13

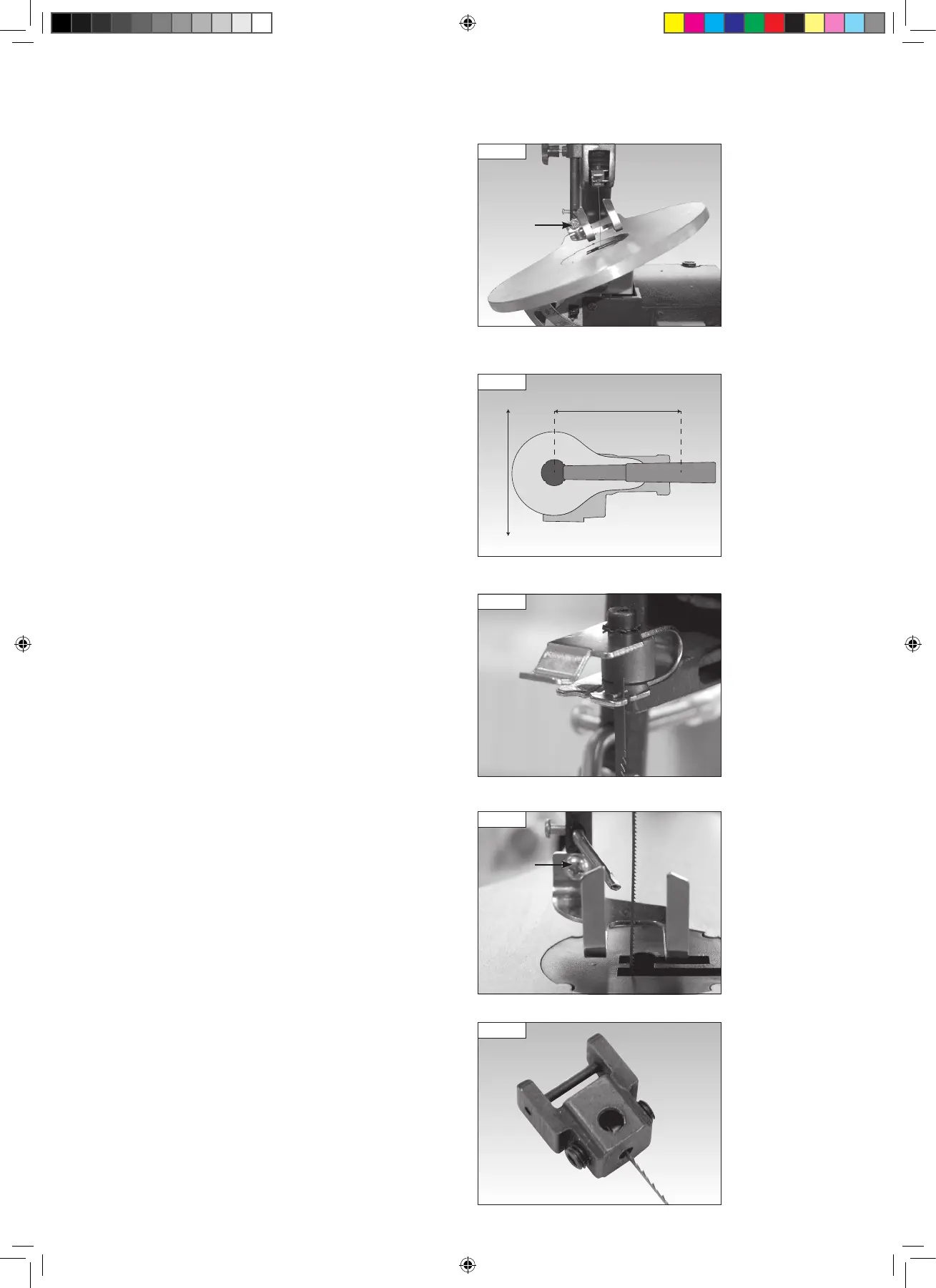

When cutting at angles, the drop foot should be tilted so it is parallel with

the table surface, allowing it to rest flush against the workpiece. To tilt the

drop foot, loosen the securing screw using a Phillips screwdriver, Fig 8.21,

tilt the foot so it is parallel with the table then re-tighten the securing screw.

