7

PM-833TV 4-13-21V1.indd Copyright © 2021 Quality Machine Tools, LLC

UNCRATING THE MILL

The PM-833TV mill and stand are usually shipped in

separate containers. In special instances, the mill and

stand may be shipped pre-assembled Before moving

the mill, check the two Special Precautions on the pre-

ceding page: 1. Oil line protruding from the column, Fig-

ure 2-1, and; 2. (if the headstock is power-assisted) Z

axis limit stops.

INSTALLING THE MILL

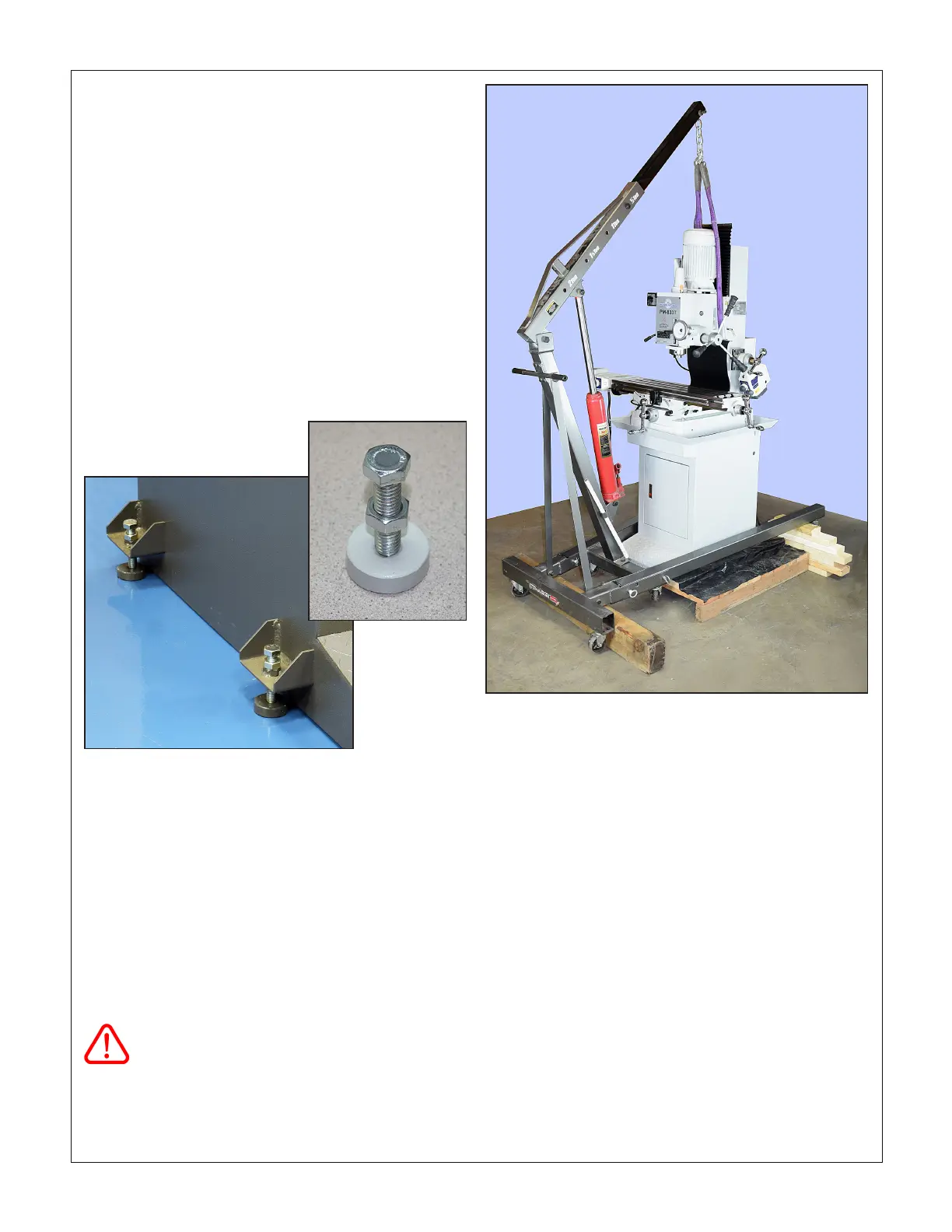

Check local codes for machine tool fastening require-

ments. If none is specied, the leveling mounts supplied

can be used, Figure 2-3, or the mill stand can be perma-

nently anchored to the oor. The leveling mount screws

are installed, hex heads up, in weld nuts on the stand

wings. The screws are centered by indentations on the

upper surface of the pads.

