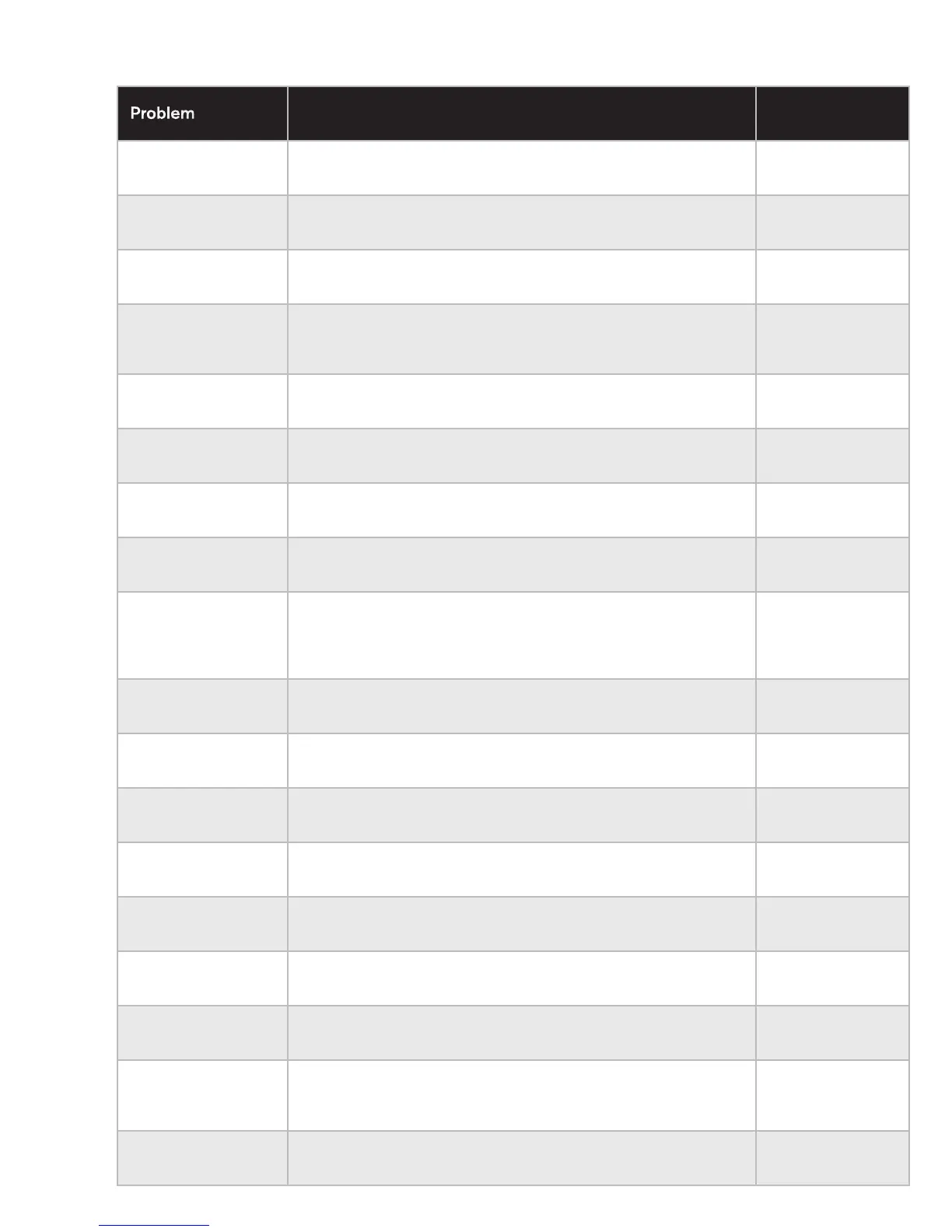

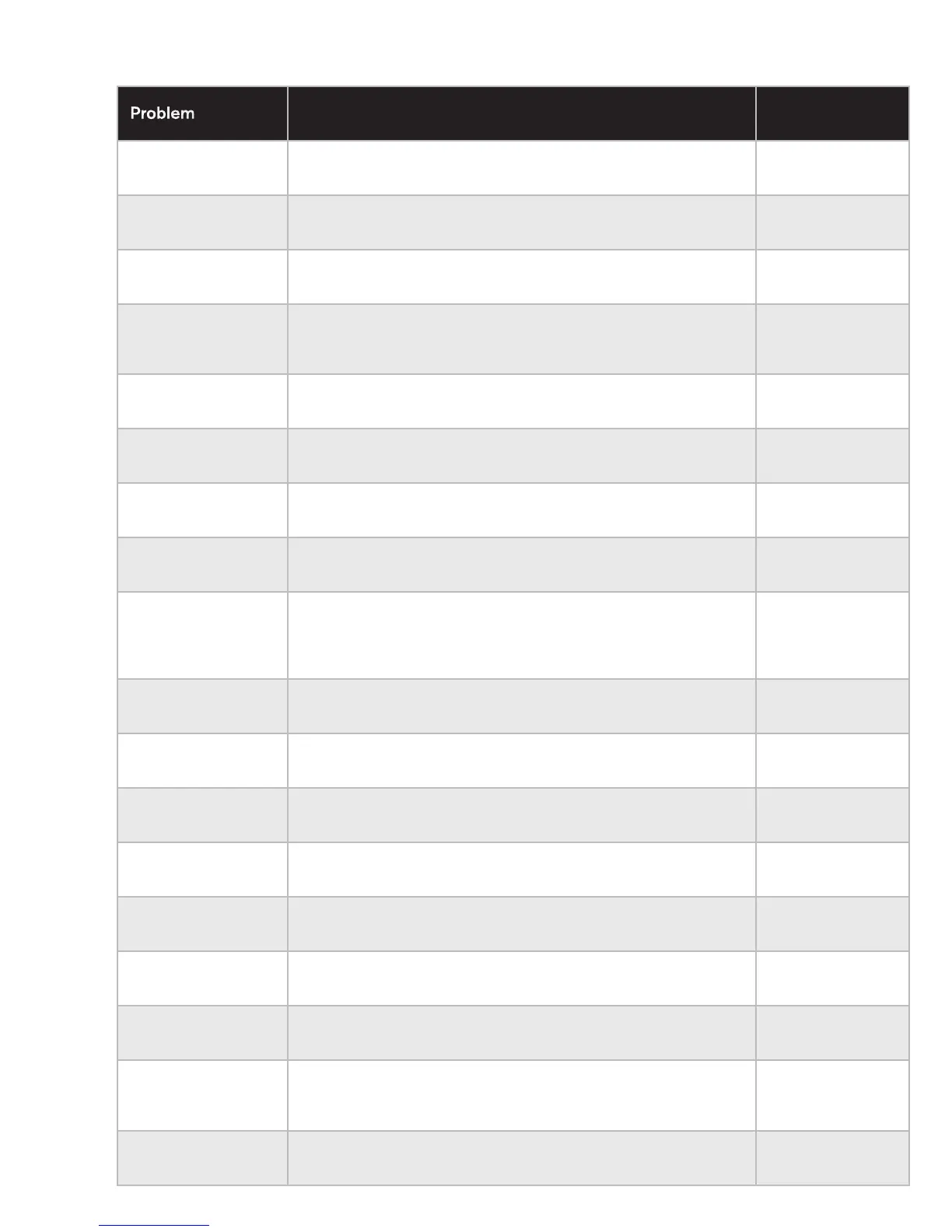

TROUBLESHOOTING

Problem Recommendation Notes

1. No Power Unit

Disconnect the black and gray cords at the barrel connector. Reconnect

making sure they are tight. If there is no power, slightly turn the adapter to

engage the two and tighten. Repeat as necessary.

2. Power to unit but

buttons don’t work

Disconnect the black and gray cords at the barrel connector. Reconnect

making sure they are tight. If there is no power, slightly turn the adapter to

engage the two and tighten. Repeat as necessary.

3. Pump is not working

Disconnect the power cord from outlet and from the FlexiPump unit. Recon-

nect the cord and plug in. Press a control button to see if it works

If it still doesn’t work,

go to #4

4. Pump does not work

Reset the unit by hitting stop, and then press the Forward Flush 30-second

button.

If it still does not

operate, contact Pure

Processing Customer

Service.

5. Rotor is spinning but

no solution is coming

out the end of the device

Make sure the drop-down tube is fully submerged. Also check for kinks in

the tubing. Make sure you have the correct end of the tubing in the solution.

6. Luer lock is broken

or separated from the

tubing

Change the tube set.

7. Devices are not clean

Check the device manufacturer’s cleaning recommendations. Check the

disinfectant instructions for use. Confirm that all directions have been prop-

erly followed.

8. Impact Cycle is not

working

Impact Cycle works in conjunction with detergent. Ensure that proper

detergent is used for the type of soil in the device (protein-based enzyme

for blood, e.g.).

If still not working,

see #7

9. Impact Cycle is not

flushing

Conduct a flow validation test:

