6 QSC Audio Products, LLC

Solder

1.4 The well-equipped service bench

To properly service RMX amplifiers, a technician needs the right tools. The

technician’s service bench should have the following equipment:

• Digital multimeter with RMS AC voltage and current

• Digital clamp-on ammeter

• Dual-trace oscilloscope

• Audio distortion analyzer

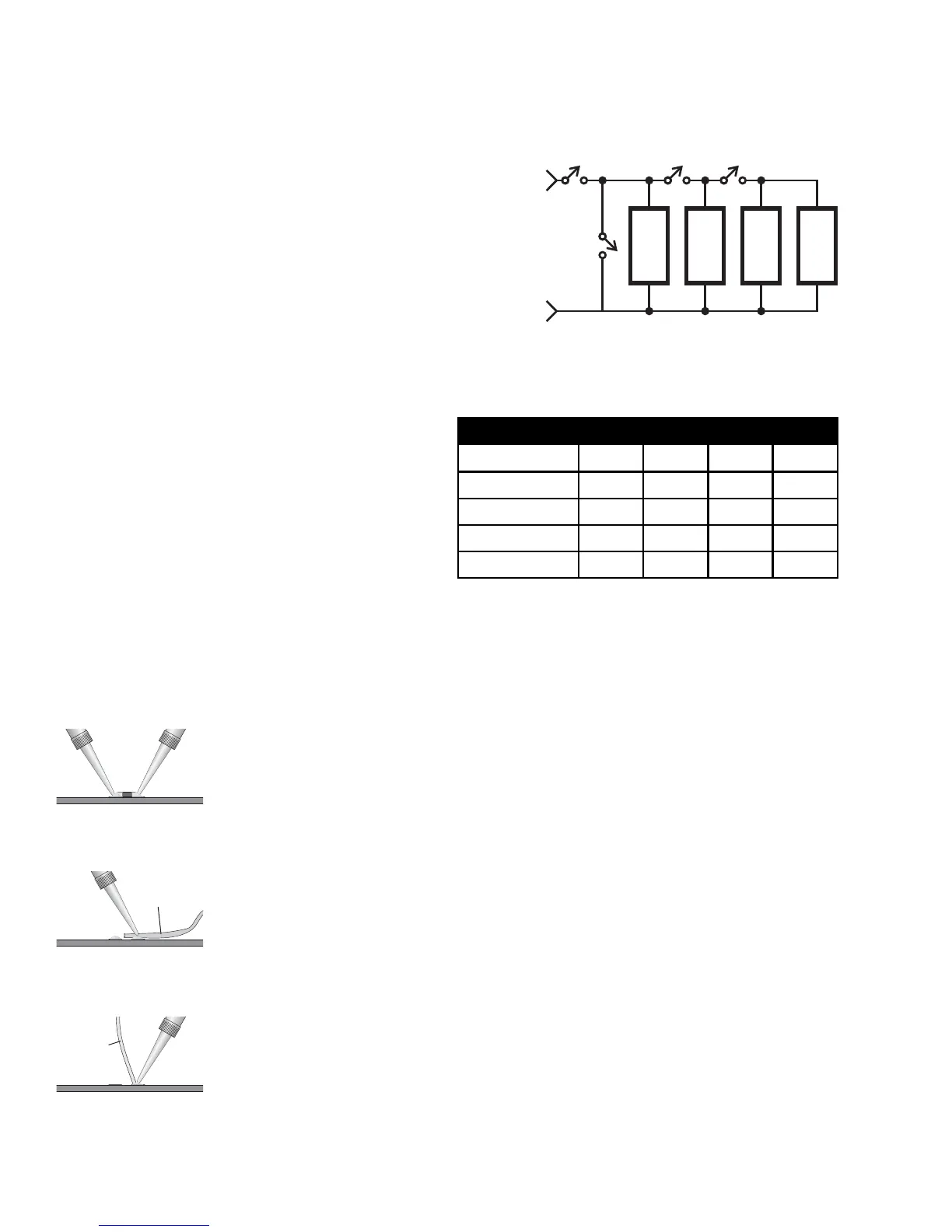

• Non-inductive load resistors, configurable as 8 ohms (min. 500 watts capacity),

as 4 ohms (min. 750 watts capacity), and 2 ohms (min. 1200 watts capacity);

see Figure 1.2 and Table 1.1.

• Variable AC voltage source, such as a Variac or Powerstat variable trans-

former, with a rated current capacity of up to 25A (for 120V models) or 12A (for

230V models)

• Low-distortion audio sine wave generator

• Philips and flat screwdrivers

• Soldering iron with a fine tip, 25–60W recommended (if you

service both RoHS-compliant and non-compliant amplifiers, you

will need separate soldering and desoldering equipment for

each)

• Appropriate rosin-core solder (use only RoHS compliant lead-

free solder for RoHS-compliant amplifers; for non-RoHS

amplifiers, use a 60/40 or 63/37 Pb/Sn alloy)

• Long-nose pliers

• Diagonal cutters

• Wire strippers

Automated test equipment, such as an Audio Precision workstation, is very useful for servicing RMX amplifiers. Contact QSC Technical

Services to obtain applicable AP test files.

Solder braid

1.5 Working with surface-mount components

RMX amplifiers, like many modern electronic products, use surface-mount technology (SMT) components

where appropriate in order to make high-density circuitry that is reliable and economical to manufacture.

