Section 7: Appendix

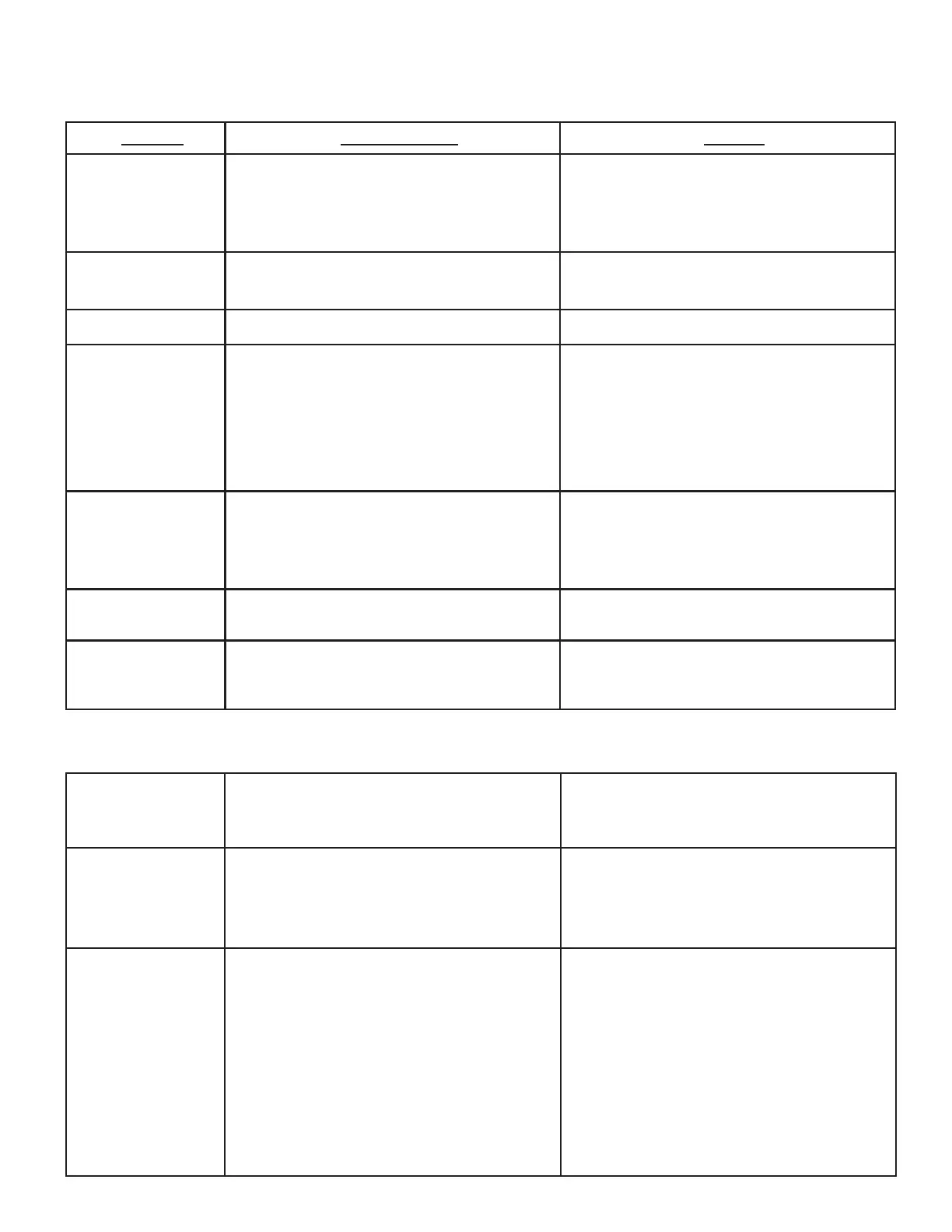

Mower

Troubleshooting

Problem

Probable Cause

Remedy

Mower Vibration

∗

Mower not being operated at rated 540 RPM speed.

∗

Possible build up of material on blade spool.

∗

Bent or Broken Blade.

∗

Blades unequal weight

∗

Set tractor throttle for proper PTO speed.

∗

Clean blade spool.

∗

Replace blades, refer to page 22.

∗

Replace blades, refer to page 22.

Noisy Mower

∗

Loose components.

∗

Low oil in gearbox.

∗

Check all bolts for tightness.

∗

Check PTO clearances with Tractor drawbar, etc.

Mower Will Not Cut

∗

Slip Clutch Slipping. Adjust slip clutch according to instructions on page 15.

Clippings Discharges

From Mower Along

Sides or Unevenly

∗

Grass Too High or Dense.

∗

Wet Grass.

∗

Rear of mower too low, trapping clippings under mower.

∗

Reduce ground speed but maintain 540 RPM at tractor

PTO, OR

∗

Make two passes- raise mower cutting height for first

pass and lower to desired cutting height for second pass.

∗

Allow grass to dry before mowing. Slow ground speed

but maintain tractor RPM 540. Cutting lower will help.

∗

Refer to page 15for leveling & adjusting cutting height.

Uneven Cut

∗

Mower not level side to side or incorrect deck tilt.

∗

Possible build-up of clippings under mower.

∗

Worn or bent blades.

∗

Excessive ground speed.

∗

Refer to page 13 for leveling deck.

∗

Clean mower.

∗

Replace blades, refer to page 22.

∗

Reduce ground speed.

