9 Technical data

9.1 Electric cable size

Attention

The voltage on the compressor terminals must not deviate more than 10% from the

nominal voltage.

It is however highly recommended to keep the voltage drop over the supply cables at

nominal current below 5% of the nominal voltage.

If cables are grouped together with other power cables, it may be necessary to use

cables of a larger size than those calculated for the standard operating conditions.

Use the original cable entry. See section Dimension drawings.

The compressor is delivered with 3 m (10 ft.) cable and a fitting cable gland.

This cable gland is necessary to ensure the protection degree of the electric cubicle and

to protect its components from dust from the environment.

Local regulations remain applicable if they are stricter than the values proposed below.

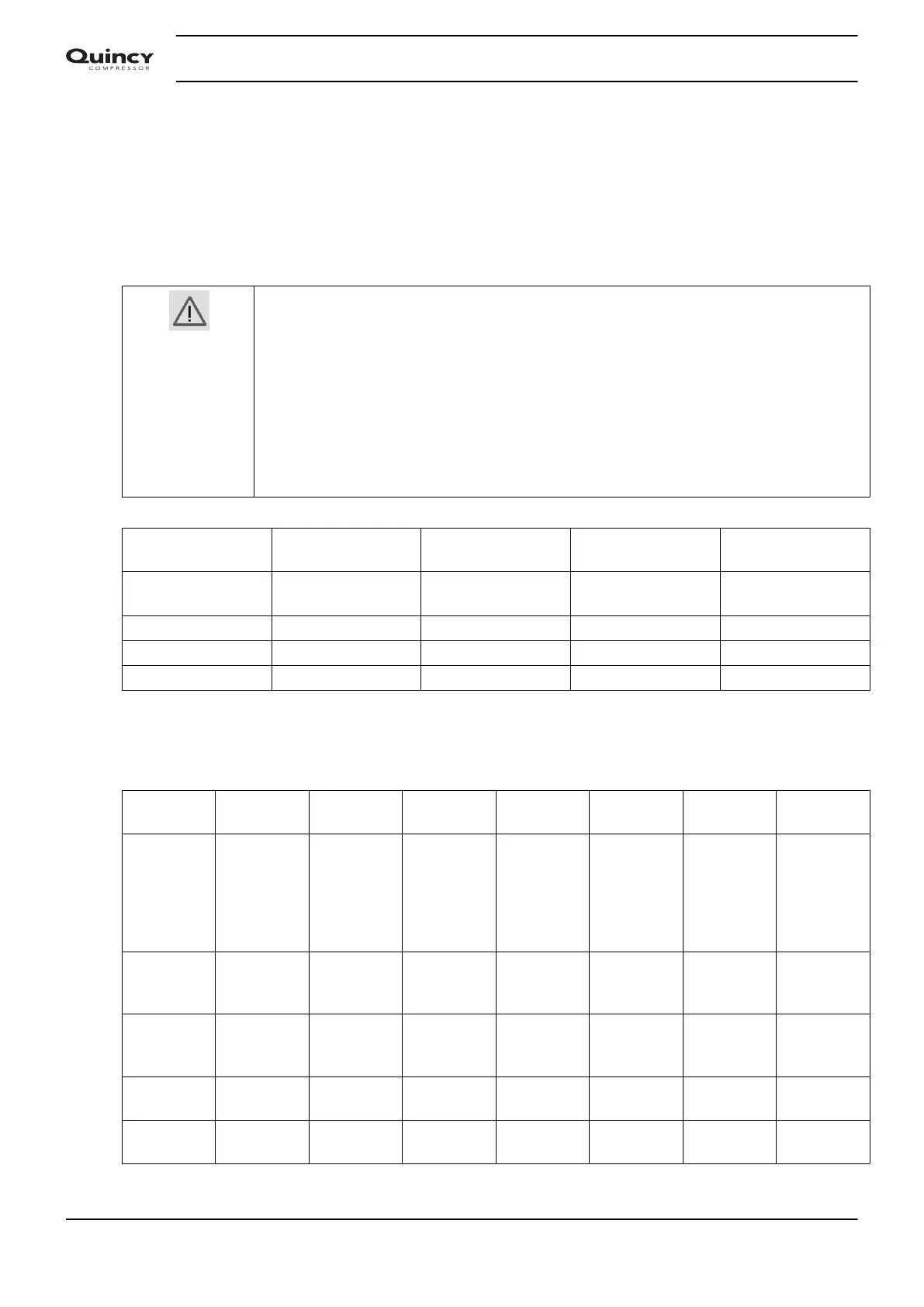

Power variant 7.5 kW

10 hp

11 kW

15 hp

15kW

20 hp

Frequency

(Hz)

Voltage

(V)

