2012 2039 28 114

6.

Run the compressor loaded for a few minutes. Stop the compressor and wait a few minutes to allow the

fluid to settle.

7.

Depressurise the system by unscrewing filler plug (FC) just one turn to permit any pressure in the system

to escape. Remove the plug.

Fill the oil tank with fluid. The fluid level should be between the top of the sight glass (Gl) and the filling

point (FC). Tighten the filler plug.

8.

Reset the service timer: see Service menu.

7.4 Coolers

General

Keep the coolers clean to maintain their efficiency

Never use a high pressure water jet to clean the compressor

Instructions for air-cooled compressors

1.

Stop the compressor, close the air outlet valve and switch off the voltage.

2.

Remove any dirt from the coolers with a fibre brush. Never use a wire brush or metal objects.

3.

Cover all parts under the coolers.

4.

Next, clean with an air jet in the reverse direction to normal flow. Use low pressure air. If necessary, the

pressure may be increased up to 6 bar(e) (87 psig)

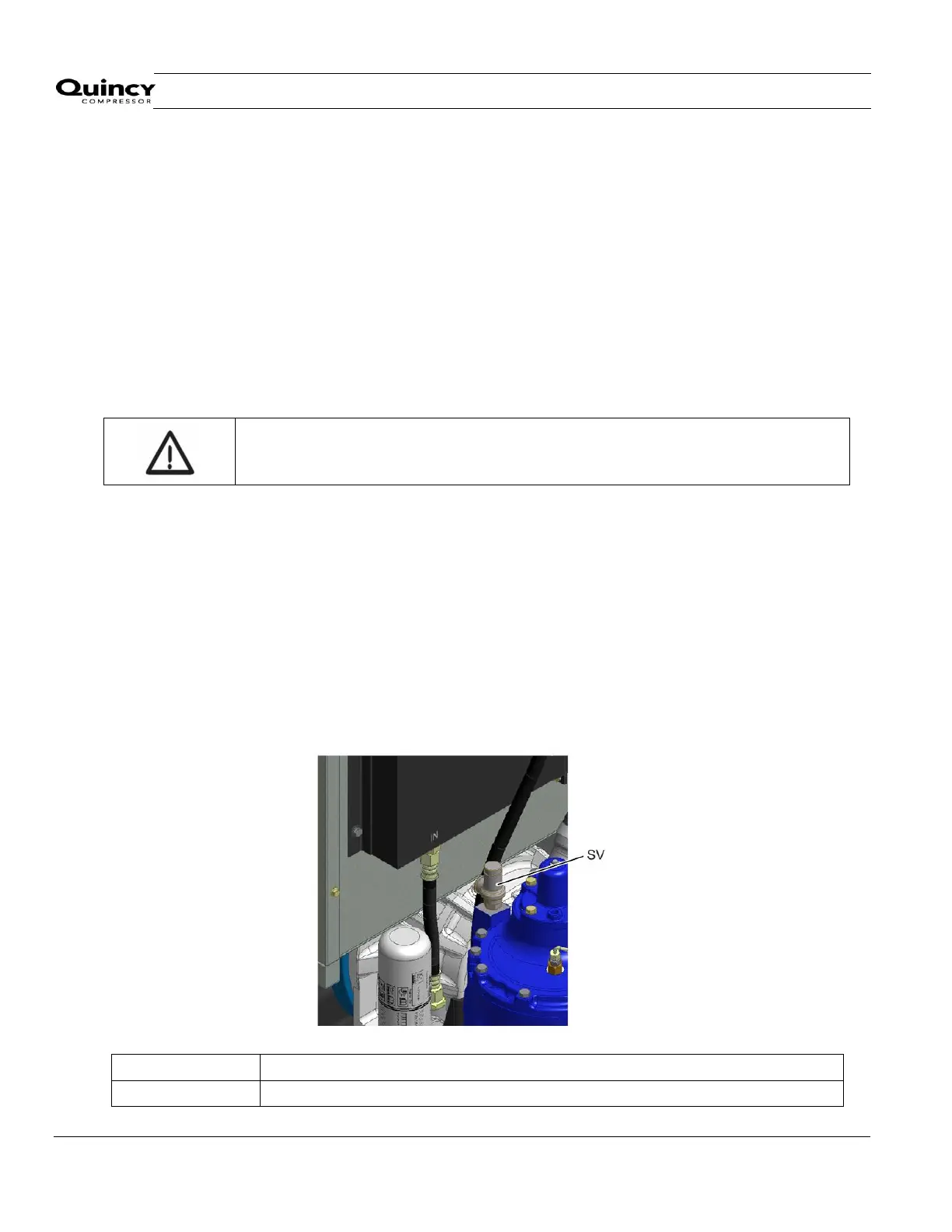

7.5 Safety valves

Location of safety valve

Loading...

Loading...