20 Quincy Compressor

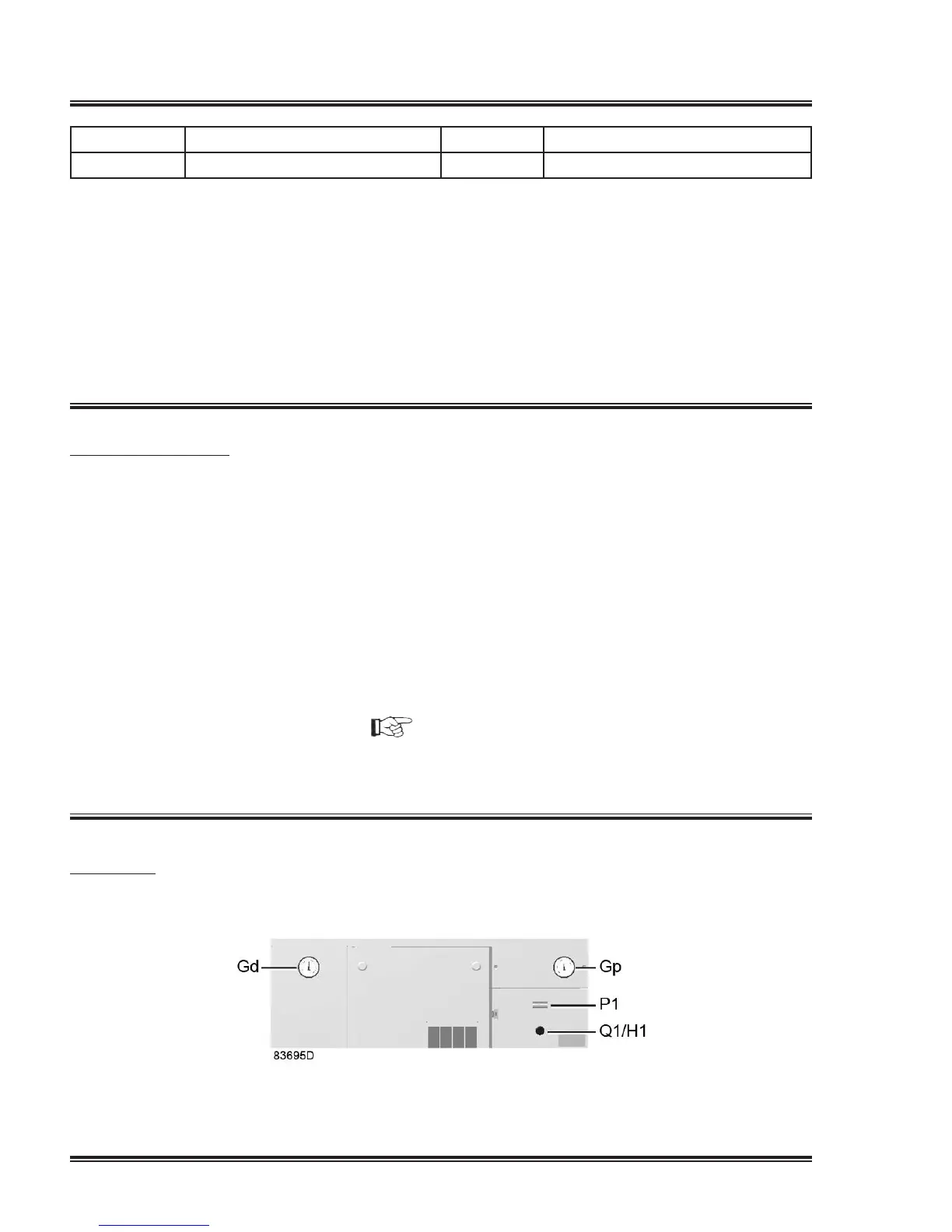

Gp Pressuregauge Q1/H1 On/off switch with lamp

P1 Hour meter Gd

Dewpointgauge

Procedure

1. Close the manual condensate drain valve(s) if present.

2. Opentheairoutletvalve(AV).

3. Switchonthevoltage.Lamp(H1)alights.

4. Rotateswitch(Q1)topositionI.

5. Themotorstartsandstopsautomaticallydependingontheairpressure.

6. Oncompressorsequippedwitharefrigerantdryer,thedewpointoftherefrigerant

dryer will be reached after a few minutes.

During operation

Procedure

1. Checkthepressuregauge(Gp)onthecontrolpaneltocheckthepressuresetting.

2. Oncompressorswithabuilt-inrefrigerantdryer,checkalsothetemperaturegauge

(Gd)onthecontrolpaneltocheckthedewpoint.

Checkthatcondensateisdischargedregularlybytheautomaticdrainofthedryer.

Theamountofcondensatedependsontheoperatingconditionsoftheunitand

the humidity of the air.

Open the manual drain valve from time to time to remove eventual impurities (see

alsosectionPreventiveMaintenanceschedule).

3. Onreceivermountedcompressors,openthemanualdrainvalveoftheairreceiver

regularly to remove the water (specially in case of compressors without dryer). See

alsosectionPreventiveMaintenanceschedule).

NOTICE!

The dew point will deviate from nominal when the nominal conditions are exceeded.

If the dew point remains too high or unstable, consult section Problem solving.

Stopping

Control panel

Loading...

Loading...