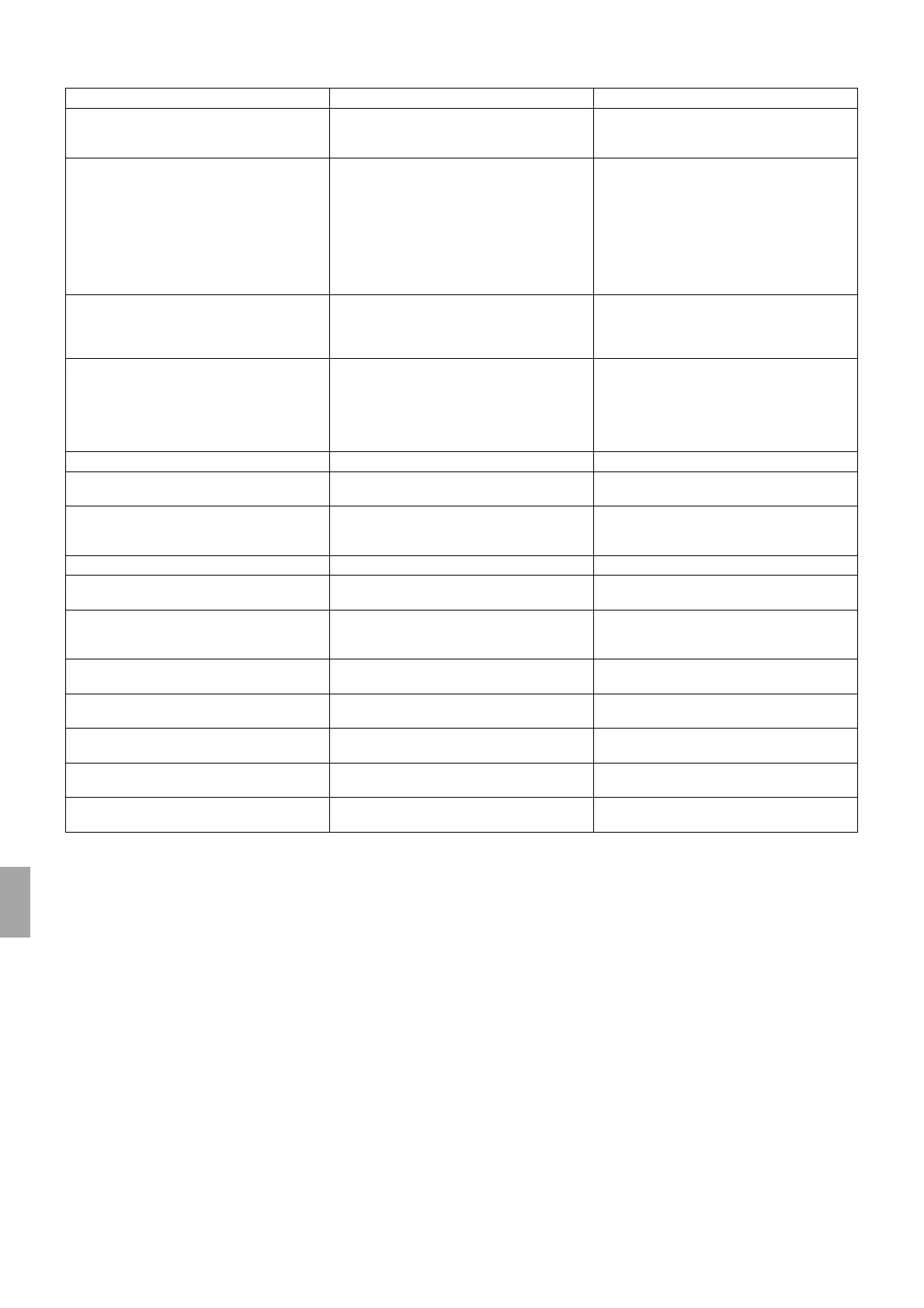

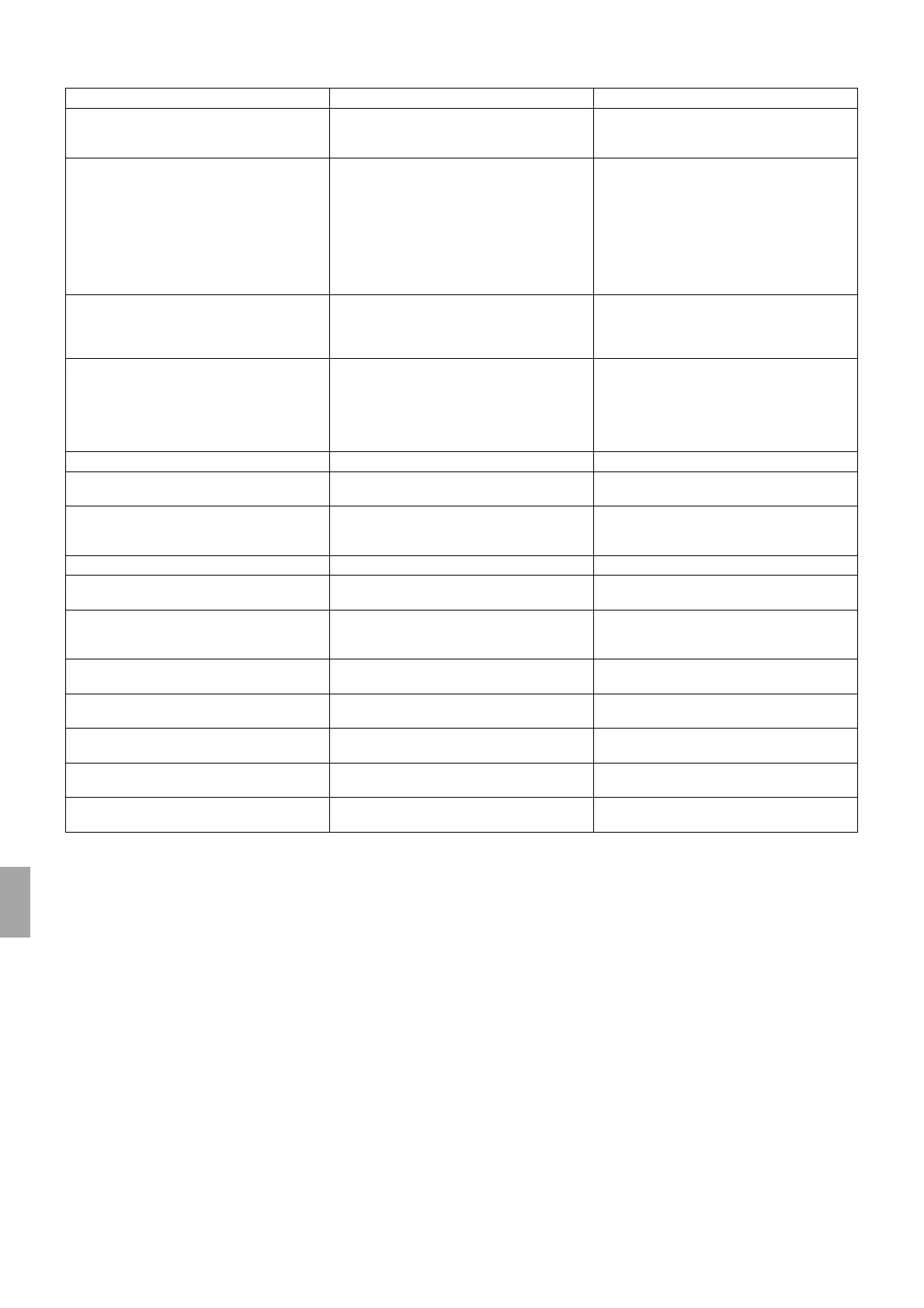

FAULT/CAUSERE/MEDY

18

FAULT CAUSERE MEDY

Burner does not light Burner safety cut-off button or burner relays

disconnected.

Push safety cut-off button. If burner does

not work properly after several attempts,

call service engineer immediately.

No ignition Short-circuited ignition electrodes

Ignition electrode gap too wide

Dirty or wet ignition electrodes

Ignition cable charred

Flame detector (photoresistor)

soiled or faulty

Blown insulator or ignition electrode

Faulty ignition transformer

Faulty automatic firing system

Adjust

Adjust

Clean

Determine cause and remove

Change ignition cable, clean if soiled.

Replace if faulty

Replace

Replace

Replace

Motor does not run Faulty condenser

Oil pump dirty or seized

Seized bearing

Faulty motor

Replace

Clean or replace

Replace motor

Replace motor

Pump does not deliver oil Damaged drive (clutch faulty)

Suction valve leaking or seized

Suction tube leaking

Air in suction tube

Filter dirty and clogged

Filter leaking

Replace

Clean or replace

Retighten screw connector

Bleed at pump

Clean

Replace

Incorrect burning Atomising pressure too low Increase pump pressure setting

Loud noises from pump Pump is sucking in air, vacuum in suction

tube too high

Tighten screw connector. Check tube for