1. Place drop-down tube into container of clean water

2. Press the Forward Flush button once for a 30-second flush

3. When a steady stream of water exits the connector, press the Stop

button

If it still does not

operate, contact Pure

Processing

Customer Service.

10. Water is leaking

from under the cap

1. Check the tube set for cracks

2. Change the tube set if cracked

11. One or more

components on the

tube set are broken

Replace the entire tube set

12. Unit is not running

and I have a red

blinking light

Allow the unit to cool down for 30 minutes, and then resume use.

Contact us if this does not remedy the issue.

This can occur after

prolonged use.

13. Speed control is

stuck on HIGH

Allow the unit to reset for 15 seconds. Press the speed control to test.

14. Unit makes a lot of

noise

Use a surface liner under the nest to reduce vibration

15. Unit stopped while

flushing

Unplug the unit to reset it. Repeat interrupted flushing cycle

16. Pump cap will not

stay locked to the base

Replace the cap

Probably cracked or

broken where locks

engage

17. My tube set is

leaking

Unscrew the threaded tube set nut from the connector on both the red and

white sides. If the tube has slid off the connector, push it back into place

until it is snug. Re-screw the tube set nut tightly so that no threading is

visible.

Please contact Pure

Processing Customer

Service if additional

help is required.

18. There’s a tear in my

tube set

Replace your tube set. Most tears occur because the lubrication on the

tube set was removed. The lubricant is necessary to prevent the pump from

overexertion and unnecessary strain.

16

FlexiPump™ Independent Flushing System User Manual

© Pure Processing, LLC. 2017. All rights reserved.

Loading...

Loading...