20

12. Intended Use of the Lathe & Basic

Woodturning Instructions - cont.

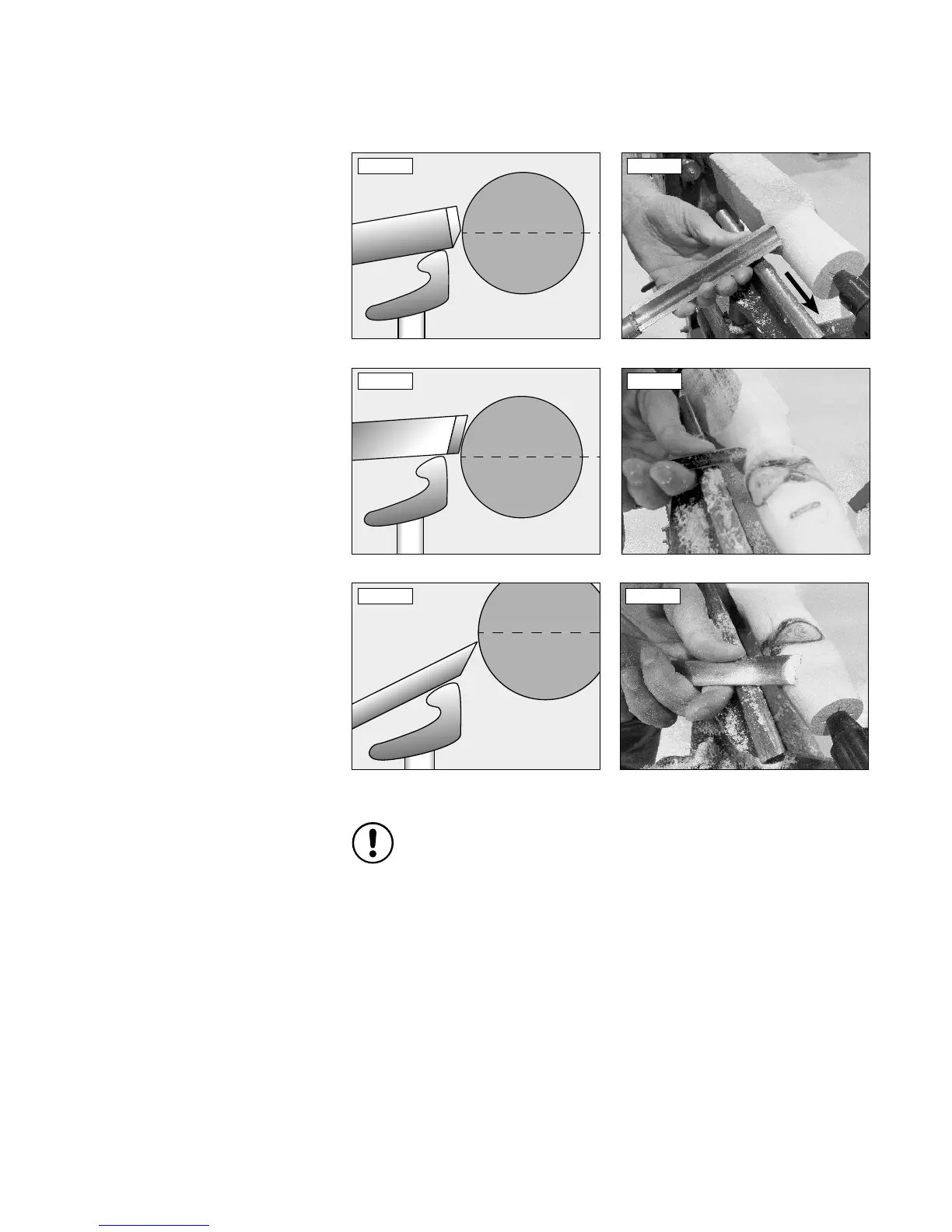

being used. When using a roughing gouge, the

cutting edge should come into contact with

the centre of the workpiece, see fig 12.6. If

using a skew chisel, the cutting edge should be

applied approximately 3/8" (10 mm) above the

centre height, see fig 12.7. A spindle gouge's

cutting edge should come into contact with the

workpiece approximately 3/8" (10 mm) below its

centre, see fig 12.8.

Using the Roughing Gouge

The first step when turning between centres is

invariably to 'rough out' the blank. This involves

taking a square section blank and paring it down

with a roughing gouge to a cylindrical profile,

ready to shape into the final piece. Roughing

gouges are usually sharpened to have the bevel

at a 45º angle. Using the tool rest to support the

blade, offer the blade to the workpiece at an

angle, see fig 12.9. When offering the rough-

ing gouge to the workpiece, the bevel should be

rubbing it, without cutting. To make a cut, gently

raise the handle of the tool in order to bring the

cutting edge into contact with the timber. Using

light passes, move the blade outwards towards

the same edge of the timber which the blade is

facing, fig 12.9. Never move the tool backwards,

as this introduces the risk of splintering the wood

and causing injury.