cuts.

Irregular atomising Jet nozzle partially blocked

Nozzle worn out from over-use

Filter soiled

Replace jet

Replace

Clean

No oil-flow Jet hole blocked Replace jet

Oil flows out as soon as burner starts up Leaking magnetic oil pump valve

(or possibly dirty)

Clean or replace

Smell of gas Leaking tubes, armatures or burners Shut off gas taps at meter and at connecti

-

on to device. Contact customer service or

gas supply company immediately.

Smell of oil Leaking tubes, armatures or burners Check units for leaks. Repair leaking

sections or contact specialist repair firm.

Circulation pump does not run or cuts off Loose cable clamp or bridge

Faulty condenser

Tighten all clamp screws

Replace CO

2

value too low Air intake incorrectly set

Leaking flue pipe

Check combustion chamber settings

Seal flue pipe

Flue gas temperature too high Dirty boiler

Chimney draught too strong

Clean

Have draught interrupter installed

Flue gas temperature too low Burner capacity incorrect or burner incor

-

rectly adjusted

Have burner correctly adjusted

For all the faults* mentioned above, and for any others that may occur, it is advisable to call in a qualified person, and to entrust any ne

-

cessary repairs to a specialised firm only.

* Please keep the designer of the unit informed of any faults

Loading...

Loading...