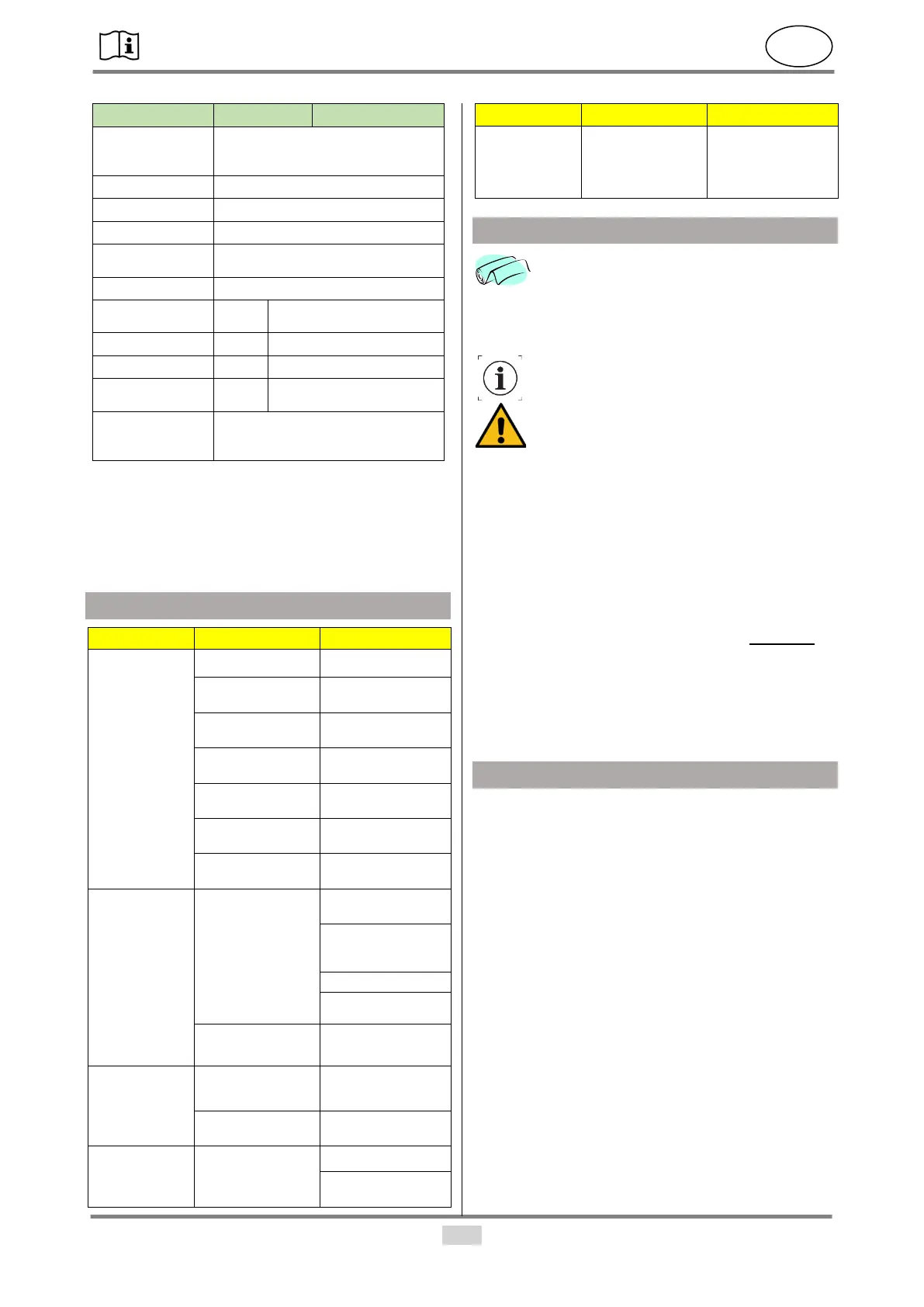

19. Cleaning and care

• The device can be cleaned using a

mild conventional cleaning and disinfecting

agent. After cleaning, wipe the device with clean

water and a cloth and then wipe it dry with a clean

cloth.

Maximum cleaning temperature of 35

C

must be observed!

The device must not be cleaned in an

automatic cleaning unit!

• Do not use scouring or cleaning

agents (read and observe the product information!)

that contain aggressive solvents (acids, benzene,

thinners) or stiff cleaning tools (brushes).

• Otherwise, this may result in damage to the metal

surface or deposits on the metal parts and other

materials.

Emergency lowering

• The emergency lowering mechanism must not be

treated with oil, grease or other lubricant. This will

lead to malfunctions during the lowering process.