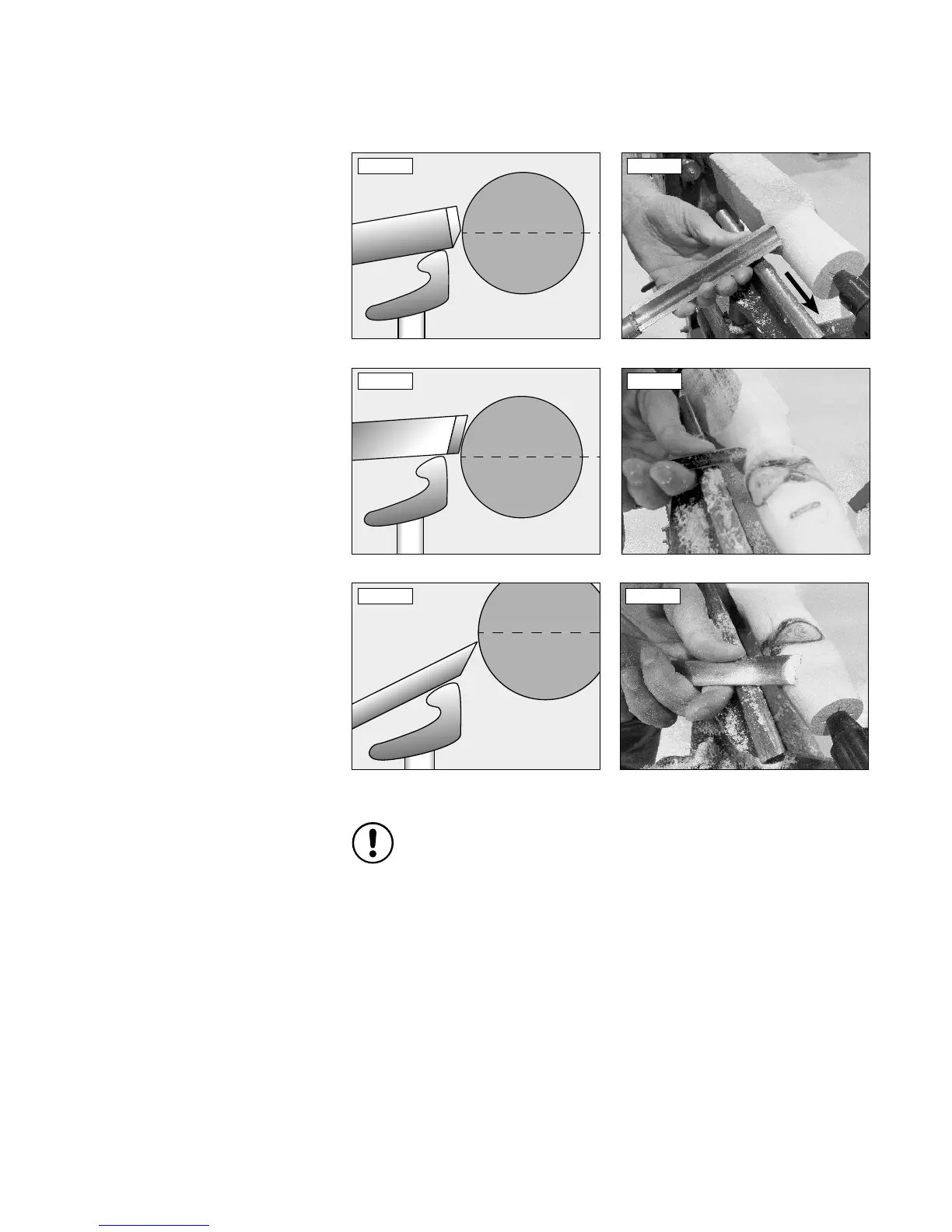

Using the Spindle Gouge

A spindle gouge is used to shape the final profile

of a spindle and is capable of finer work than a

roughing gouge. It is designed specifically for cut-

ting coves or valleys. The blade should come into

contact with the wood at just below the centre

line. Resting it on the tool rest, apply the blade

to the workpiece at an angle, see fig 12.10,

rubbing the bevel onto it. Raise the handle to

apply the cutting edge and make cuts. As with the

roughing gouge, use controlled and light passes,

trying to not remove too much wood at once.

Never attempt to use a spindle gouge for working

on bowls or hollow form work as the angle of the

cutting bevel of the gouge is too shallow and will

cause it dig in to the work piece or snatch the

tools from your hands.

Using the Skew Chisel

Skew chisels are available in both flat and oval

profiles. The curved profile is favoured by many

as it gives better results more easily. Skew chisels

are ideal for creating beads, refining the profiles

and can be used to create a final smooth finish to

the workpiece. The skew chisel should be applied

to the workpiece horizontally with the blade

resting on the tool rest, fig 12.11, again with

the bevel rubbing the workpiece and raising the

handle to take careful, controlled cuts.

Further Operations

The guidelines above give basic instructions

on some of the most common woodturning

procedures. There are a wide variety of special-

ised chisels and many complementary accessories

available for Record Power lathes which enable

a huge variety of work to be created. For further

instructions on more advanced safe and effective

woodturning, please seek professional training.

Fig.12.8

Fig.12.10

Fig.12.11

Fig.12.6

Fig.12.7

Fig.12.9

Speeds of the Lathe

To ensure the safest possible use of the lathe, it is important to understand which speeds are suited

to which tasks. In general, the slower speeds should be used for the initial turning and roughing out

of large pieces and the slowest speed should be used when large pieces are out of balance. This will

reduce the possibility of the workpiece being thrown from the lathe.

Medium speeds are ideally suited for general purpose work which doesn't place heavy loads on the

spindle of the lathes, for example when creating the profiles of spindles and some smaller

bowl turning.

The fastest speeds should be used only for small diameter work, where the size of workpiece is

relatively small and therefore poses a lower risk of causing damage. Extra care should be taken when

turning at the fastest speeds, using only a relatively light touch.

When sanding, care should be taken to not burn the operator's hands or the workpiece. It is recom-

mended to not exceed the speed used for the last turning operation. If in doubt, use a

slow speed.

Loading...

Loading...