10

Fig 8.7

Fig 8.9

Fig 8.10

8. Operation

Ensuring the teeth of the blade are pointing downwards, hook the end of

the blade to the lower blade holder as shown in Fig 8.6.

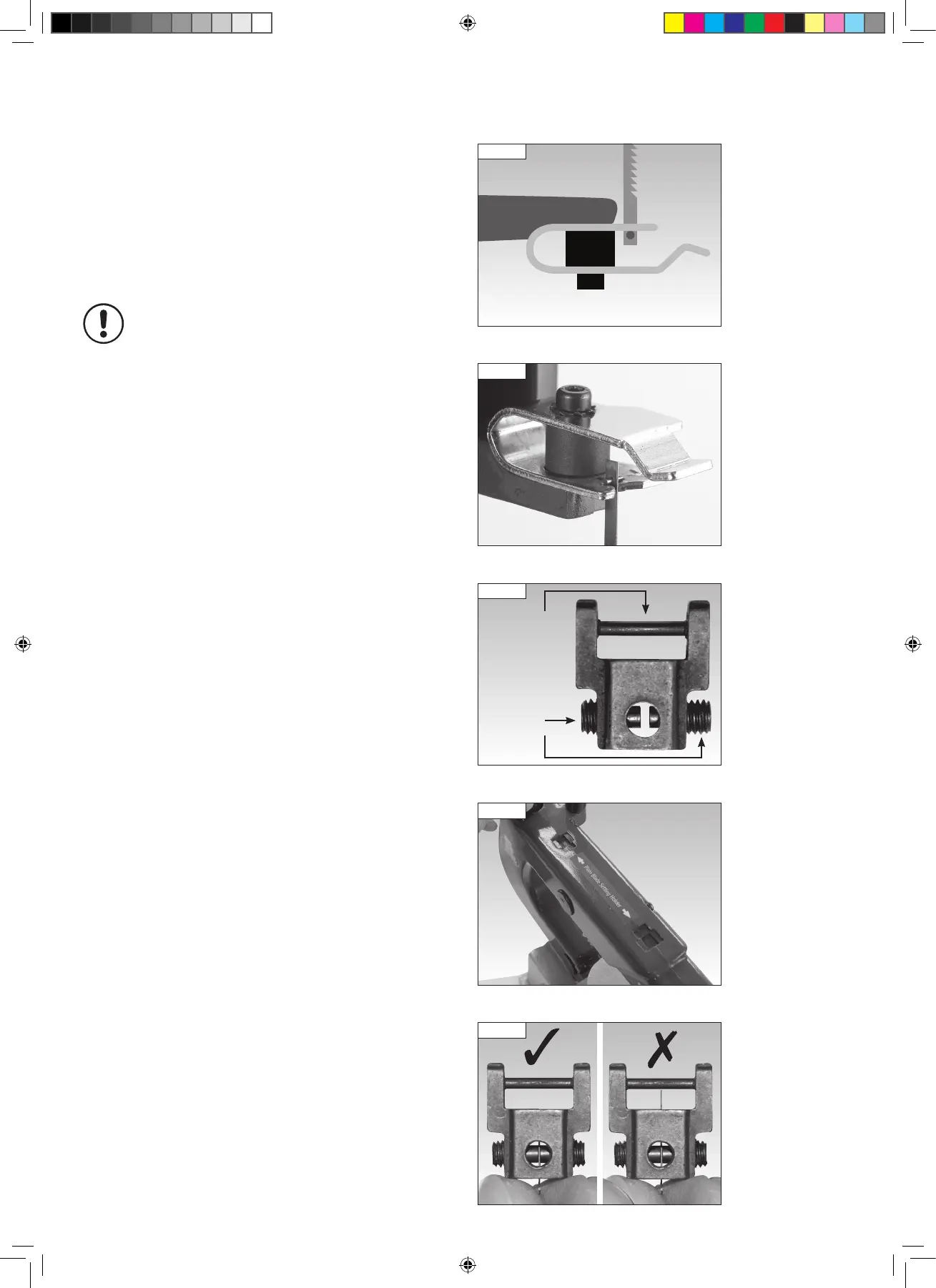

Apply gentle pressure to the upper blade holder to lower its position and

allow the top of the blade to be hooked in position on the blade holder as

shown in Fig 8.7.

To apply tension to the blade, turn the blade tension knob clockwise until

slight resistance is felt on the knob. Further tightening from this point is

now required - for most blade types and applications, a further half turn to

full turn of the knob is sufficient.

Please note: Over-tightening of the scrollsaw blade will shorten

the blade's life and may cause it to break.

Fitting Plain-End Blades

The SS16V is supplied with 2 plain-end blade adaptors. Each adaptor

features 2 blind set screws as shown in Fig 8.8 which are used to hold

the blade in place. The locating bars are used to attach the adaptors to the

blade holders on the machine.