In case of a malfunction of the emergency lower-

ing, the device must be reset by a maintenance

service.

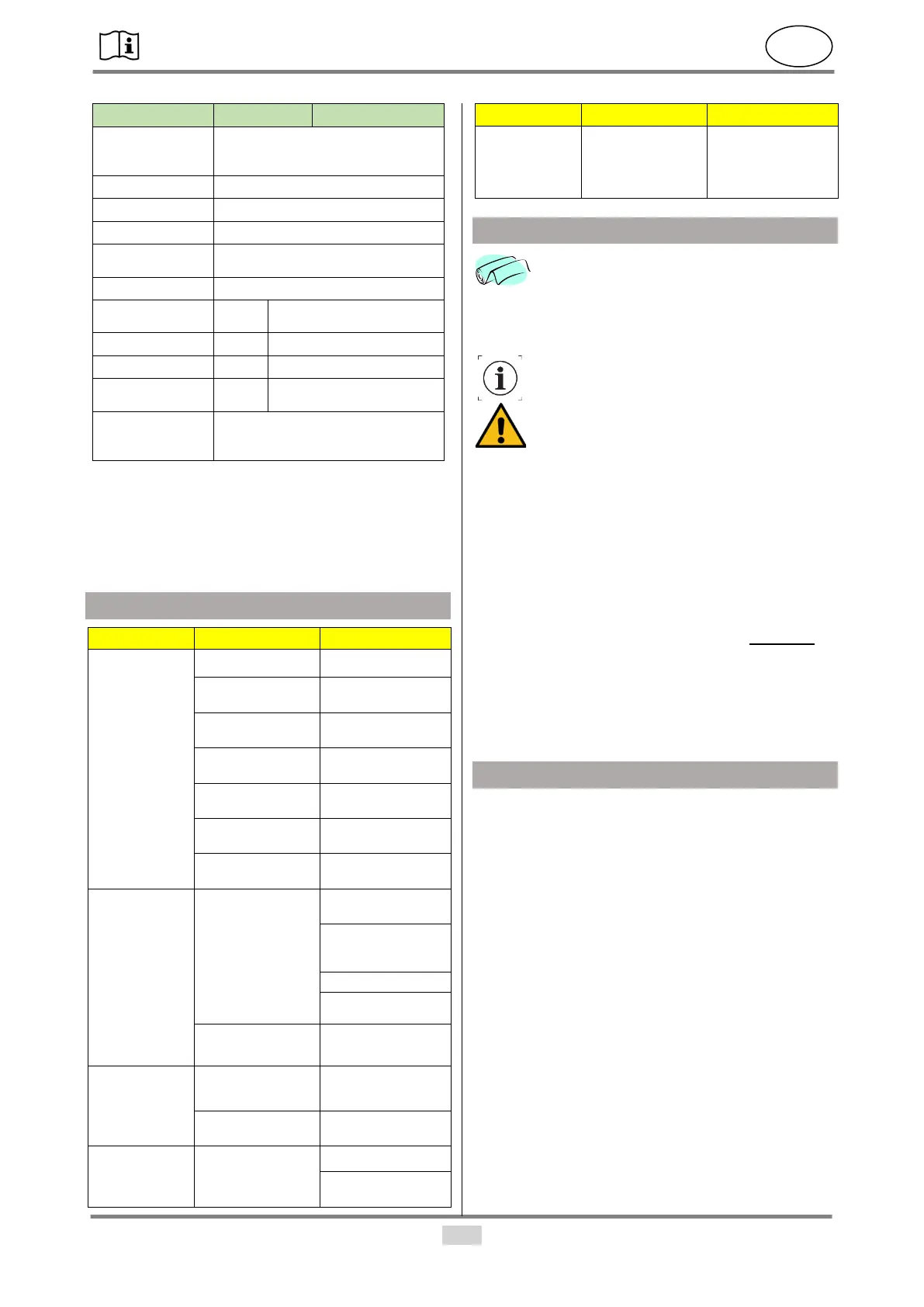

20. Maintenance

• Accidents may be caused by the late detection of

wear and/or improper use as well as irregular or no

maintenance.

• Please note that, for safety reasons and for pre-

venting accidents, the medical device must un-

dergo complete professional maintenance at least

• once a year. (Refer to the German MDR [Medical

Devices Act] and German MPBetreibV [Medical

Devices Operator Ordinance])

20.1. Scope of maintenance

• Please check at regular intervals:

• The intervals depend on the frequency of use and

the condition of the device.

• Devices for visible damage

(cracks, breakage, loose parts)

• All screw connections for tightness

(especially the castors and holder)

Loading...

Loading...