28

Copyright © 2020 Quality Machine Tools, LLCPM-1440GT v9 2020-10

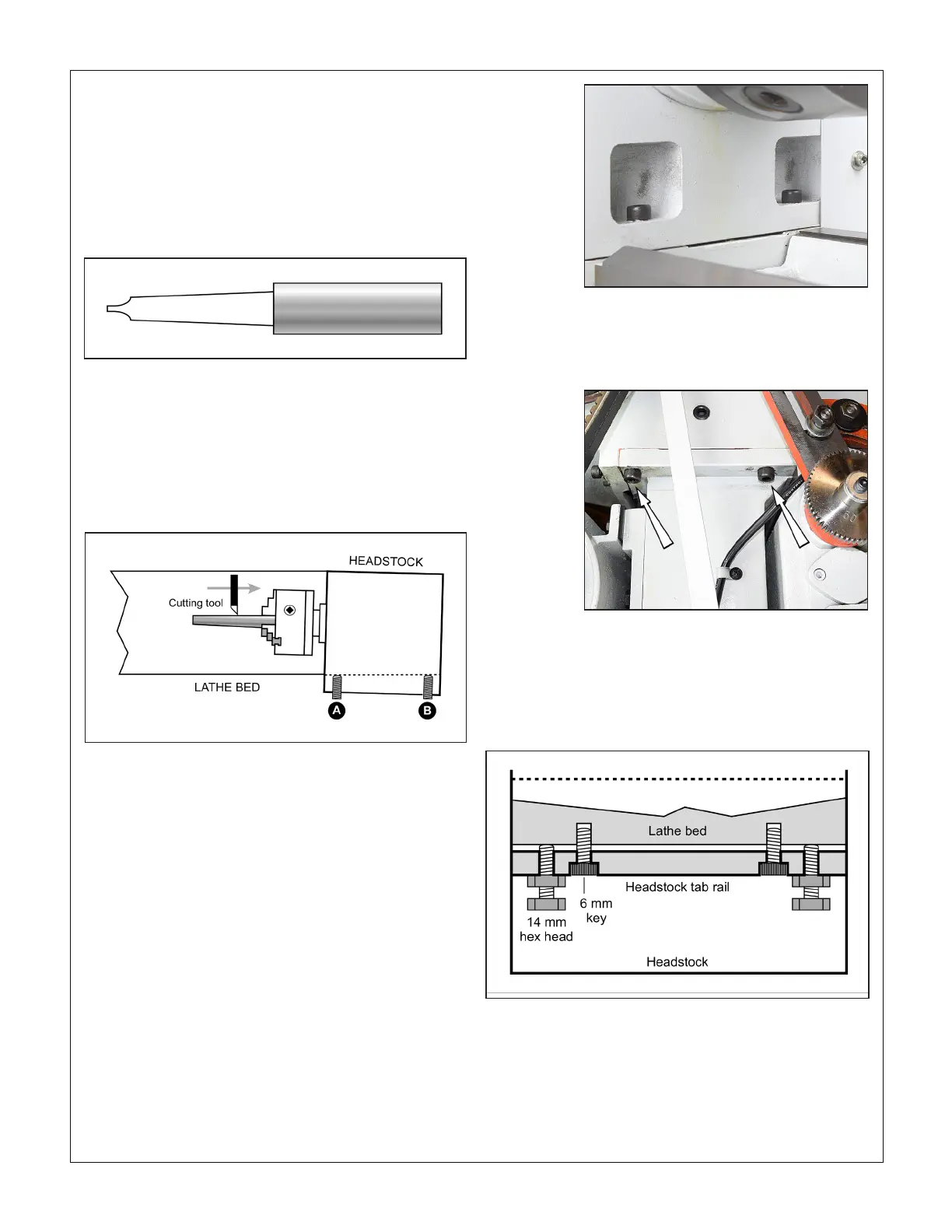

Figure F Morse taper test bar

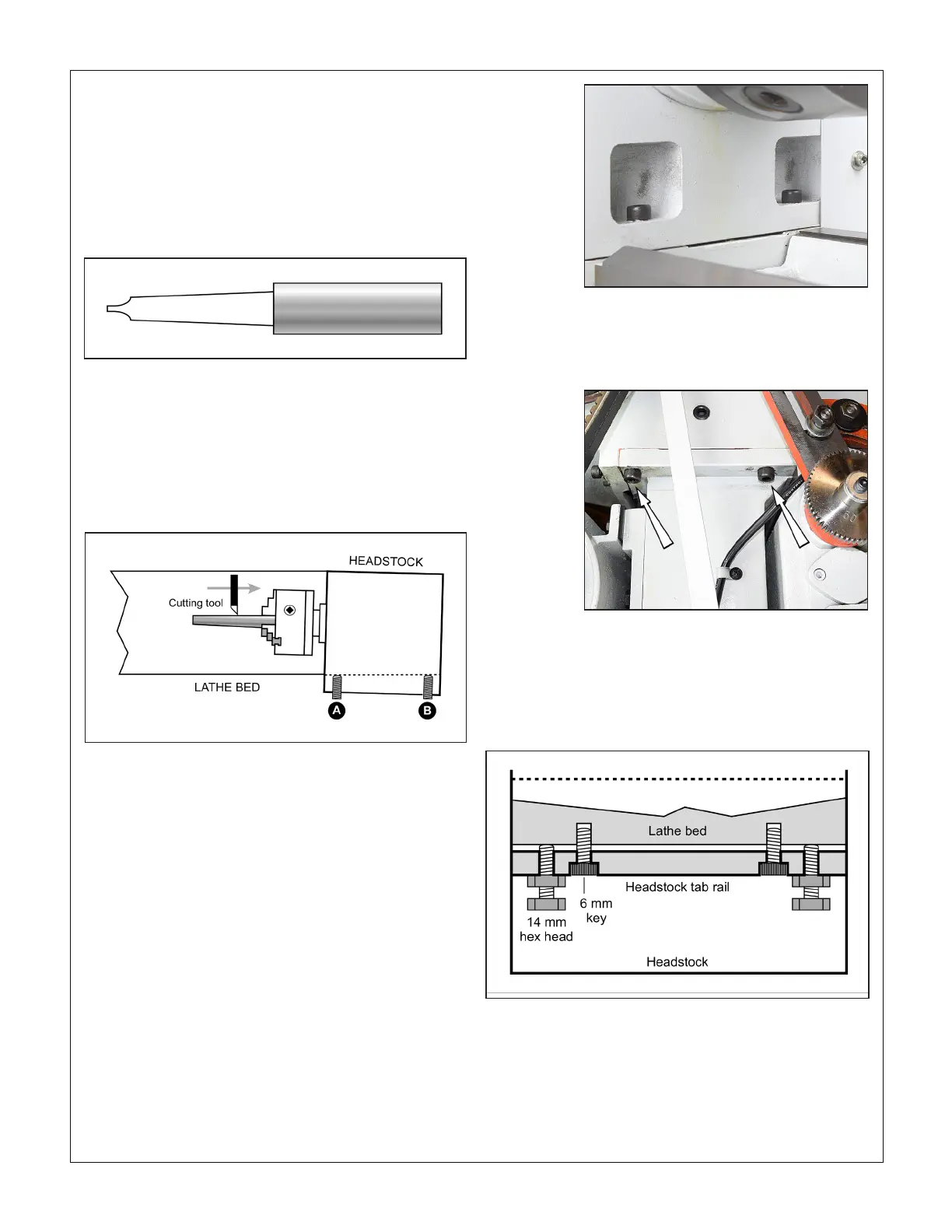

PM-1440GT HEADSTOCK ALIGNMENT

Figure A1 is an exaggerated top-down view of what happens

if the spindle is not precisely aligned with the lathe bed. This

is correctable by slightly loosening the attachment screws,

Figures A2 and A3, then adjusting the screws set into a tab rail

below the headstock, Figure A4.

CAUTION!

Correcting headstock misalignment is a multi-step process re-

quiring a number of extremely small adjustments, each one

followed by an alignment test, either cut-and-try, or one of the

other methods previously described.

A scarcely detectable rotation of an adjusting screw can

be the dierence between perfect alignment and unac-

ceptable taper. In other words, think in terms of thousandths

of an inch or less. Simply loosening the socket heads, Figure

A4, can be enough to correct a taper problem — or add to it in

the wrong direction.

Figure A3 Misaligned headstock

In this illustration the workpiece diameter increases as the cut-

ting tool moves toward the chuck. Correct this by screwing in

(A) a fraction of a turn to rotate the headstock counter clock-

wise, moving the workpiece away from the tool. Screw in (B)

if the taper is in the other direction, thinner toward the chuck.

Figure A4 Adjustment screws below the headstock

The recessed socket head screws lock the adjustment by pull-

ing the tab rail toward the lathe bed. Loosen the socket heads

a fraction before touching the hex heads.

Figure A3 Headstock attachment screws, LH

Figure A2 Headstock attachment screws, RH

Method 3 - Morse Taper Test Bar

This is a catalog-only item available from many suppliers (de-

pending on the source it may be named dierently). The test

bar in Figure F has a tapered shank to t the spindle, and a

parallel portion several inches long. The diameter of the paral-

lel portion is unimportant. What matters more is its nish and

lack of taper— check before installing. Whatever taper there

may be can be allowed for in the alignment test, as Figure E.

Runout should be less than 0.0005" TIR.

Loading...

Loading...