Rapid Blade Wear

(Cutting Edge)

∗

Blade contacting ground.

∗

Adjust mower to operate at height that will eliminate

ground contact.

Rapid Blade Wear

(Bolt Hole)

∗

Mower not operating at rated 540 RPM Speed.

∗

Too much ground speed.

∗

Reduce ground speed. Set tractor throttle for proper

PTO Speed.

∗

Use lower gear.

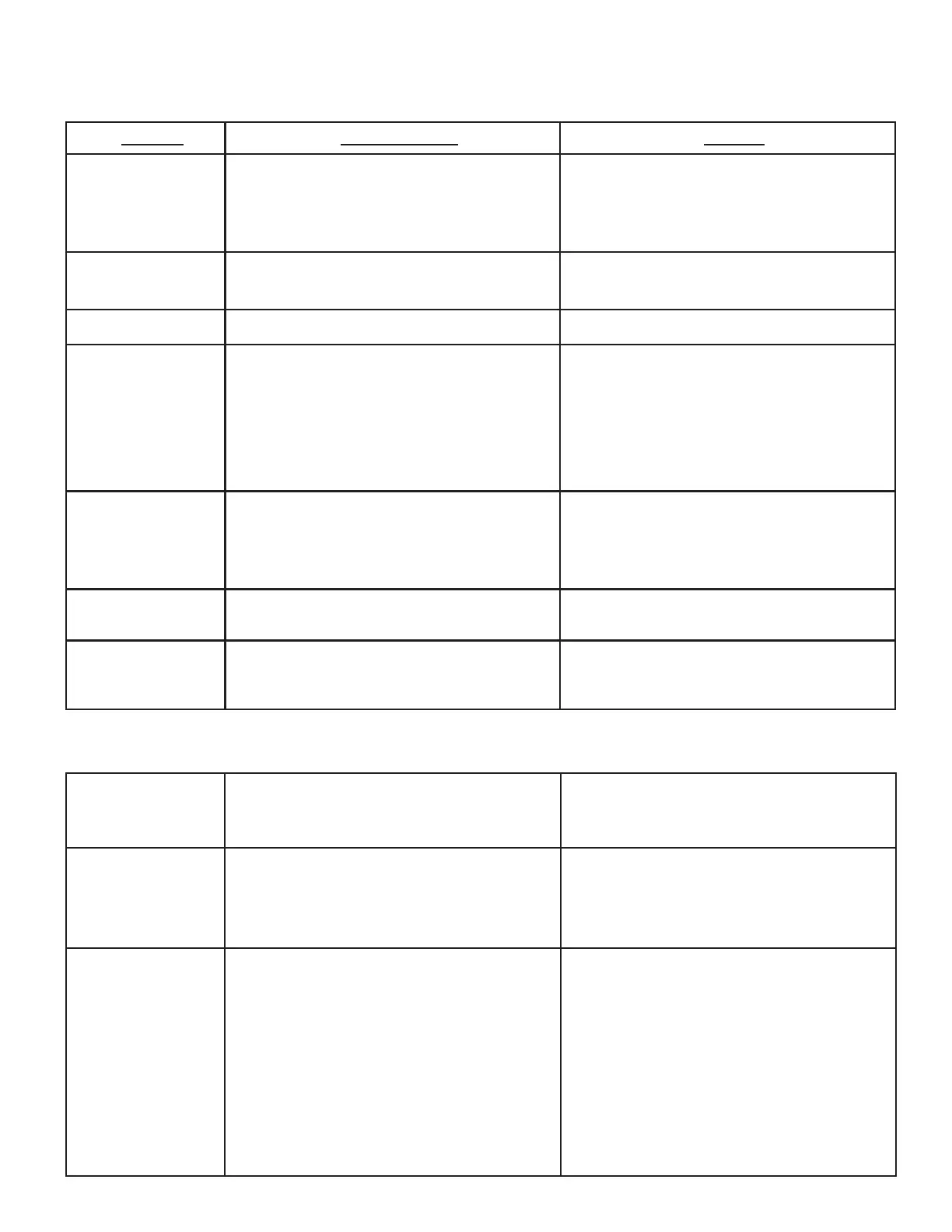

Gearbox

Troubleshooting

Gearbox Overheating

∗

Low on lubricant.

∗

Improper type of lubricant.

∗

Excessive trash build-up around gearbox.

∗

Fill to proper level.

∗

Replace with proper lubricant.

∗

Remove Trash.

Gearbox Noisy

∗

Rough Gears.

∗

Worn Bearings.

∗

Low oil in gearbox.

∗

May be normal when new.

∗

Run-in or change gears.

∗

Replace bearing.

∗

Check level and add oil.

∗

Allow for initial break-in.

Gearbox Leaking

∗

Damaged oil seal.

∗

Bent shaft.

∗

Shaft rough in oil seal area.

∗

Oil seal installed wrong.

∗

Oil seal not sealing in housing.

∗

Oil level too high.

∗

Gasket damaged.

∗

Bolts loose.

∗

Improper type of lubricant.

∗

Replace seal.

∗

Replace oil seal and shaft.

∗

Replace or repair shaft.

∗

Replace seal.

∗

Replace seal or use a sealant on outside

diameter of seal.

∗

Drain oil to proper level.

∗

Replace gasket.

∗

Tighten bolts.

∗

Replace with proper lubricant.

30

Loading...

Loading...