22

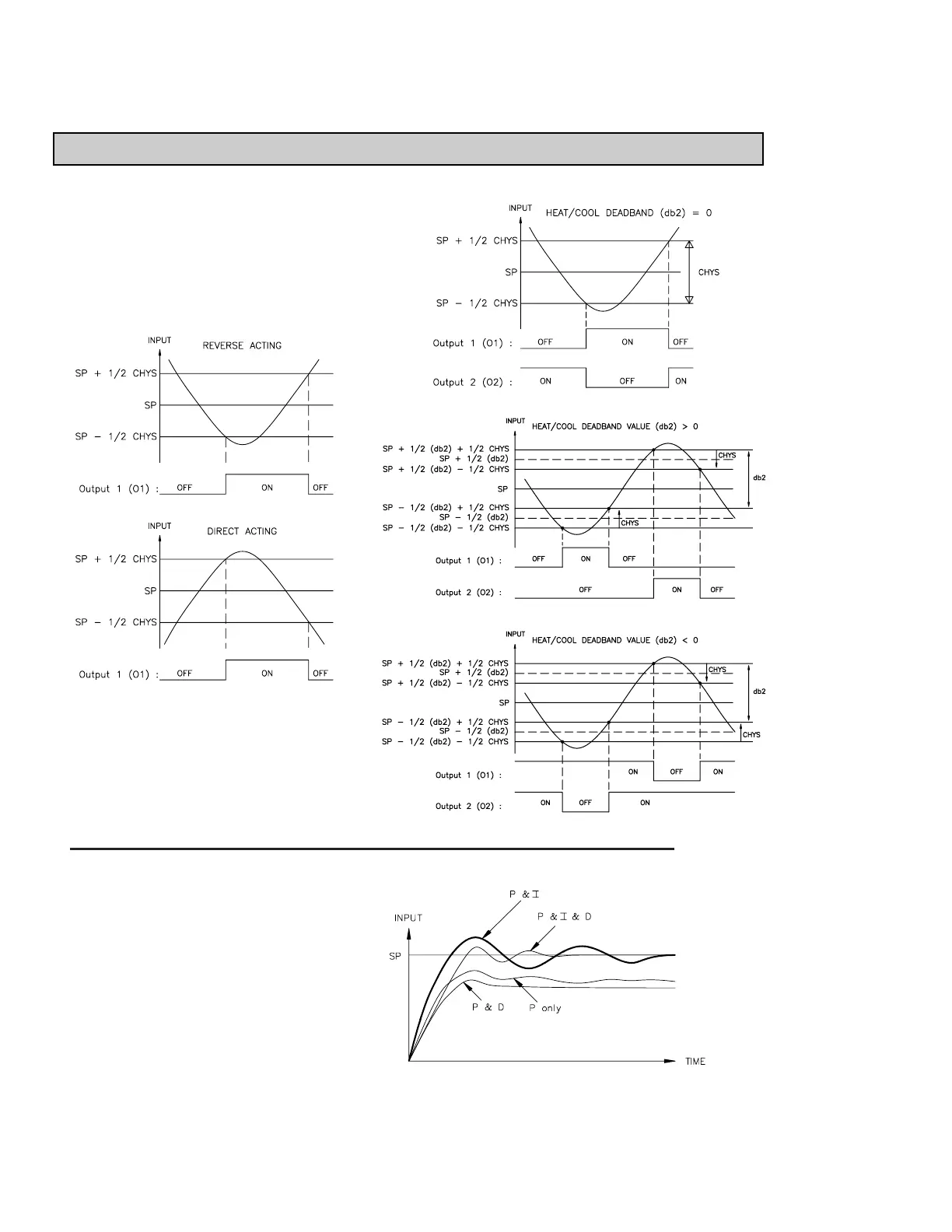

ON/OFF CONTROL

The controller operates in On/Off Control when the

Proportional Band is set to 0.0%. In this control mode, the

process will constantly oscillate around the setpoint value. The

On/Off Control Hysteresis (balanced around the setpoint) can be

used to eliminate output chatter. Output O1 Control Action can

be set to reverse for heating (output on when below the setpoint)

or direct for cooling (output on when above the setpoint)

applications.

ON/OFF CONTROL -

REVERSE OR DIRECT ACTING FIGURES

Note: CHYS in the On/Off Control Figures refers to the On/Off

Control Hysteresis (

4*?)) in parameter Module 2.

For heat and cool systems, O1 Control Action is set to reverse

(heat) and the Alarm 2 Action is set to cooling (O2). The

Proportional Band is set to 0.0 and the Relative Gain in Cooling

to 0.0. The Deadband in Cooling sets the amount of operational

deadband or overlap between the outputs. The setpoint and the

On/Off Control Hysteresis applies to both O1 and O2 outputs.

