21

PM-833TV 4-13-21V1.indd Copyright © 2021 Quality Machine Tools, LLC

DOWNFEED RETURN SPRING TENSION

The quill should automatically retract when the coarse

downfeed levers are released following a drilling oper-

ation. If not the return spring, Figure 4-8, may need to

be re-tensioned or replaced – but rst check for other

issues such as obstructions or lack of lubrication.

Take extra care when working on the spring – it

can unwind violently if not properly controlled

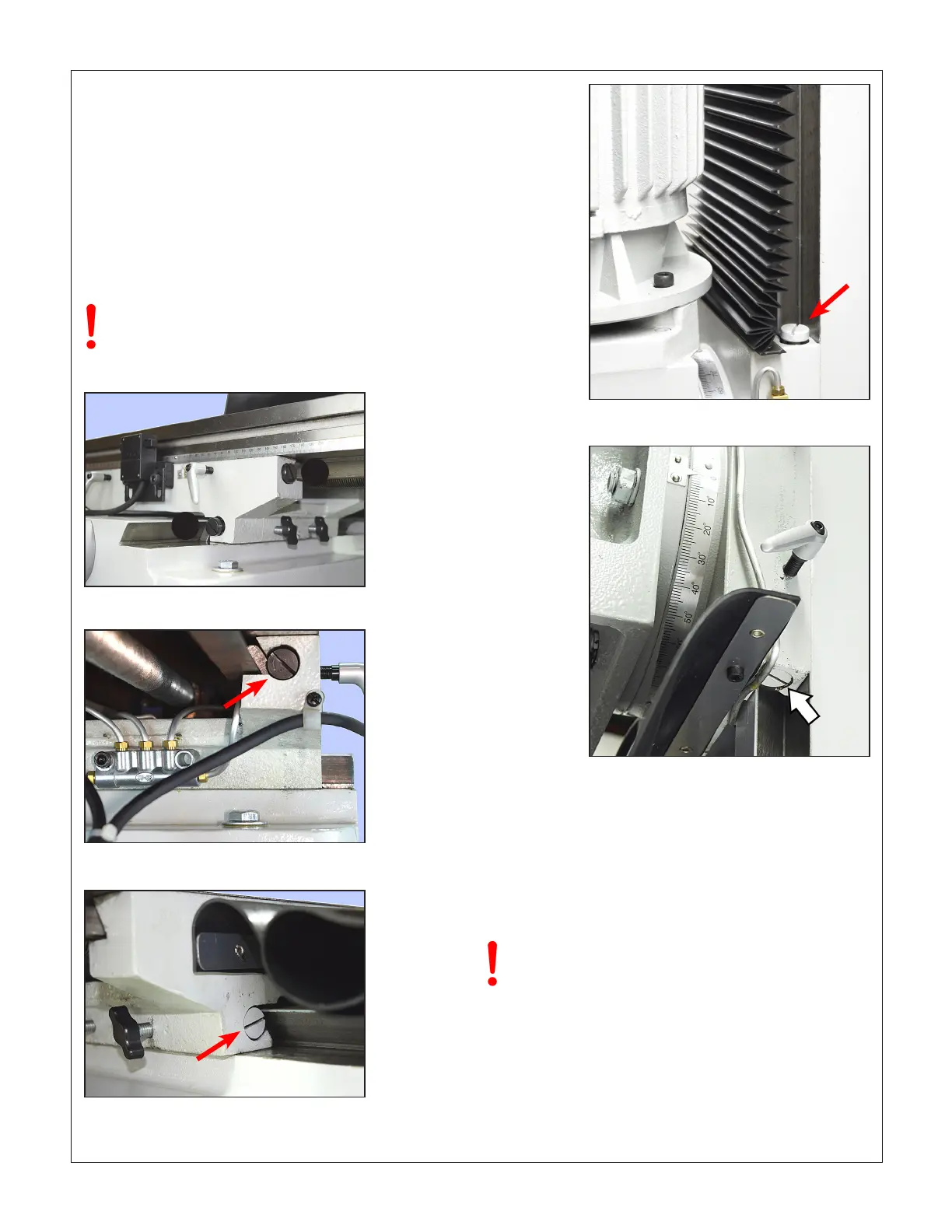

A stop pin in the headstock casting engages in one of

4 notches on the rim of the cup-shaped spring housing,

Figure 4-10. The inner tab of the spring ts into a slot in

the quill pinion shaft. A suggested procedure for adjust-

ing spring tension, or replacing a broken spring, follows.

