20 © 2016 Proceq SA

3.3.2.4 Test Conditions

To ensure proper hardness readings, the following conditions must be

fulfilled. If one or more conditions are not met, the result may be signifi-

cantly false.

Probe setup 50 N

probe

with

clamp

50 N probe

with round

standard

foot (ø =

42 mm)

50 N

probe

with

tripod

50 N probe

with spe-

cial feet

Minimum test

piece thickness

1 mm at ~20 HB

130 μm at ~70 HRC

Maximum test

piece thickness

40 mm N/A

Test piece surface

condition

recommended mean surface roughness

R

a

< 2 μm to minimize data scatter

Surface

curvature

foot to be

used for

plane

surfaces

very

small cur-

vatures

accepta-

ble

18 – 70 mm

radius of

curvature or

70 mm – ∞

Maximum test

piece hardness

70 HRC

Minimum spacing

three times the diameter of a test indentation

Table 3: Portable Rockwell Test Piece Requirements

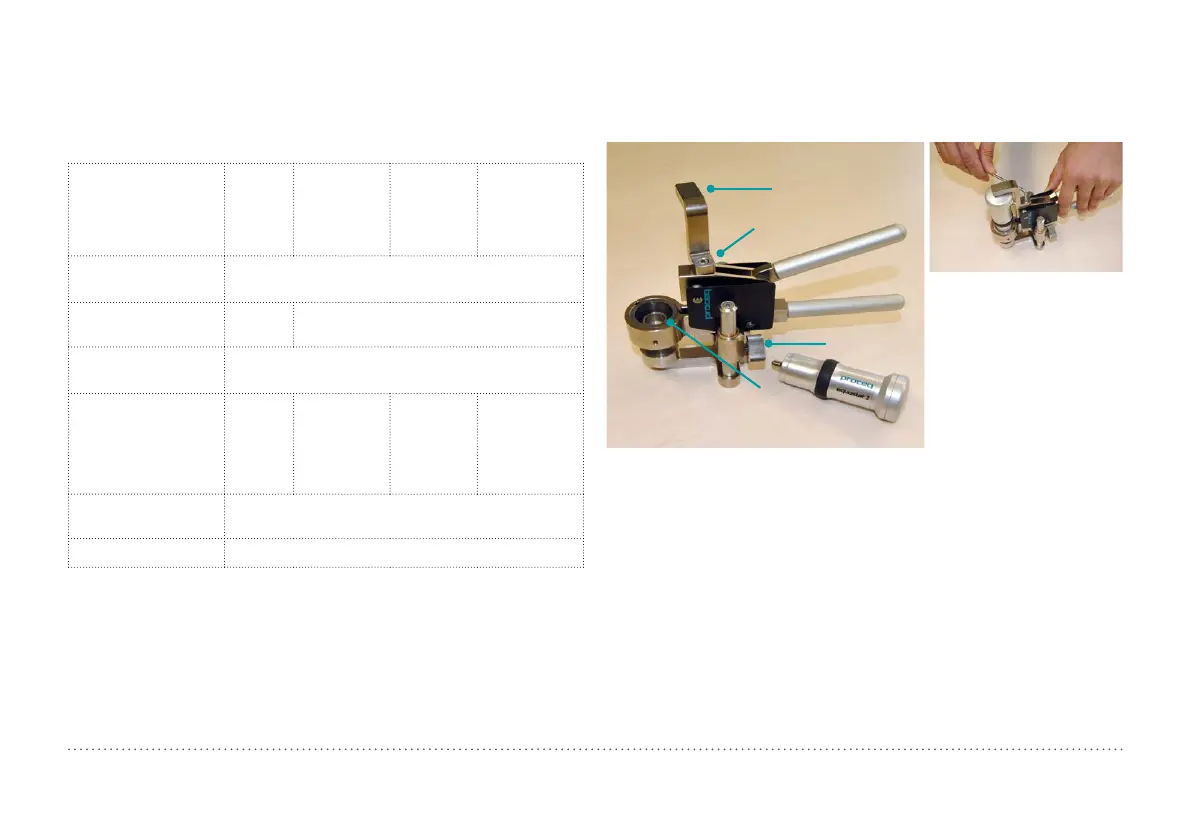

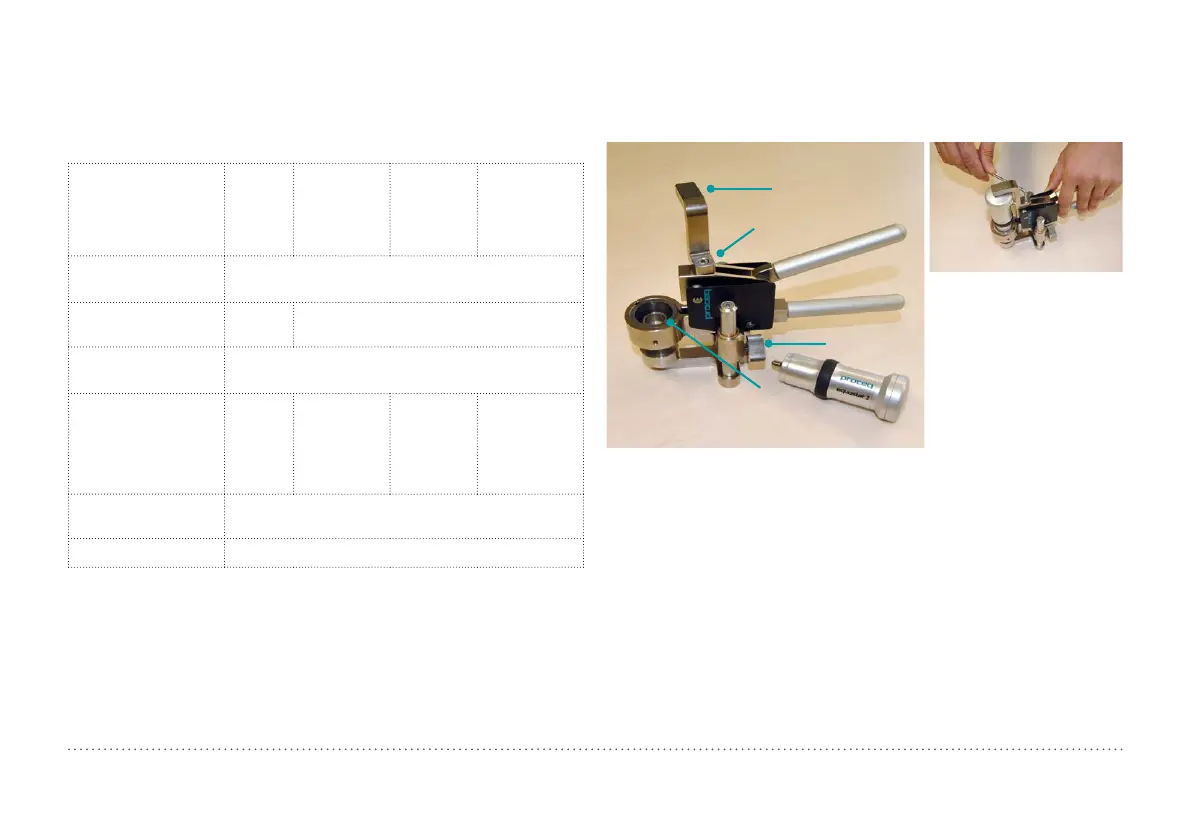

3.3.2.5 Installing the Measuring Clamp

The clamp is designed to facilitate the hardness testing of very thin or

small samples.

Cantilever

Cantilever screw

Knurled screw

Probe holder

Figure 16: Portable Rockwell Clamp

• Use the 3 mm Allen key setup tool to release the cantilever. Turn it by 90°.

• Take the probe and remove the foot. The diamond indenter remains

mounted.

• Screw the probe into the probe holder of the clamp clockwise (hand-tight).

• Turn the cantilever so its tip is centred over the probe; tighten the can-

tilever screw securely using the 3 mm Allen key setup tool.

• The recommended clearance between the bottom of the probe holder

and the sample surface should be between 2 and 5 mm. Adjust the

height with the two knurled screws.

Loading...

Loading...