11

8. Assembly - cont.

Pan head screw

Tool holder

Fig.8.13

Fig.8.14

Mounting holes

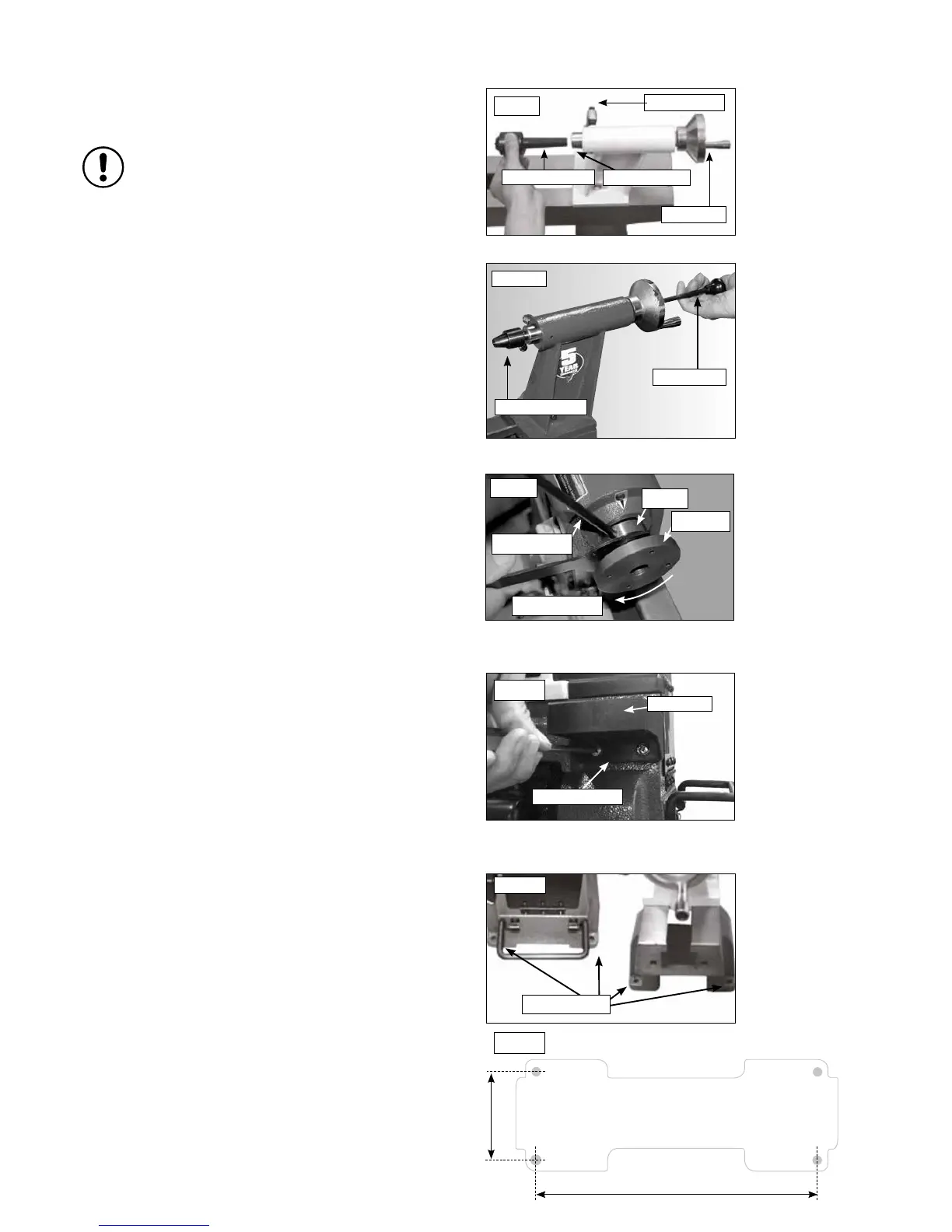

Secure Lathe to a Solid Work Surface

The lathe must be attached to a solid work surface or stand, not less than 25

mm thick. Four mounting holes are easily accessible at the base of the lathe,

Fig.8.14. Drill holes in the work surface, using a 13 mm or 1/2” drill bit,

following the measurements shown in Fig. 8.15.

Note: Use of the DML305/A Leg Stand is recommended.

To remove the revolving centre from the tailstock spindle insert the knockout

bar into the hole in the centre of the tailstock hand wheel and give the revolving

centre a sharp knock to dislodge it from the tailstock, see Fig 8.11.

