20

PM-833TV 4-13-21V1.indd Copyright © 2021 Quality Machine Tools, LLC

Section 4 MAINTENANCE

Disconnect 220V power before any

maintenance operation!

RECOMMENDED LUBRICANTS

One-shot lube system: ISO 68 oil, such as Mobil Vac-

tra No. 2, or equivalent

X, Y and Z axis ways (dovetails): ISO 68 oil, Mobil

Vactra No. 2, or equivalent

Visible gears such as quill rack and pinion, Z-axis

bevel gears: light general purpose grease, NLGI No. 2,

or equivalent

X and Y leadscrews: ISO 68 oil, Vactra No. 2 or equiv-

alent

Z leadscrew: ISO 68 oil or NLGI No. 2 grease

GENERAL OILING

Assuming a clean environment – no abrasive particles

or machining debris – lack of proper lubrication is the

main cause of premature wear.

Before starting a work session, and every few hours

thereafter:

1. Check the level of oil in the gearbox.

2. Lubricate all ball oilers.

3. Apply the recommended oil or grease to the lead-

screws.

4. Operate the one-shot lube system (don't overdo —

one pump stroke will usually be enough).

5. To distribute the oil evenly run the headstock up/

down full travel, and the table full travel in X and Y

axes.

Quill rack and pinion

Lower and lock the quill. Using a sti ux brush, clean

the visible portions of the rack and pinion. Raise and

lower the quill to expose the remainder of the working

surfaces, locking and cleaning at each setting.

Remove all machining debris and foreign ob-

jects before lubricating ANYTHING! If need

be, any oil is better than no oil – but use the

recommended lubricants when you can.

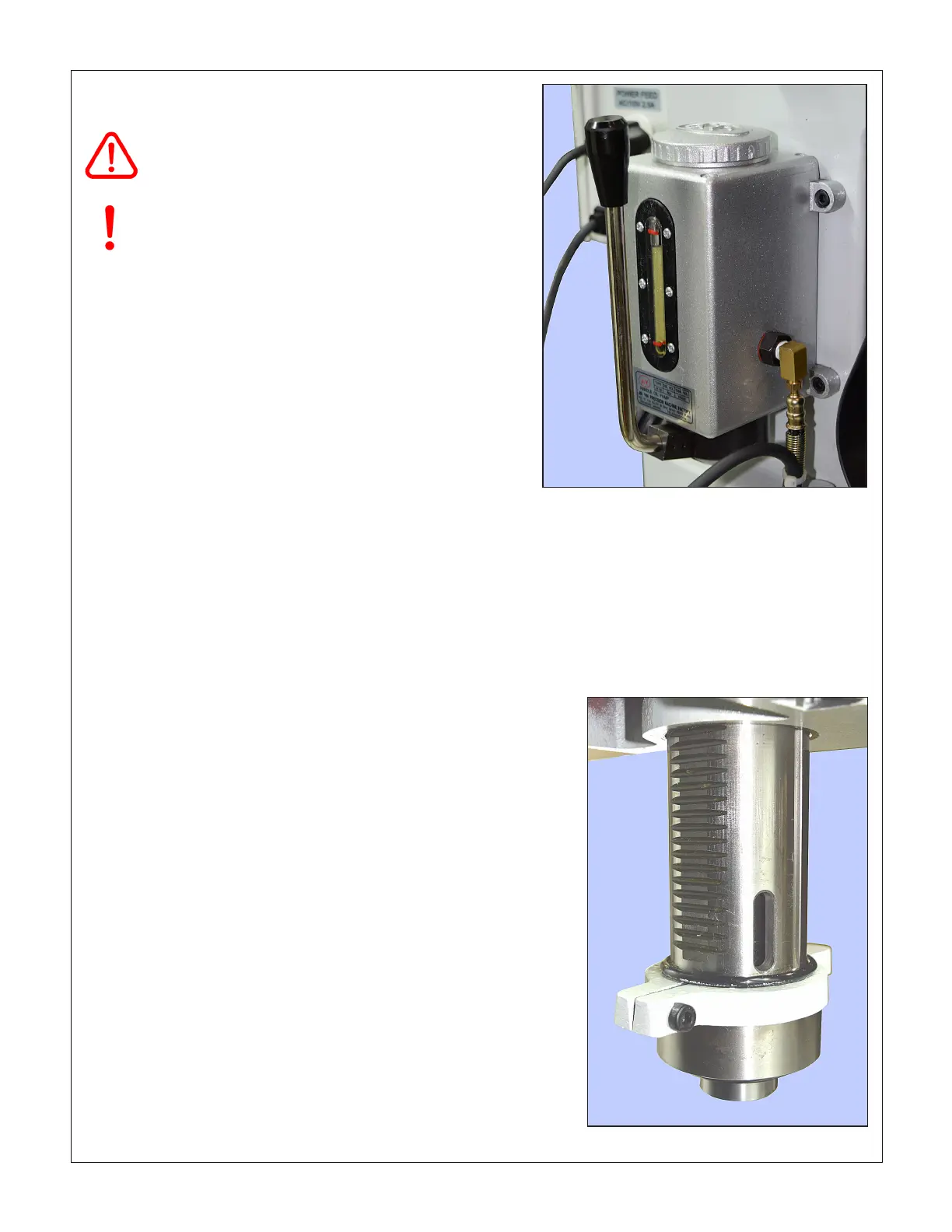

Figure 4-1 One-shot lube reservoir

Operate the lever once before each work session, less

frequently if there are visible signs of oil accumulating.

