f) Set storage charging pump switch (and circuit No. 2

heating pump, with SP 1.2) to

auto: if a rapidomatic S, 2 SM, 3 SM, Z 2.3 SM, Z 3.3

SM

heat regulator is in operation.

man: if running without rapidomatic heat circuit con-

trol, with incorrect working of control or when

running exclusively with RTU room dial

thermostat.

g) Set burners according to manufacturer’s instructions,

taking into account boiler capacity and the specified

combustion values.

h) Allow unit to heat up.

i) Check that all control, regulating and safety devices are

functioning properly and correctly adjusted.

j) If water level in unit is low, refill with water when boiler

has cooled down.

k) Train operator(s) in correct use of the unit.

10. Operation

See installation instructions for corresponding control pa

-

nel or regulator.

10.1 Taking out of service

Disconnect at main switch.

Shut off oil or gas supply.

10.2 Danger of frost damage

If heating operation is interrupted for long periods during

winter, the whole heating system – including the boiler –

must be completely emptied of water. Check when empty

-

ing that the drain tap does not become blocked with dirt.

The drain tap must remain open until the unit is refilled.

11. Care and maintenance

According to DIN 4755 and DIN 4756, all oil- or gas-fired

appliances must be inspected at least once a year for

correct and economical operation, and for safety, by a

person appointed by the system designer or other qualified

person. Combustion values are to be checked and, if

necessary, readjusted. It is advisable to take out a main-

tenance contract.

The boiler-room should be clean, dry and ventilated. The

boiler should be cleaned at certain intervals. Cleaning

regularity depends on fuel consumption, but should take

place at least at the start of each cold season.

11.1 Flue cleaning

Disconnect at main switch.

Remove front jacket.

Loosen nuts on burner door and lift door open.

Pull out radiation converter.

Clean combustion chamber and flue draughts with

a cleaning brush.

Fig. 15 cleaning boiler with a cleaning brush

Remove flue gas collector cleaning access cover and

cleanflue gas collector.

Replace cleaning access cover.

Clean remains of burnt fuel from boiler.

Replace radiation converter.

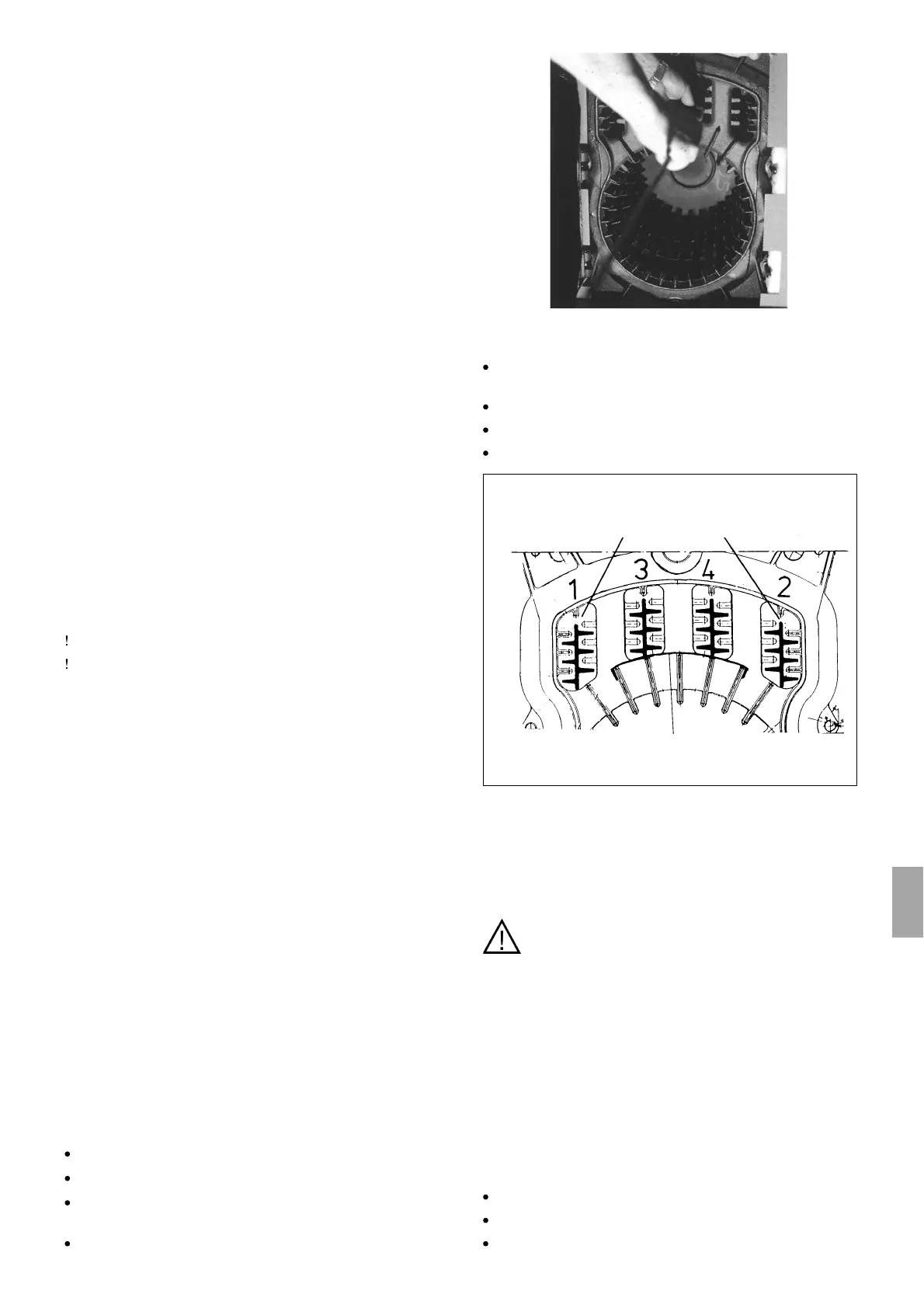

Fig. 16

The radiation converters are identified with numbers. This

identification number must face forwards when installing.

Insert radiation converters in flues according to identificati

-

on number as in Fig. 16.

NB!

The radiation converters are easily inserted. Do not

use undue force!

Note:

The number of radiation converters depends on boiler size

(see technical data table, chapter 7).

Flue baffle plates are installed with F 110/3 NT and F

110/4.1 NT only.

Some or all of the radiation converters can be removed for

purposes of controlling flue temperature with certain chim

-

ney configurations.

Shut burner door and tighten nuts.

Replace front jacket.

Reconnect at main switch and check combustion values.

Troubleshooting

17

F 110 NT front section

radiation converters

flue baffle plate

(F 110/3 + 4.1 NT only)

Loading...

Loading...