Cable Size Cable Size Cable Size

UL/cUL

60 208–230–460 AWG8/AWG10 AWG6/AWG10 AWG4/AWG8

60 575 AWG12 AWG10 AWG10

9.2 Settings for overload relay and fuses

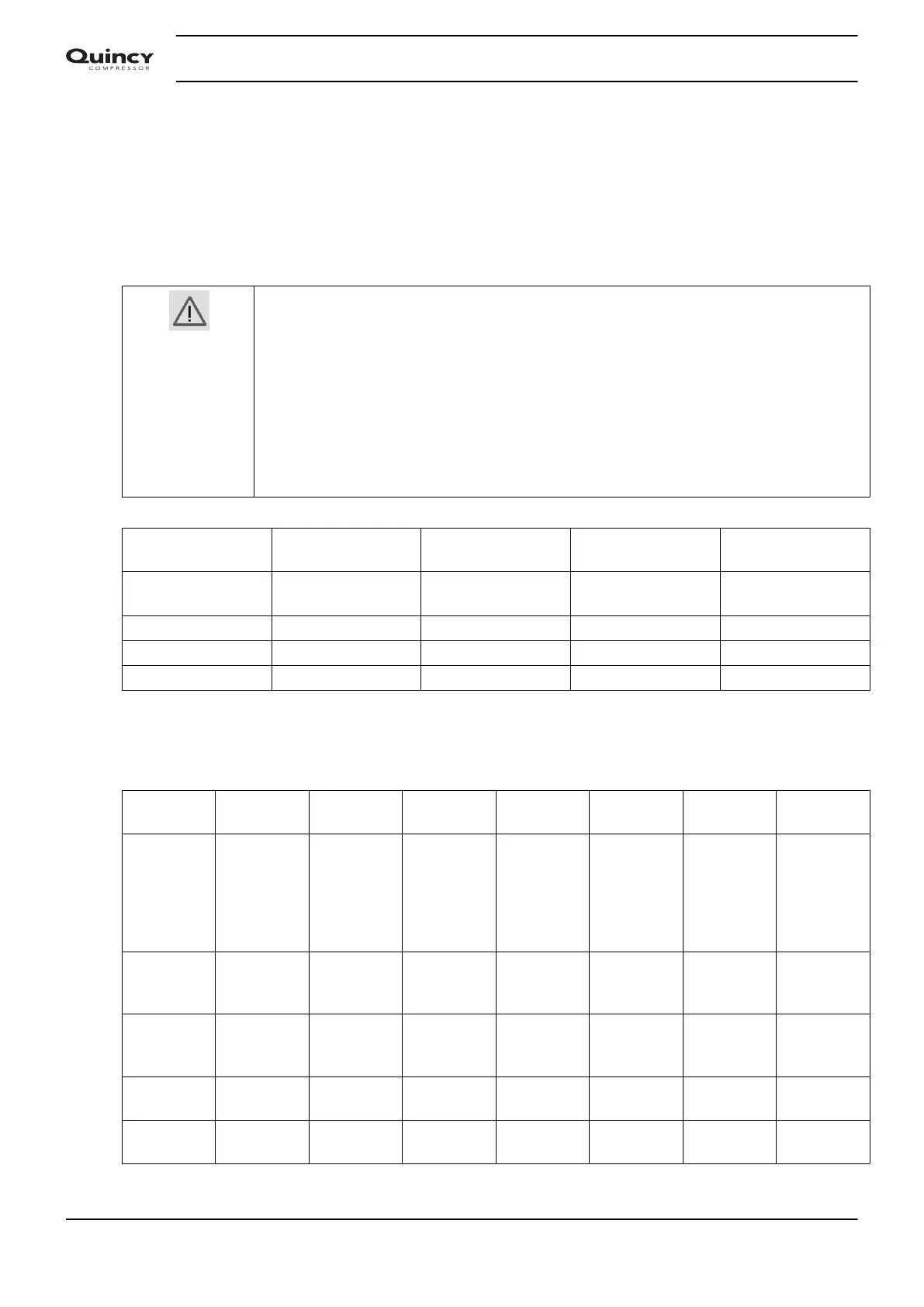

7.5 kW

10hp

11 kW

15hp

15 kW

20hp

Frequency

(Hz)

Voltage

(V)

UL/cUL

Setting

overload

relay FM1

(A)

Main fuses

(class J or

RK) + Disc.

switch size

>= 1.25 x

FLA

Setting

overload

relay FM1

(A)

Main fuses

(class J or

RK) + Disc.

switch size

>= 1.25 x

FLA

Setting

overload

relay FM1

(A)

Main fuses

(class J or

RK) + Disc.

switch size

>= 1.25 x

FLA

60 DOL

208-230–

460

36.3-34.3–

16.9

50-45–25 A 48-45–22.5 60-60–35 A N/A N/A

60 YD

208-230–

460

N/A N/A N/A N/A 33.2-30–15 80-80–40 A

60 DOL

575

13 20 A 18.5 25 A N/A N/A

60 YD

575

N/A N/A N/A N/A 12 30 A

Instruction book

86 2920 7113 40

Loading...

Loading...