Disposal

Support Material

Support material has no known regulatory requirements and may be disposed of in ordinary oce waste.

Spilled Material

Spills of material are unlikely, and should NOT occur in normal operation of the 3D printer system.

Spills of support material can be cleaned without the use of protective gear, and disposed of as oce waste.

Promptly remove spilled materials, dispose of waste materials, and clean up materials per local regulatory requirements.Small spills of uncured

liquid part material can be cleaned up using disposable towels, non-reusable rags, or absorbent materials to clean spills outside of the

printersuch as sawdust, clay, diatomaceous earth, or activated charcoal and placed into containers for transfer to an approved waste disposal

site.

Caution: Never put sawdust, clay, diatomaceous earth, or activated charcoal inside the printer, doing so will damage the printer.

If spilled material is hot (liquid), wait until it cools before wiping up. Use of heat above 65° (149°F) may prove helpful in removing spilled support

material from carpet. After wiping up the spill, wipe surface with denatured or isopropyl alcohol and clean thoroughly with soap and water.

Some cleaning solvents are highly ammable such as denatured alcohol and isopropyl alcohol. Before using solvents to clean and remove

uncured part material, be sure read and follow thesolvent suppliersafety precautions and recommended usage.

Flammability Hazards

Though the U.S. Department of Transportation does not consider VisiJet materials a "ammability hazard," they do classify them "combustible"

based on ash points. Material containers may rupture when exposed to extreme heat. Use National Fire Protection Association Class B

extinguishers such as carbon dioxide, dry chemical, or foam.

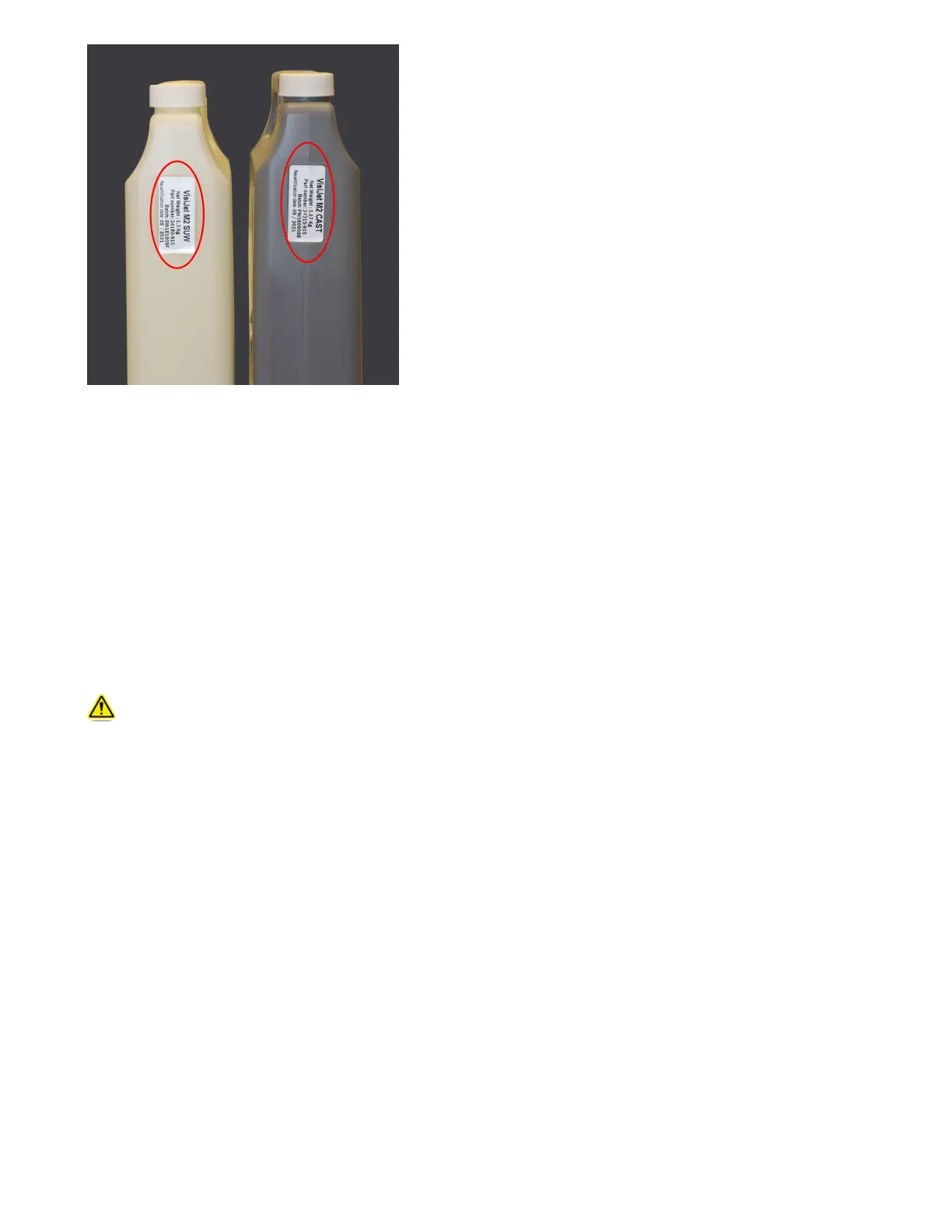

Loading...

Loading...