Section VII - Problem solving

34 Quincy Compressor

Attention

1. Beforecarryingoutanymaintenance,repairworkoradjustment,switchoffthe

voltage.

2. Openandlocktheisolatingswitchtopreventanaccidentalstart.

3. Isolatethecompressorbyclosingtheoutletvalve.

4. Depressurizethesystembyopeningthedrainvalve(s).

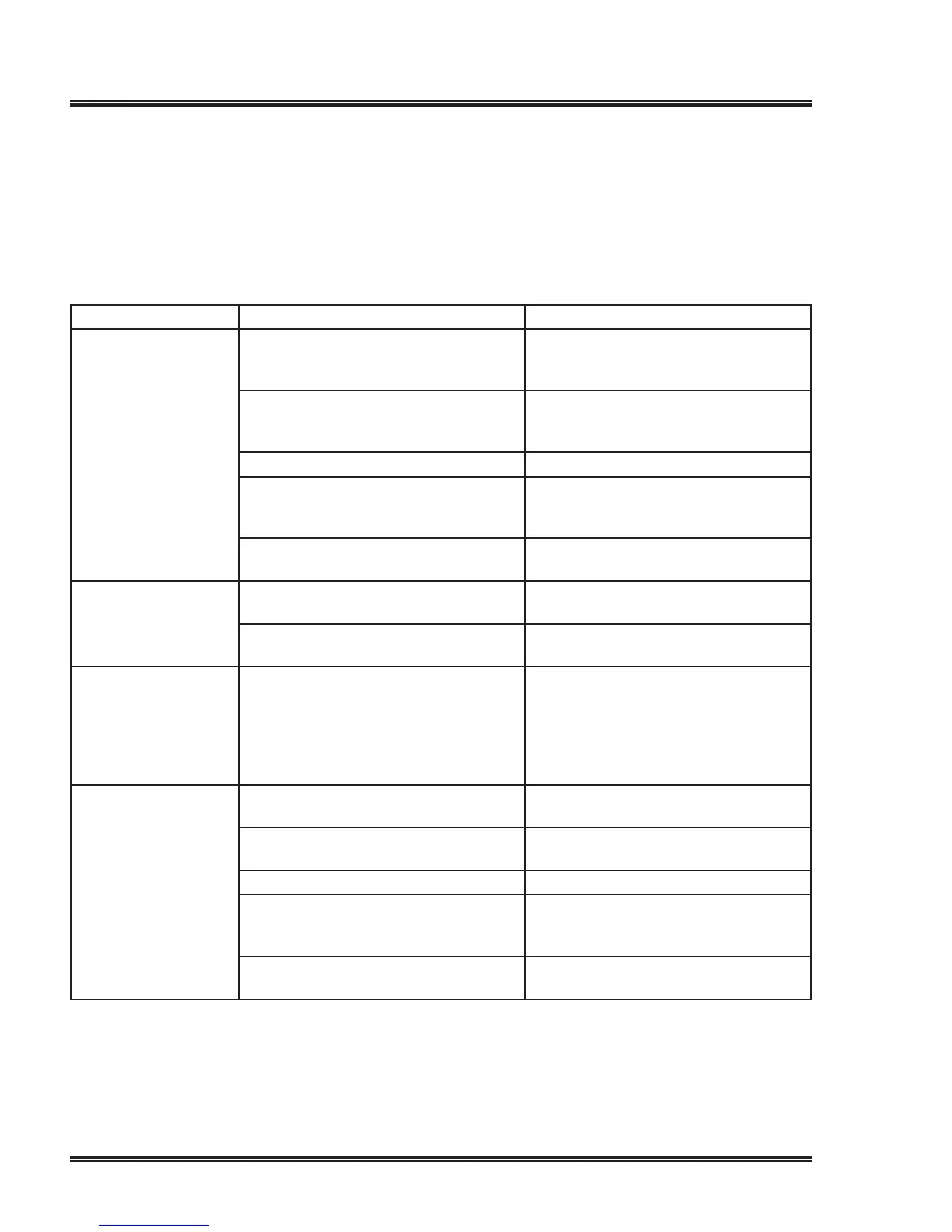

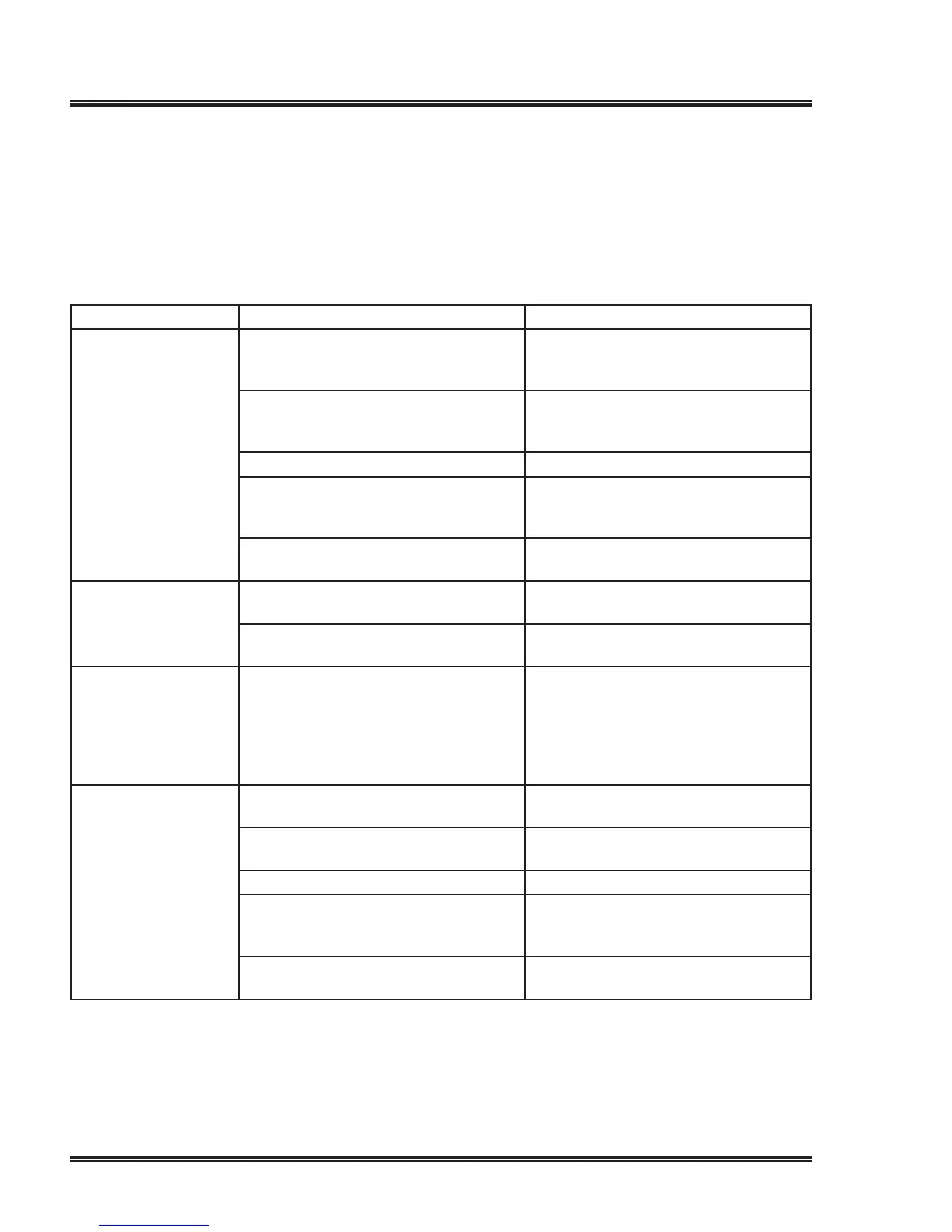

Compressor

Condition Fault Remedy

Thecompressor

does not start.

Pressuretoohigh.

Compressor will start again

when the pressure drops to the

starting pressure.

On/off switch (Q1)

malfunctioning or loose

connection

Have electrical connections

checked.

Testswitch.Replaceifnecessary.

Thermaloverloadofswitch(Q1) Restart after cooling down.

Switch(TSHH)openormotor

protectionrelay(F21)tripped

Wait for switch to cool down.

Replace switch if necessary.

Resetoverloadrelay(F21).

Airpressureswitch(PS)outof

order

Testswitch,replaceifnecessary.

Thecompressor

does not stop

and/or safety

valve blows.

Airpressureswitch(PS)opens

too late or not at all.

Readjust switch, replace if

necessary.

Safetyvalve(SV)openstoo

soon.

Have valve replaced.

Pressure

difference

between stopping

and starting

cannot be

adjusted

Airpressureswitch(PS)outof

order

Replace if necessary.

Compressor

capacity or

pressure below

normal

Airconsumptionexceeds

capacity of compressor.

Checkequipmentconnected.

Chokedairlter

Removeandchecklter.

Replace if necessary.

Safetyvalveleaking Replace valve.

Drivebeltsslipping.

Checkconditionofbeltsand

belt tension.

Correctorreplaceasrequired.

Compressor element out of

order

Consult the supplier.

Loading...

Loading...