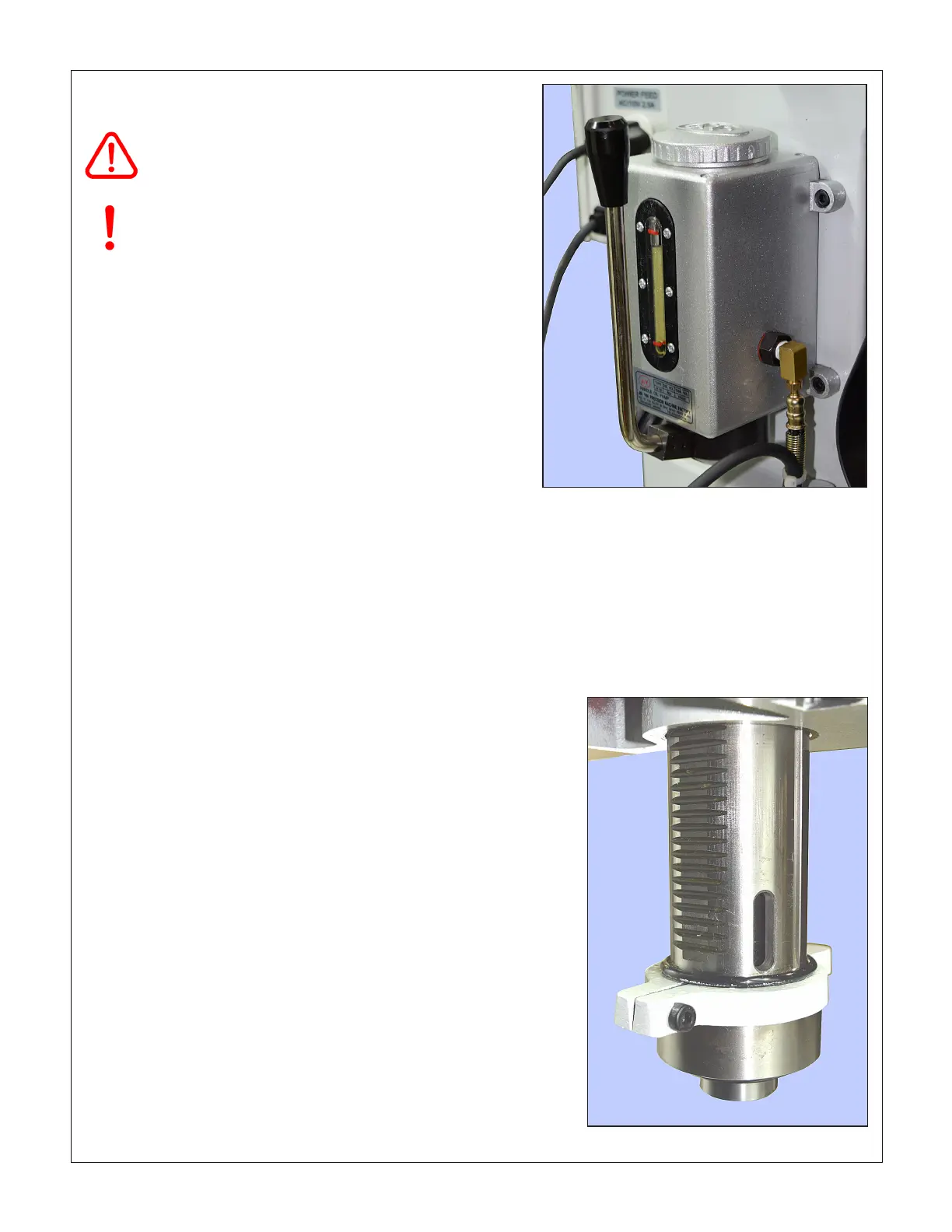

QUILL RACK & PINION

Lower and lock the quill, Figure 4-2. Using a sti ux

brush, clean the visible portions of the rack and pinion.

Raise and lower the quill to expose the remainder of the

working surfaces, locking and cleaning at each setting.

Apply grease to the gear teeth.

Figure 4-2 Quill rack

Loading...

Loading...