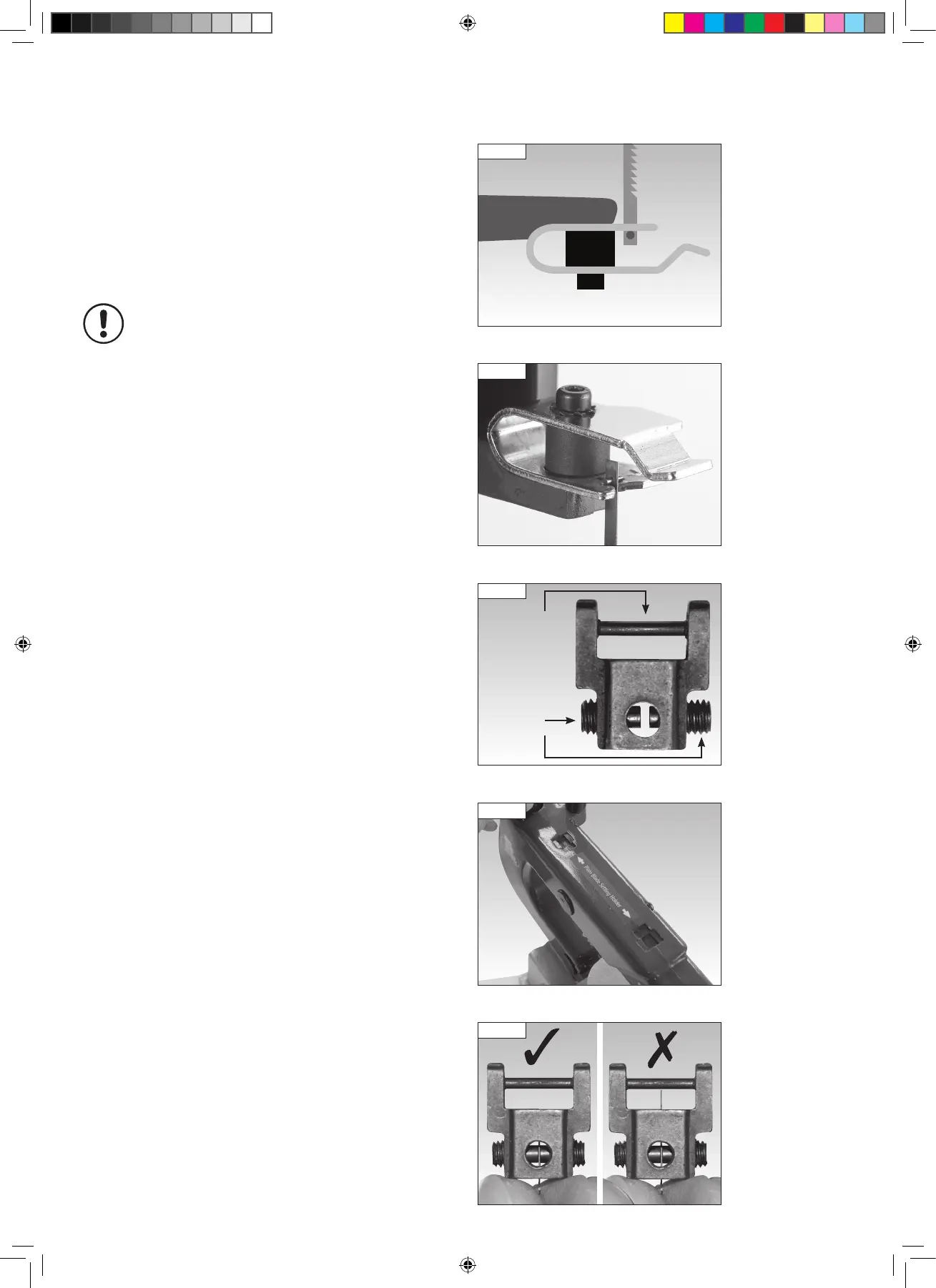

To ensure the blade adaptors are attached in the correct position on the

blade, the plain blade setting jig on the arm of the SS16V should be used as

shown in Fig 8.9.

To fit the blade to the adaptor, position one of the blind set screws to

protrude approximately halfway into the hole as shown in Fig 8.8 using

a 2.5 mm hex wrench. Retract the second blind set screw enough to allow

the blade end to be placed between them and tighten the second screw to

secure the blade end in place.

The end of the blade should not protrude from the main body of the blade

adaptor into the gap between the main body and the locating bar as this

would stop the blade holder of the machine from passing through the gap

to secure it in position, see Fig 8.10.

Fig 8.8

Blind set

screws

Locating

bar

Fig 8.6

Lower blade

holder

Pin-end

blade

SS16V Manual 4.0 (54100, 54101, 54102) 4.0.indd 10 10/09/2015 11:17

Loading...

Loading...