2.3 Jointing

The flue system is jointed by pushing the male end into

the female end of the proceeding component, and then

applying a Locking Band.

Each flue item comes complete with a factory bonded

elastomer seal which provides a secure grip to the male

end of the next flue component.

A seal lubricant gel can be used to facilitate ease of

installation and prevent potential damage of the seal

during installation

If shorter lengths of flue are required then Powrmatic

supply an adjustable length which provides adjustment

between 75-230mm.

In extreme circumstances, and where an adjustable

length cannot be used, flue may be cut but only the male

end should be removed to retain the flue seal. The cut end

must be clean and free from burrs before fitting into the

seal ring of the female end. As the locking band cannot

be used, we would suggest fixing the joint by a ring of

sealant and fixed using three self tapping screws, being

careful not to pierce the inner seal ring

2.2.3.1 Using the Regular Flue Locking

Bands

NOTE: The locking band has a defined profile

which will only allow for the toggle to be

closed one way. An indication arrow marked on

the face of the clamp must be pointing

towards the inserted male end.

Therefore when assembling the band onto the flue, the

toggle must snap to the right (see following diagram).

Cross sectional area detailing sealing arrangement.

Female socket

Male end

Seal

Ring

Locking

Band

Female end

Male end

Toggle must snap to the right

Arrow MUST be pointing

towards the inserted male

end of the flue

Female end

Male end

2.2.3.2 Adjustable Lengths

The Adjustable Length consists of a slip section of flue, the

lower non-beaded end of which is designed preferably to

be located into a standard length. It can also be inserted

into the female end of other components, but however

applied, must engage to a depth equivalent to at least half

of the diameter of the flue being used. Adjustment from

75mm to 230mm. Where pressure and moisture resistance

are required a special Locking Band & Seal is required to

make the joint.

2.2.3.3 Using the Adjustable Locking

Bands

NOTE: The locking band has a defined profile

which will only allow for the toggle to be

closed one way. An indication arrow marked on

the face of the clamp must be pointing

towards the inserted male end.

Therefore when assembling the band onto the flue, the

toggle must snap to the right (see following diagram).

2.2 Installation of Flue System/Combustion Air

Loading...

Loading...