8.2 Electric cable size and fuses

Important

• The voltage on the compressor terminals must not deviate more than 10% of the

nominal voltage.

It is however highly recommended to keep the voltage drop over the supply cables

at nominal current below 5% of the nominal voltage (IEC 60204-1).

• If cables are grouped together with other power cables, it may be necessary to use

cables of a larger size than those calculated for the standard operating conditions.

• Use the original cable entry. See section Dimension drawings.

To preserve the protection degree of the electric cubicle and to protect its

components from dust from the environment, it is mandatory to use a fitting

cable gland when connecting the supply cable to the compressor.

Use single core cables in conduit if two multicore cables do not fit in the supply

cable entrance.

• Local regulations remain applicable if they are stricter than the values proposed

below.

• Currents are calculated with the full service factor but we suggest to add 10% due

to over- and under-voltage.

Fuses are maximum allowed values calculated for full service factor and 10%

over- and under-voltage.

• Caution:

• Always double-check the fuse size versus the calculated cable size. If

required, reduce fuse size or enlarge cable size.

• Cable length should not exceed the maximum length according to IEC 60204

table 10.

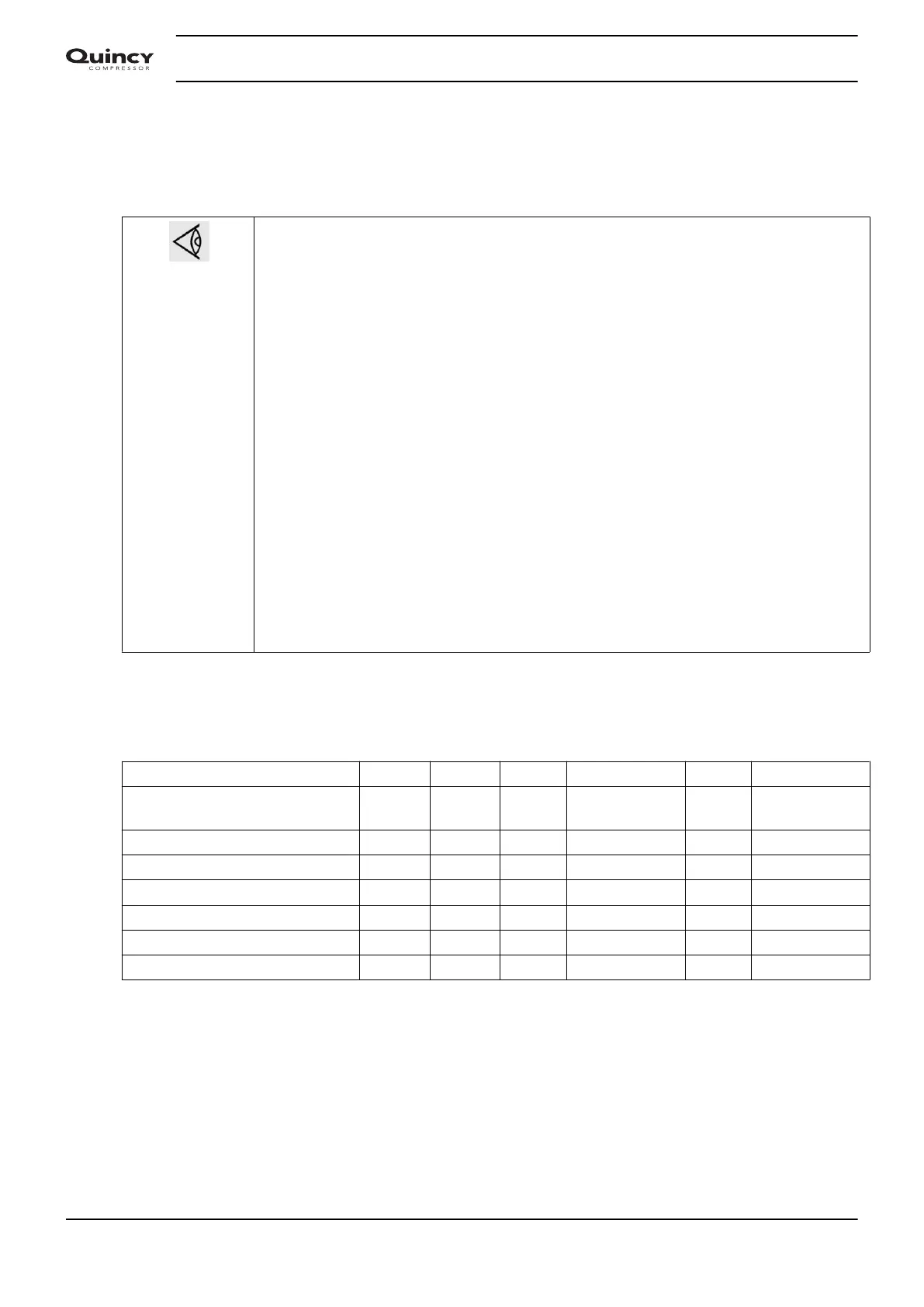

Currents and fuses

UL/cUL approval

Compressor type I (1) Max. fuse (1) I (2) Max. fuse (2)

K5/

HRC form II

K5/

HRC form II

V Hz A A A A

QGD 40 230 60 298.2 350 306.2 350

QGD 40 380 50 176.8 200 180.9 200

QGD 40 380 60 179.4 200 184.2 200

QGD 40 460 60 149.4 175 153.5 175

QGD 40 575 60 120.4 150 124.0 150

Instruction book

98 2920 7190 02

Loading...

Loading...