1. Lower the headstock to bring the spindle nose close

to the table. Don't overdo this — be sure that the

GIB ADJUSTMENT

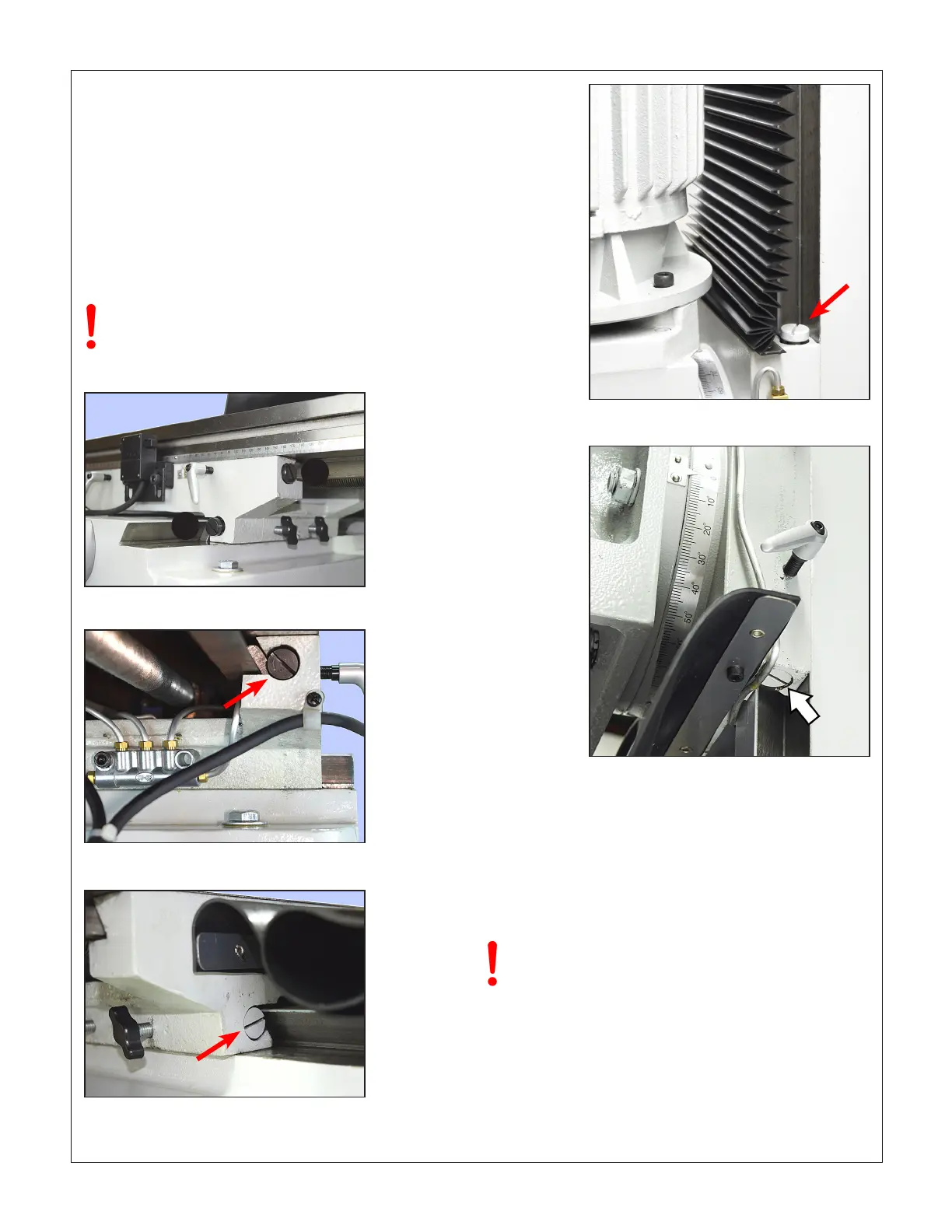

Gibs on the X, Y and Z axes control the t of the mating

dovetailed surfaces. They are gently-tapered lengths of

ground cast iron located by opposing screws at each

end. Adjusting them is a trial and error process that

takes time and patience. Aim for the best compromise

between rmness and reasonably free table movement.

Too tight means accelerated wear on the ways, lead-

screws and feed motors, if installed. Too free means

workpiece instability, inaccuracies and chatter.

BOTH gib screw heads must be tight against

the gib ends. If you loosen one, tighten the oth-

er. Remove the way covers for access to the

back of the Y gib and bottom of the Z gib.

Figure 4-3 Gib screws: X-axis RH (1), Y-axis front (2)

Figure 4-4 Gib screw: X-axis, LH

Figure 4-5 Gib screw: Y-axis, back

1

2

Figure 4-6 Gib screw: Z-axis, top

Figure 4-7 Gib screw: Z-axis, bottom

Loading...

Loading...