27

Copyright © 2020 Quality Machine Tools, LLCPM-1440GT v9 2020-10

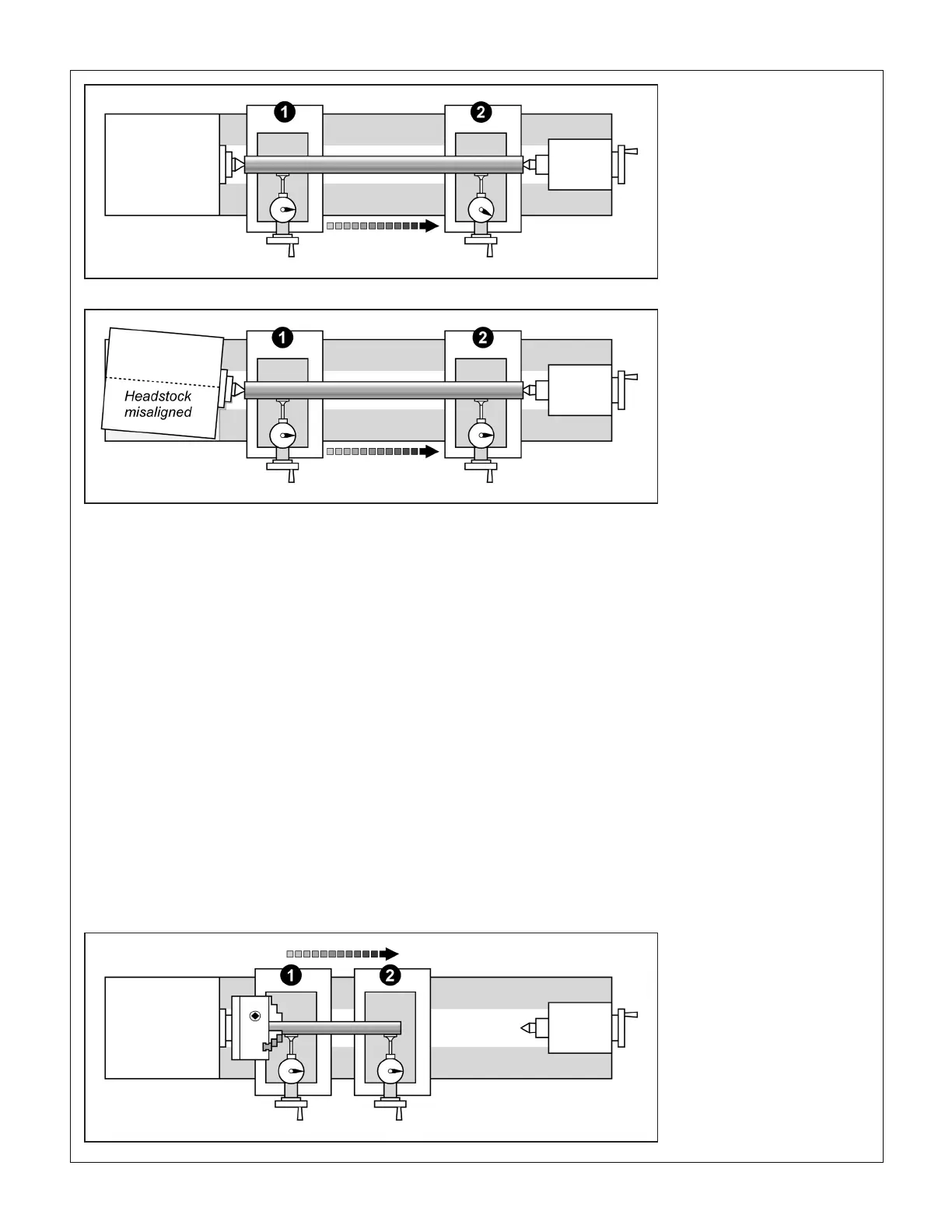

Figure C Drill rod between

centers

Figure D Misalignment of the

center turning

by as little as 0.002”, a tiny amount even if jacking screws are

provided. What this amounts to is that headstock adjustment

is a highly sensitive, iterative procedure that should not be

attempted casually. What follows is a general outline. Specic

instructions for the PM-1440GT follow this section.

HEADSTOCK ALIGNMENT METHODS

Method 1

Make a series of "cut-and-try" passes on scrap material. If the

workpiece is thinner at the tailstock end, the headstock needs

to be pivoted away from the tool, and vice versa.

