22

PM-833TV 4-13-21V1.indd Copyright © 2021 Quality Machine Tools, LLC

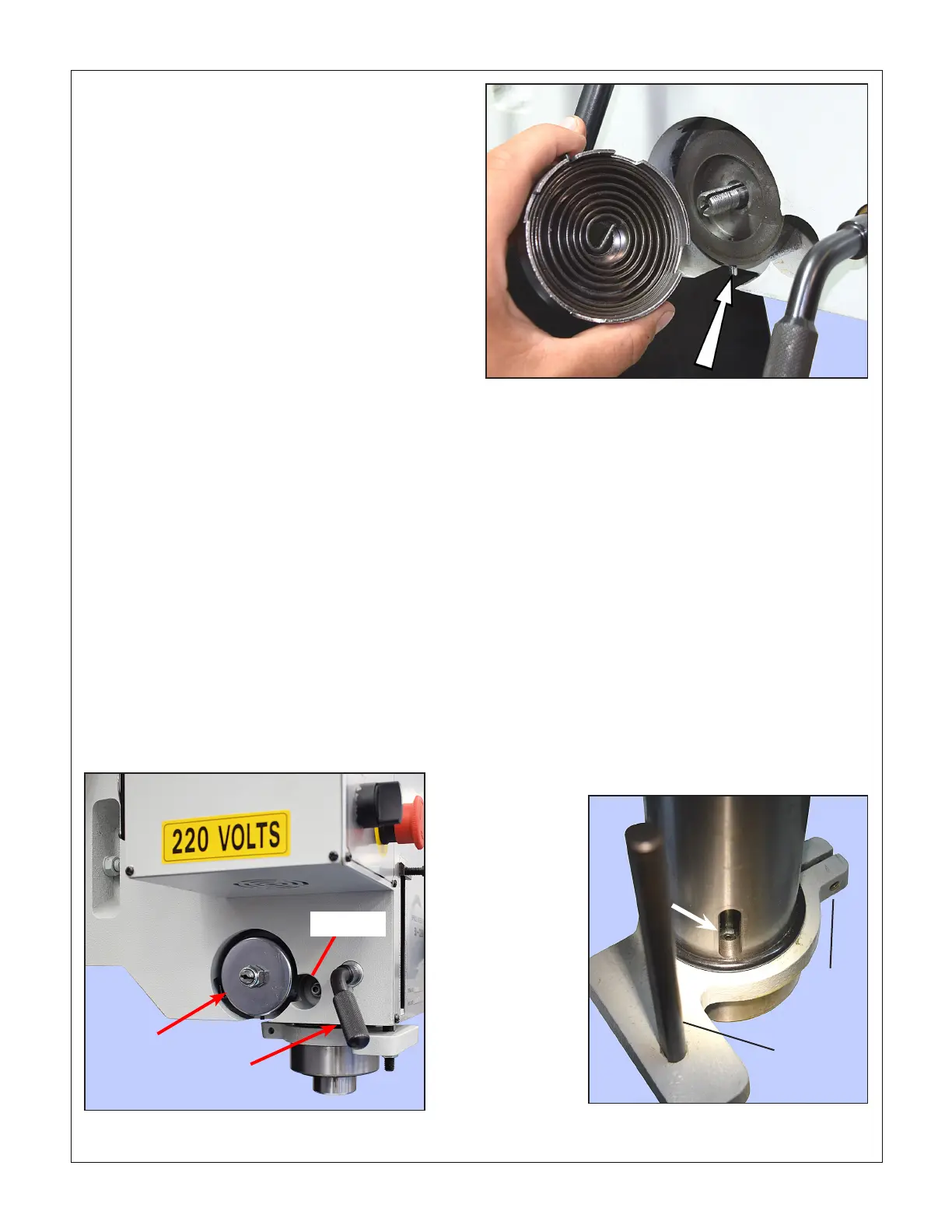

Figure 4-9 Return spring housing & stop pin

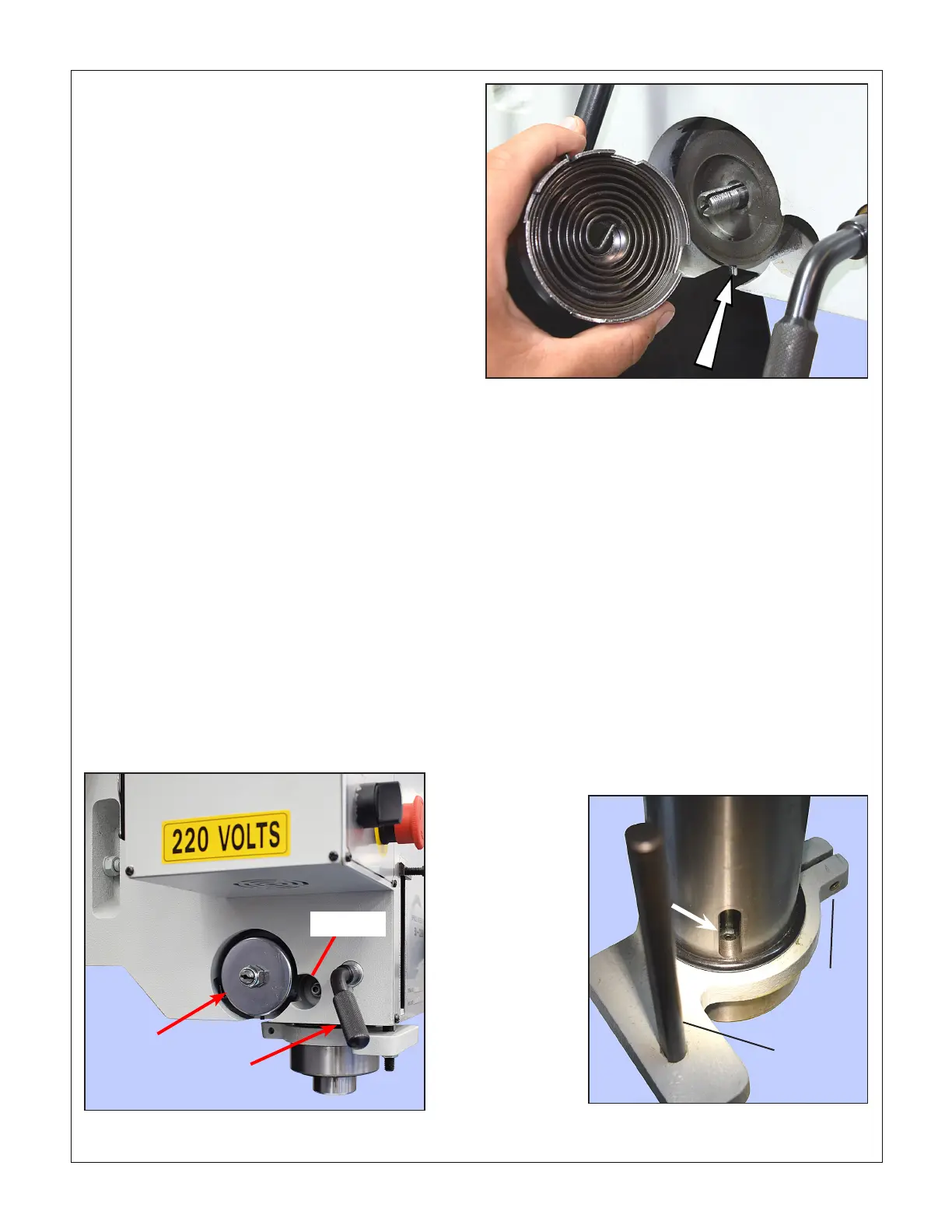

R8 COLLET LOCATING SCREW

R8 devices are located in the spindle by a set screw that

protrudes less than 3/32" beyond the inner wall of the

quill. The depth of the locating groove on R8 tooling var-

ies widely, in some cases slightly below spec. If your R8

devices meet spec, but consistently bind when inserted,

the inner screw may be in too far.

Early models of the PM-833TV came with a hex lock nut, Fig-

ure 4-10, to lock the screw in place. The lock nut is not acces-

sible without removing the entire quill and spindle assembly.

Figure 4-10 R8 locating screw

Quill

bracket

clamp

Depth

stop rod

How much return spring force?

There is no hard and fast rule. Most users set the spring

so that the quill can be fully extended without undue ef-

fort, returning close to zero extension when released,

assuming only a collet is installed (no drill chuck).

lube lines on either side of the headstock remain

clear of the leadscrew support block. Place scrap

wood under the spindle to protect the table in case

of accidents.

2. Fully retract the quill, then clamp it in place with

the locking lever, Figure 4-8. Wear leather gloves

throughout the following procedure.

3. While holding the spring housing in place, remove

the self-locking nut from the spring end of the quill

pinion shaft.

4. Using heavy duty needle-nose pliers, grasp the

spring tab outside of the spring housing. Bearing in

mind the sudden turning force stored in the spring,

ease the housing outwards, clear of the stop pin,

Figure 4-9, then relax the spring by allowing the

housing to spin.

Reinstalling the spring

1. Align the center tab of the spring with the slot in

the pinion shaft, then push the spring housing in to

engage the shaft, stopping with the housing rim just

outboard of the stop pin.

2. Using needle-nose pliers grasp the spring tab out-

side of the housing, then rotate the housing count-

er-clockwise to apply tension (the nose of the pliers

will be running in the gap between spring housing

and the machined cavity). When sucient tension

has been applied, ease the housing around a little

more, enough to align the stop pin with a notch in

the housing. Push the spring fully home, seating it

squarely in the machined cavity. Plan on rotating the

spring housing at least one-half turn.

3. Replace and tighten the self-locking nut.

4. Unlock the quill to test the return spring function.

Re-tension if necessary to achieve the desired

spring force.

Figure 4-8 Quill return spring

Return

spring

housing

Quill

locking

lever

Dog screw

Loading...

Loading...