SMT components in the RMX amps are used in the small-signal and control circuits, so they do not handle

significant amounts of power; therefore, they are subject to very little stress and should seldom fail.

Sometimes they do fail, or they require replacement for a performance upgrade or modification. Thus, it is

important to know how to work with SMT components.

Specialized tools and equipment exist for soldering, unsoldering, and removing SMT components quickly

and efficiently, but they are often expensive. Most SMT repairs, though, can be handled reasonably well with

common tools and equipment, such as tweezers, solder braid, and fine-tip soldering irons. The original

factory components are tacked to the board with a spot of glue, so you might have to apply some force to

break the adhesive.

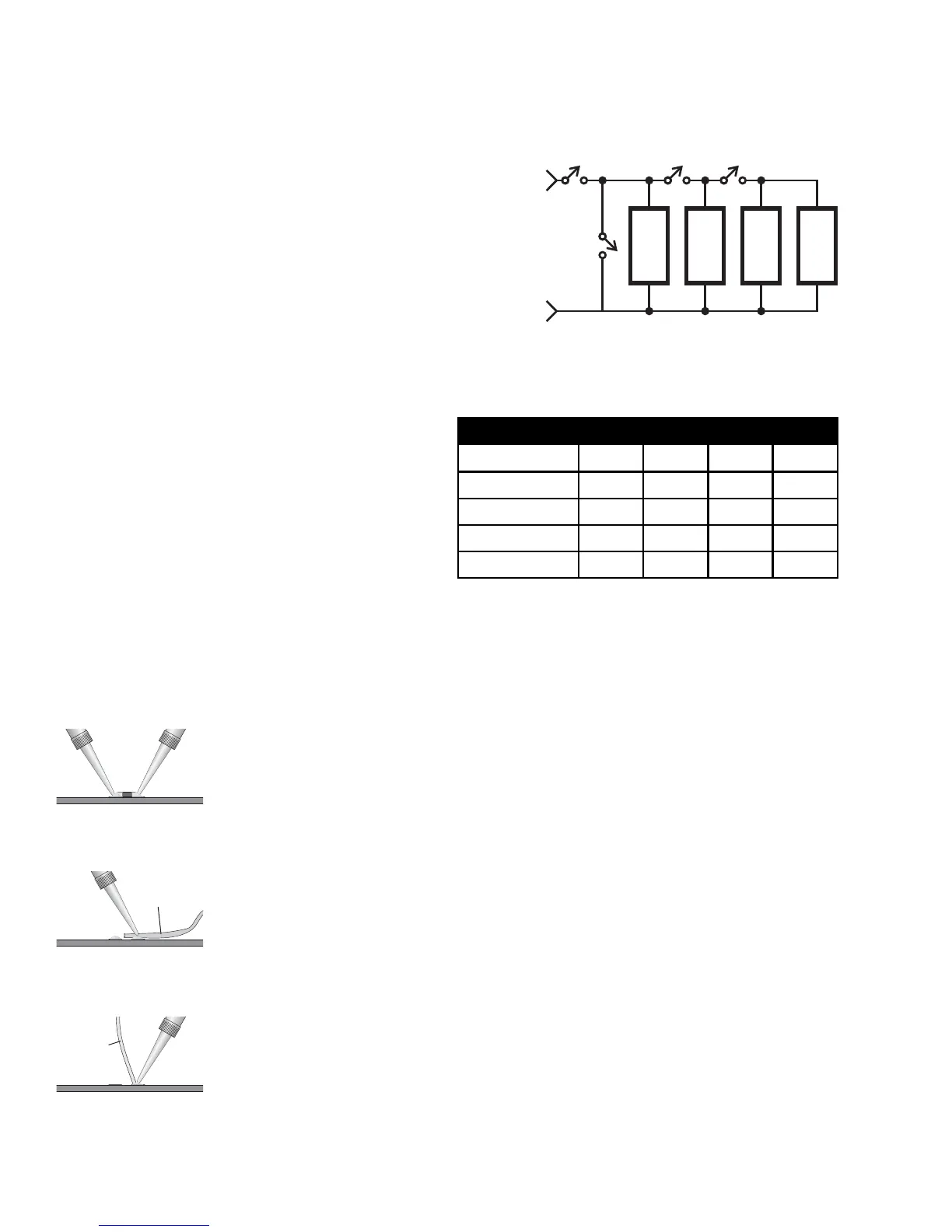

Two-terminal components (resistors, capacitors, diodes, etc.)

Removal

1 Use two soldering irons, preferably about 25 to 40 watts, with fine tips.

2 With a soldering iron in each hand, hold one tip on the solder at one end of the component and the

other tip on the other end (Figure 1.3).

3 Once the solder melts on both ends, grip the component between the two tips and lift it from the

circuit board.

4 Use solder braid and a soldering iron to remove the solder from the two pads (Figure 1.4).

Figure 1.2. Load resistor bank

Table 1.1. Load resistor bank switch truth table

SW1 SW2 SW3

SW4

8Ω 8Ω 8Ω 8Ω

R1: 8 , 500W non-inductiveΩ

R2–R4: 8 , 300W min. non-inductiveΩ

R1 R2

R3 R4

SW1 SW2 SW3 SW4

∞Ω (no load)

OFF•••

8Ω

ON OFF OFF OFF

4Ω

ON ON OFF OFF

2Ω

ON ON ON OFF

0Ω (short circuit)

ON • • ON

Figure 1.5.

Figure 1.3.

Figure 1.4.

Loading...

Loading...