Installation

Page 7

Figure 9C. Honeywell MV Gas Valve.

ELECTRONIC IGNITION GAS VALVES

Figure 10. Location of Gas Pressure Adjustment.

PIPE SIZING FOR GAS CONNECTIONS

Table 5. Maximum Equivalent Pipe Length.

WATER CONNECTIONS

The heater requires water flow and positive pressure to

fire and operate properly. It must therefore be installed down-

stream of the discharge side of the filter pump. A typical

installation is plumbed as follows:

Maximum Equivalent Pipe Length

Natural Gas 1000 BTU/FT3 0.60

Specific Gravity @ 0.5 in. WC Pressure Drop

Propane Gas 2500 BTU/FT3 1.53

Specific Gravity @ 0.5 in. WC Pressure Drop

Input 1/2” 3/4” 1”

Model (KBTU) N P N P N P

130A 130 15 35 60 145 200 500

1. The inlet side of the filter is plumbed directly to the dis-

charge side of the filter pump;

2. The outlet side of the filter is then plumbed to the inlet of

the heater; and

3. The outlet of the heater is plumbed to the return line to

the pool or spa. The pump, filter and heater are thus

plumbed in series.

Plumbing from the heater back to the pool or spa must

not have any valves or restriction that could prevent flow

when the pump is operating.

Heater must be located so that any water leaks will not

damage the structure of adjacent area. PVC pipe may be

glued directly into optional or field-supplied header unions.

FLOW RATES

Table 6. Water Flow Rates.

*NOTE: When flow rates exceed maximum 100

GPM an external auxiliary bypass valve is required.

See External Auxiliary Bypass Valve section for

details.

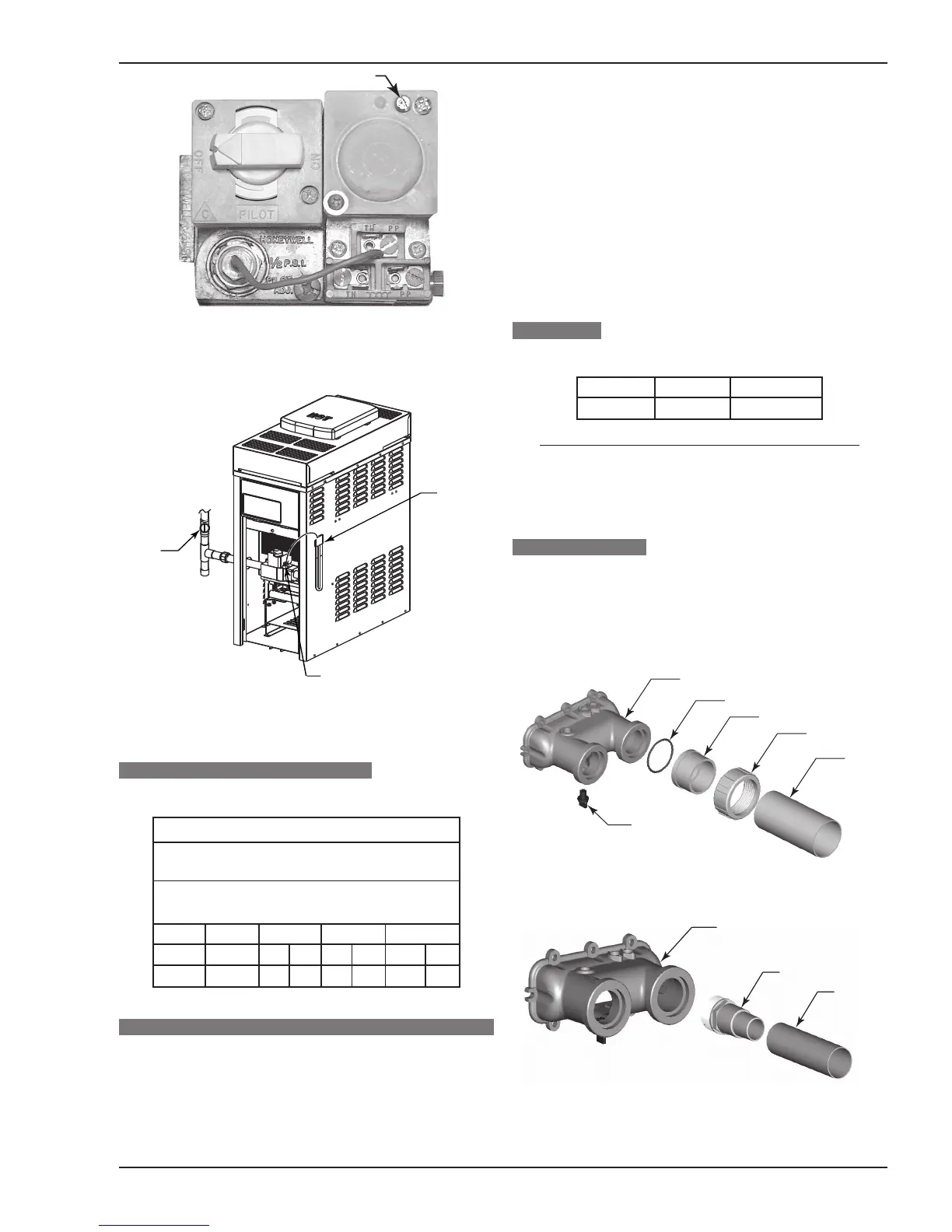

POLYMER HEADERS

Before attaching the optional 2-inch unions to the In/Out

header, make sure the O-rings are properly seated in the

grooves. Use AquaLube or equivalent non-petroleum-based

lubricant on the O-ring. Hand tighten the unions. Glue PVC

piping directly to the unions.

Figure 11. Optional In/Out Header for 2" Installation.

Figure 12. In/Out Header for 1-1/2" or 1-1/4" Hose Connection.

Loading...

Loading...