Fitting the Faceplate to the Headstock

Thread the faceplate clockwise on to the headstock spindle. Place the

knockout bar in the circular hole in the spindle nose and hold firmly to

ensure the spindle does not turn. Now use the spindle wrench on the

faceplate collar to tighten the faceplate, turning clockwise, see Fig 8.12.

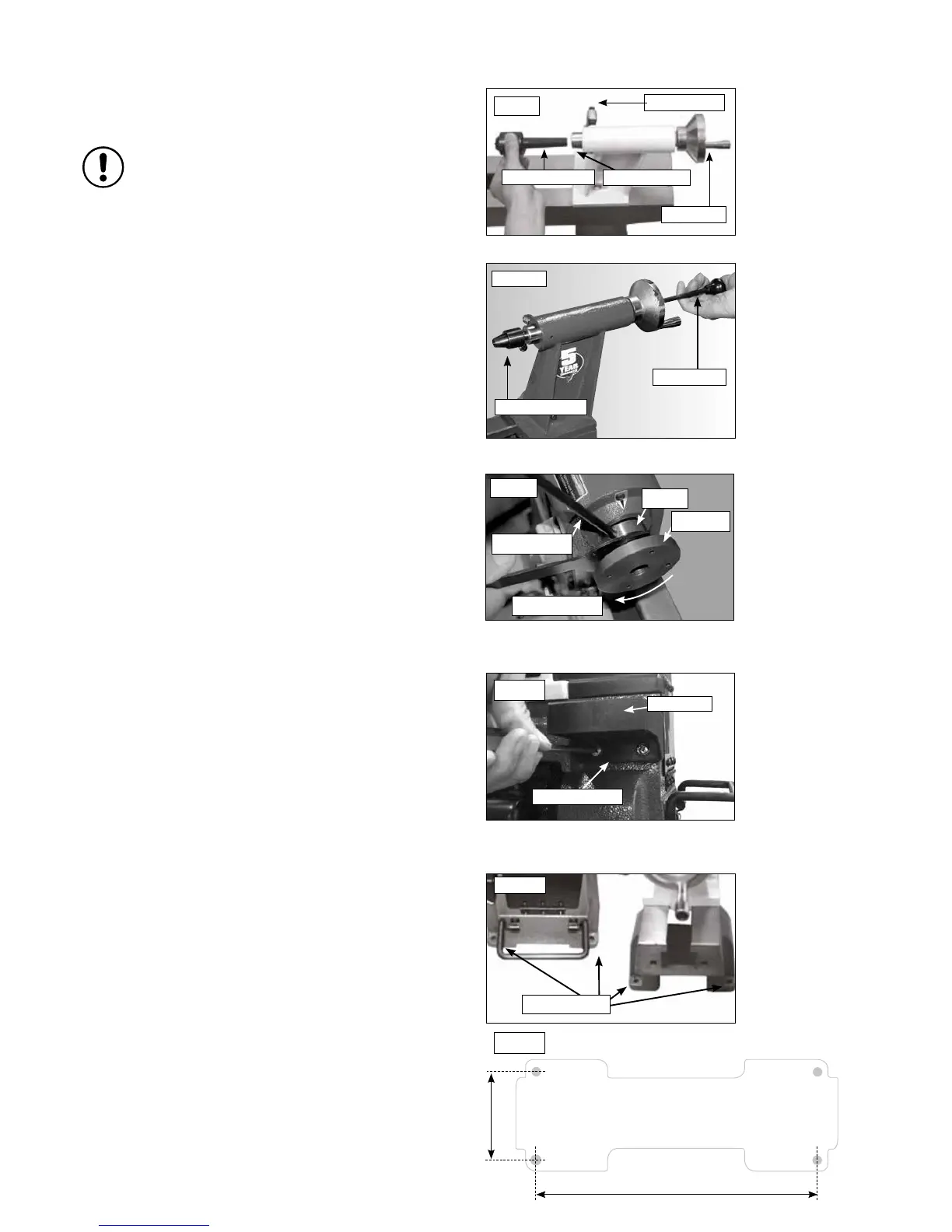

Fitting the Revolving Centre to the Tailstock

First ensure the locking handle is loosened then insert the revolving centre

into the tailstock spindle and tighten the locking handle, Fig.8.10.

Please note: Before inserting tapered attachments into the

headstock or tailstock spindle, always ensure that the taper

is clean and free of any waste material that may cause

misalignment or vibration. Always fully seat the taper by

tapping it into place with a wooden mallet.

Loading...

Loading...