Method 2

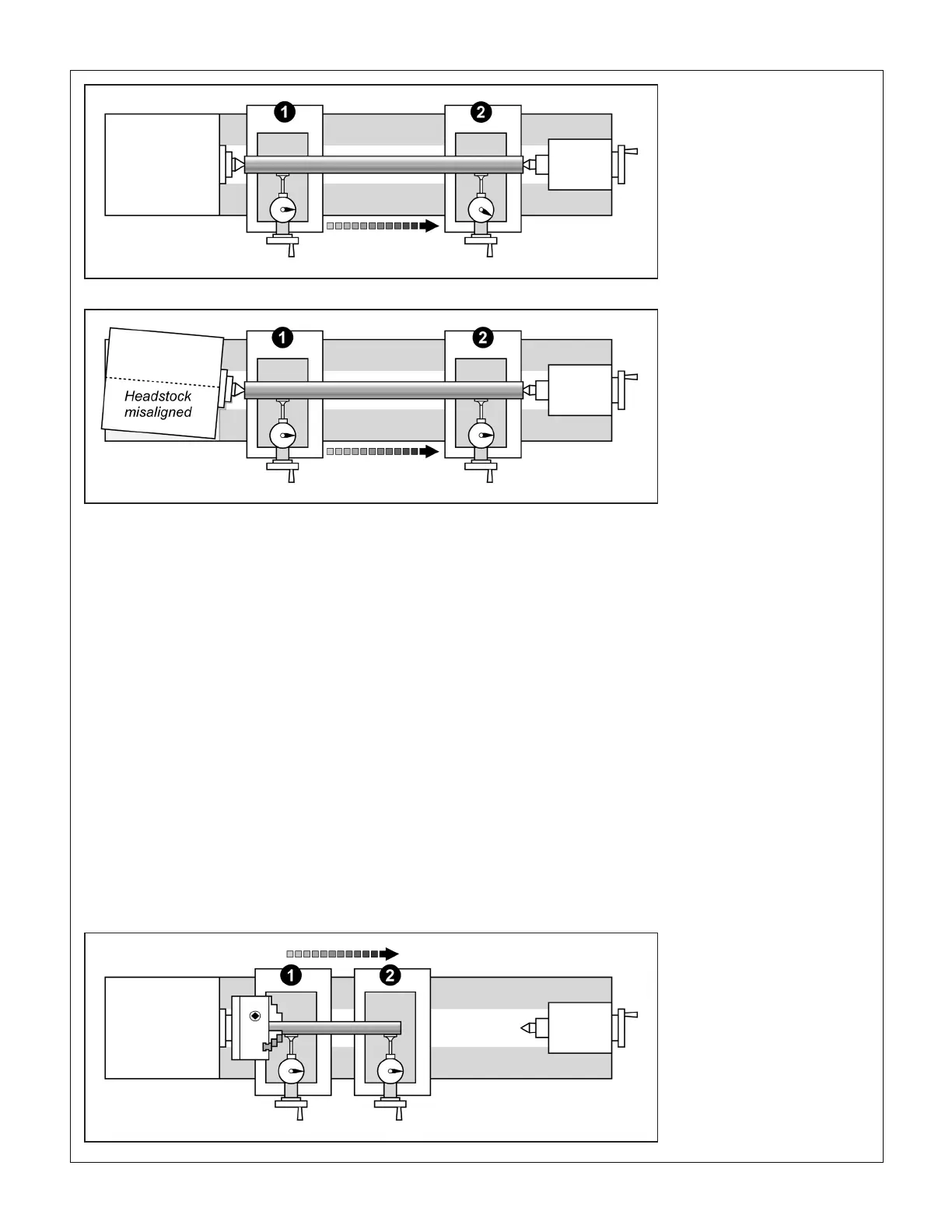

This uses the 3/4 or 1 inch ground drill rod described in "Pre-

cise method" above for center-to-center alignment.

Install the drill rod in a collet or independent 4-jaw chuck with

about 5 inches protruding, Figure E. Center drilling is not need-

ed.

1. Adjust the chuck for minimum runout at position (1).

2. Check the runout at (2). Pointer movement when traversing

is not a concern at this stage.

3. If the drill rod is perfectly aligned with the spindle axis, there

should be no dierence in TIR at (1) and (2).

4. If there is a signicant dierence in TIR* from (1) to (2), try

to correct this by loosening, then re-tightening the chuck/

collet, while levering the outer end of the rod (gentle tap-

ping with a non-marring hammer can also be helpful).

When the runout at (2) has been minimized, re-check at

(1), then repeat at (2), etc.

5. When (and only when) the TIR at both locations is the

same, or very close, can it be said that the rod is concentric

with the spindle.

6. Compare dial indications when traversing from (1) to (2).

Ideally, there will no change.

Figure E Perfect alignment:

zero indicator change be-

tween locations 1 and 2

* Factors that may aect runout

Straightness and roundness of the drill rod; Chuck installation

(check for cleanliness and tightness); "Pointing accuracy" of the

chuck (the gripping surfaces of chuck jaws may not be parallel

with the axis of the chuck and spindle — especially likely if the

chuck is worn).

Loading...

Loading...