Section VI. Function Parameter Description

Motor’s output frequency under rated state.

b00~b04 are the motor’s nameplate parameters which touch the

precision.Set the parameters according to the motor’s nameplate.

Excellent vector control performance requires exact motor parameters.

Exact parameters are base on the correct setting of motor’s rated

parameters.

To assure the control performance, please match the right motor as per the

inverter’s standard, motor rated currentis limited between 30%~120% of

inverter rated current.

b05: motor un-load current factory setting: (y07×40%)A

The un-load current, and affects the degree of the slip compensation

directly.

The factory value is decided by power and default value is y07×40%.

b06: stator resistor factory setting: 0.000ohm

The stator resistor, when b13 is 1,the system scales automatically.

b07: rotor resistor factory setting: 0.000ohm

The rotor resistor, when b13 is 1, the system scales automatically.

b08: leakage inductance factory setting: 0.0mH

The leakage inductance of motor’s coil winding, when b13=1, system

measures automatically.

b09: mutual inductance factory setting: 0.0mH

The mutual inductance of motor’s coil winding, when b13=1, system

measures automatically.

b05~b09 is the motor’s basic electric parameters, these parameters is

essential to achieve vector control calculation.

When b01 is set, b05~b09 would automatically reset to the defaulted

standard Y series 4 poles asynchronism motor’s parameters. Inverter could

get the motor parameters without automatic parameters setting.

If the inverter could not meet with the requirement, use b13 motor

parameters setting to get the exact motor parameter. If the right motor

parameters are available, it could be input manually.

*b10~b13: Reserved

b14: Rotate speed display plus factory setting: 100.0%

Adjust the display of motor’s actual running speed, refer to F00 monitor

select: 6 Actual motor speed.

b15: Reserved factory setting: 0

b16: Reserved factory setting: 0

b17: Reserved factory setting: 0

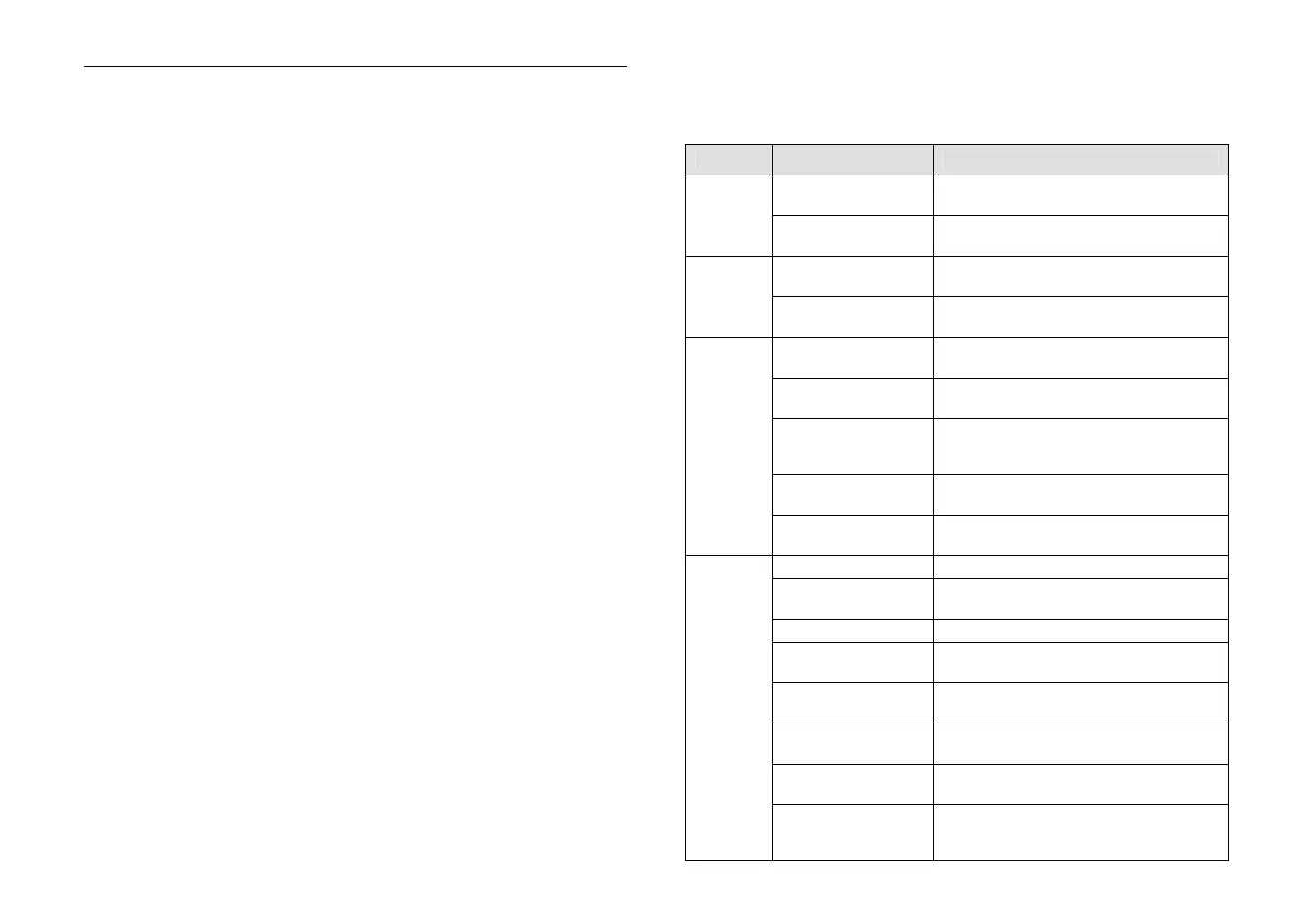

Section VII. Fault Diagnosis and Solutions

Problems

Possible causes Solutions

Control mode setting is

wrong

Check F05.

not control

Frequency setting is

wrong

Check F04.

Control mode setting is

wrong

Check F05.

speed

Frequency setting is

wrong

Check F04.

LED monitor indicates

error message

No voltage exists between

terminals P and N.

Check the voltage at R,S or T and charging

circuit.

U, V or W terminals

produce no output or

abnormal output.

Check the control mode and frequency

parameter. Check the terminal condition if it is

operated by an external terminal.

Re-start after powering

down or free run

Remember the set operating state.

The

motor

does

not

rotate

Too much load on the

motor

Check and lower the load.

fault display OC-P System is disturbed or instant over current

fault display OC-C

OC signal from current self-inspected citcuit

impact

fault display OC-FA OC signal from drive circuit

fault display OC-2

Output over current, and current exceed 2 times

of motor’s rated current.

Over current during

acceleration

Reset or modify the parameters of the functions

F09, F18, F19.

Over current during

deceleration

Reset or modify the parameters of the functions

F10, F20, F21.

Over current during

operation

Check the load change and eliminate it.

Over current

OC

Over current during

starting or operation from

time to time

Check if there is slight short circuit or grounding.

Loading...

Loading...