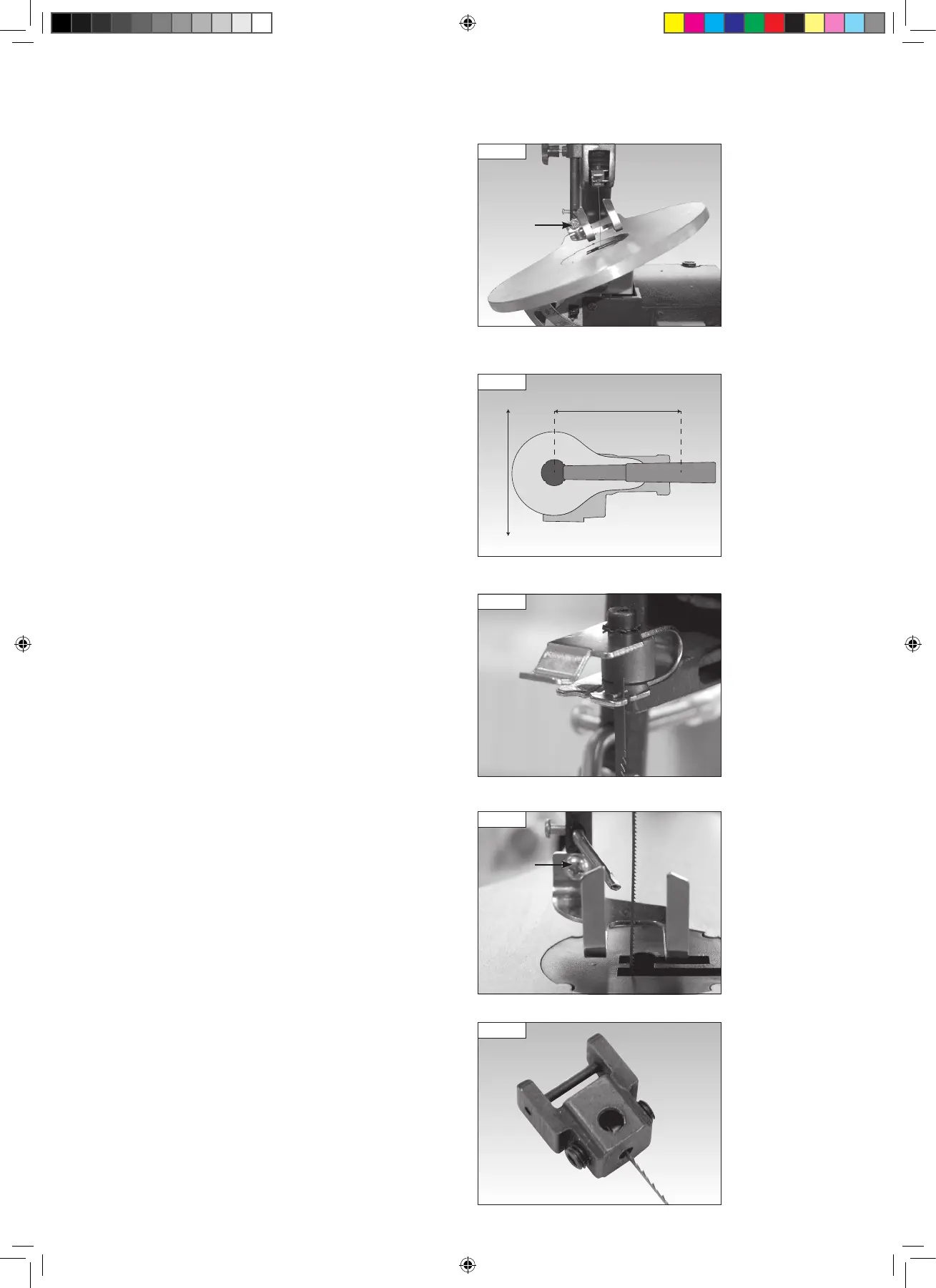

Cutting Workpieces Larger than 406 mm (16")

If the workpiece exceeds 406 mm (16") it may not be possible to cut into it

with the blade facing forwards, as shown in Fig 8.22.

To cut large workpieces, the scrollsaw blade can be position at 90º to the

machine arm, allowing the workpiece to pass freely from the right hand to

the left hand side of the machine as shown in Fig 8.22.

Fitting Pin-End Blades to the Scrollsaw at 90º

To fit pin-end blades to the machine at 90º follow the instructions given for

fitting the blade in the standard position but use the slots to the right hand

side of the blade holders as shown in Fig 8.23.

When fitting blades at 90º, the drop foot will have to be re-positioned so as

not to touch the blade. To do so, loosen the phillips head screw, re-position

the drop foot and re-tighten the screw as shown in Fig 8.24.

Fitting Plain-End Blades to the Scrollsaw at 90º

The plain-blade adaptors are supplied with their blind set screws installed in

the correct holes for accepting blades in the standard position. The adaptors

also feature 2 holes on the adjacent sides to these holes, see Fig 8.25.

Fig 8.23

Fig 8.25

8. Operation

Fig 8.22

406 mm depth of cut

Infinite depth of cut

Fig 8.21

Fig 8.24

Loosen

screw

to move

drop

foot

Loosen

screw

to move

drop

foot

SS16V Manual 4.0 (54100, 54101, 54102) 4.0.indd 13 10/09/2015 11:17

Loading...

Loading...