2012 2039 28 120

8 Problem solving

Before carrying out any maintenance, repair work or adjustment, press the stop button,

wait until the compressor has stopped, press the emergency stop button and switch off

the voltage. Close the air outlet valve and lock it, if necessary.

Depressurise the compressor by opening the oil filler plug one turn.

Open and lock the isolating switch.

The operator must apply all relevant Safety precautions.

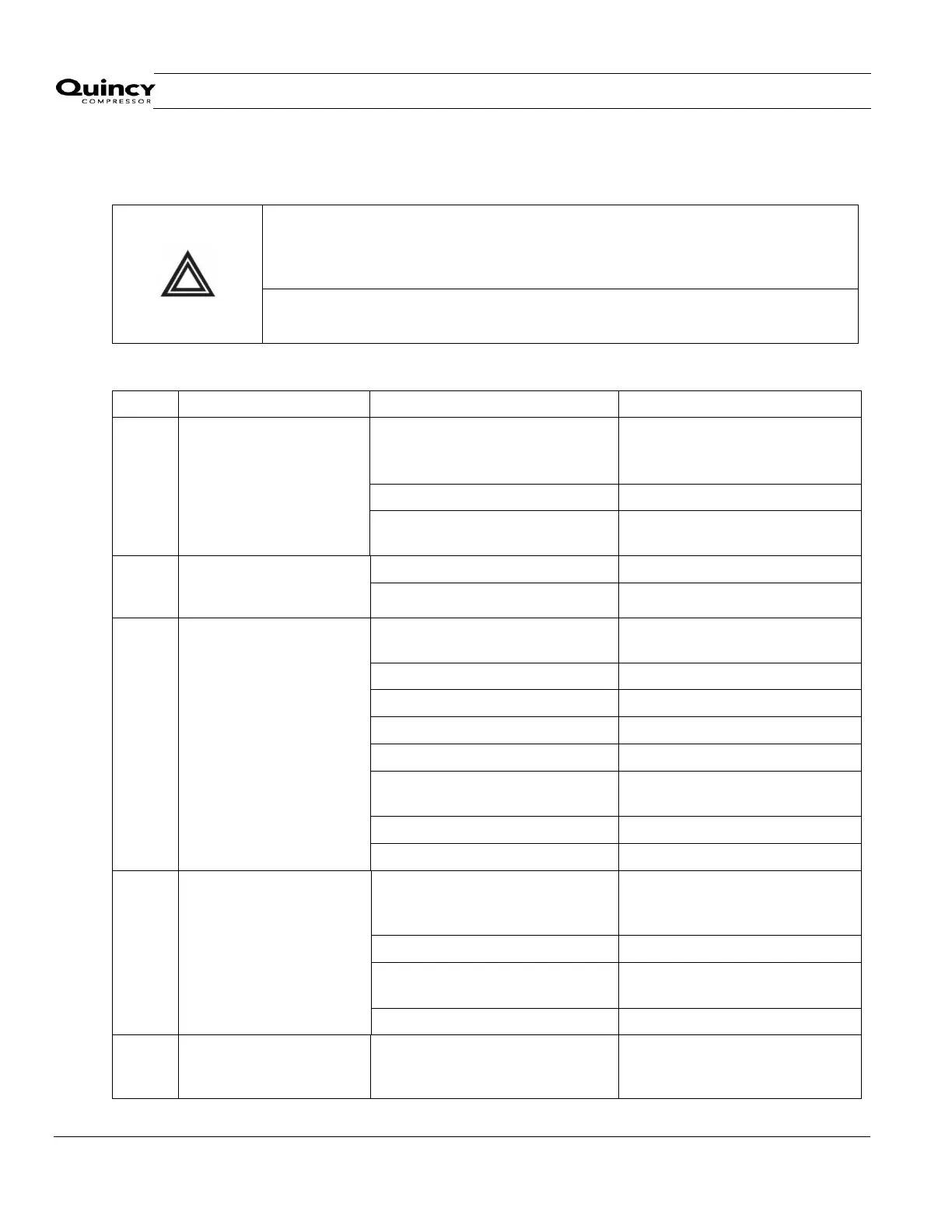

Compressor starts

running, but

does not

load after a delay time

Solenoid valve out of order

Inlet valve stuck in closed

position

Replace valve

Have valve checked

Leak in control air flexible

Minimum pressure valve leaking

(when net is depressurized)

Compressor does not

unload,

safety valve

blows

Solenoid valve out of order

Inlet valve does not close

Compressor air output or

pressure below normal

Air consumption exceeds air

delivery of compressor

Check equipment connected

Choked air filter element

Solenoid valve malfunctioning

Leak in control air flexible

Inlet valve does not fully open

Oil separator clogged

Air leakage

Have element replaced Have

leaks repaired

Excessive fluid

consumption; fluid carry-

over through discharge

line

Check for overfilling. Release

pressure and drain fluid to

correct level

Incorrect fluid causing foam

Have element checked. Replace

if necessary.

Excessive fluid flow

through air

inlet filter after

stopping

compressor

Check valve leaking or fluid stop

valve jammed

Replace defective parts. Replace

air filter element

Loading...

Loading...