The hysteresis is balanced in relationship to the setpoint and

deadband value.

CONTROL MODE EXPLANATIONS

ON/OFF CONTROL - HEAT/COOL OUTPUT FIGURES

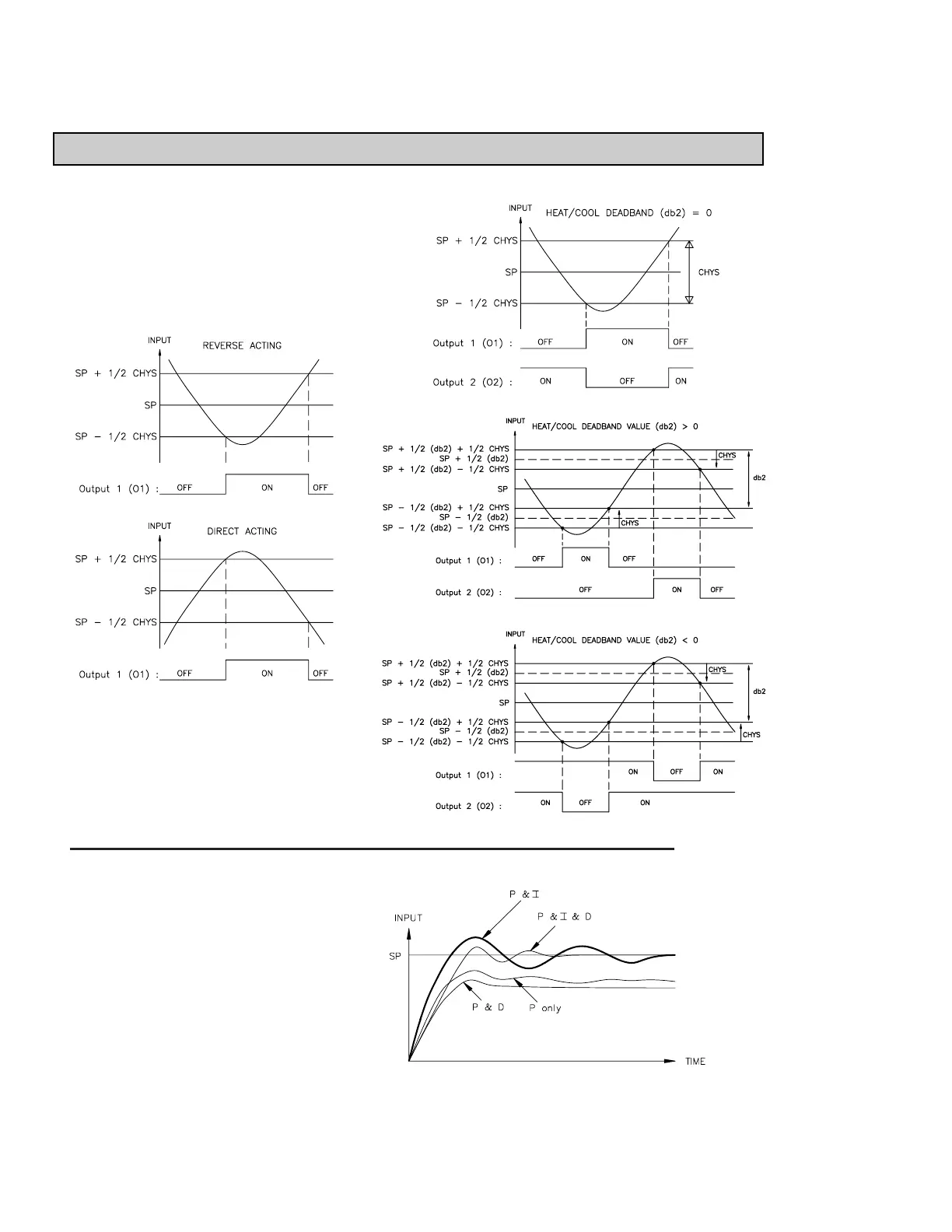

PID CONTROL

In PID Control, the controller processes the input and then

calculates a control output power value by use of a modified

Proportional Band, Integral Time, and Derivative Time control

algorithm. The system is controlled with the new output power

value to keep the process at the setpoint. The Control Action for

PID Control can be set to reverse for heating (output on when

below the setpoint) or direct for cooling (output on when above

the setpoint) applications. For heat and cool systems, the heat

(O1) and cool (O2) outputs are both used. The PID parameters

can be established by using Auto-Tune, or they can be Manually

tuned to the process.

TYPICAL PID RESPONSE CURVE

Loading...

Loading...