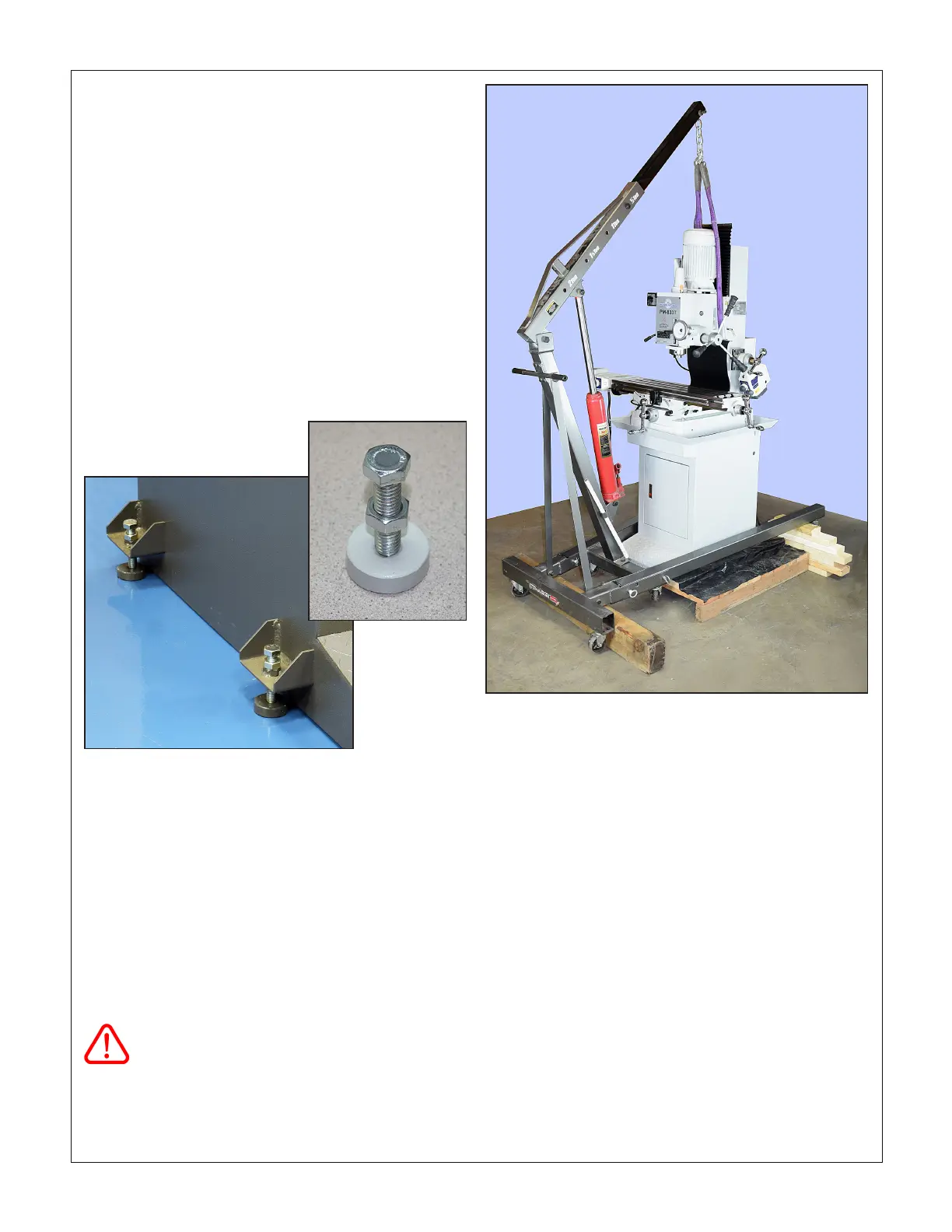

MOVING THE MILL (using slings)

If available, use a forklift to handle the mill. An engine

hoist can be used instead, but this may require some

experimentation along the lines suggested below.

The following notes assume that the mill is pre-in-

stalled on its stand. If the mill and stand were

shipped separately, the engine hoist must have

similar reach and lifting capability to raise the mill

above the surface of the stand.

The main objective of the procedure suggested here is

to lift the mill just enough to allow the pallet to be re-

moved. Thereafter the engine hoist can be used to roll

the mill to its working location.

This is at least a two-person procedure!

Figure 2-4 Using an engine hoist (File photo, Model PM-833)

1. Set the upper arm of the hoist as far out as possible

— but not beyond the point where its lifting capacity

is less than 1500 lb.

2. Remove the lag bolts, etc., securing the mill to the

pallet.

3. Roll the hoist over the pallet to bring the lift chain

directly over the graduated tilt scale at the back of

the headstock, Figure 2-4. Depending on the style of

hoist the legs will likely now be resting on the pallet,

with the casters clear of the oor.

4. At the cylinder end of the hoist insert an 8 x 8 or sim-

ilar wood beam under the legs to raise them clear

of the pallet (lift the hoist by hand, or use a jack).

Beam size is arbitrary, but the legs must be above

the pallet.

5. At the open end of the hoist lift each of the legs in

turn to insert similar wood blocks — or piles of scrap

material as in the photo. (All support material must

clear of the pallet to allow it to be moved away when

unweighted in the following steps).

6. Check that the headstock is fully lowered, spindle

just clear of the table.

Figure 2-3 Supplied leveling mounts

The leveling screws are 1/2-12 TPI, usually unavailable in the U.S.

If extra length is needed, install booster pads under the round pads

supplied.

Loading...

Loading...