Regency

®

U39-10 ULTIMATE Direct Vent Freestanding Gas Stove | 27

27

|

installation

GAS PIPE PRESSURE

TESTING

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.45

kPa). Disconnect piping from valve at pressures

over 1/2 psig.

CONVERSION TO LOWER BTU RATING

THIS CONVERSION MUST BE DONE BY A QUALIFIED GAS

FITTER IF IN DOUBT DO NOT DO THIS CONVERSION !!

Natural Gas Conversion Kit 730-920

Contains:

Qty. Part # Description

1 904-240 Burner Orice #37 (Natural Gas)

1 918-034 Decal "Converted to 30,000 Btu"

1 918-033 Instruction Sheet

Propane Conversion Kit 730-922

Contains:

Qty. Part # Description

1 904-390 Burner Orice #52 (Propane)

1 918-034 Decal "Converted to 30,000 Btu"

1 918-033 Instruction Sheet

Additional Piece (pkg. with unit):

1 Log Bracket Restrictor

1. Shut off the gas and electrical supply.

2. Remove the safety screen - open the front

door. Carefully remove the logs and lava

rock.

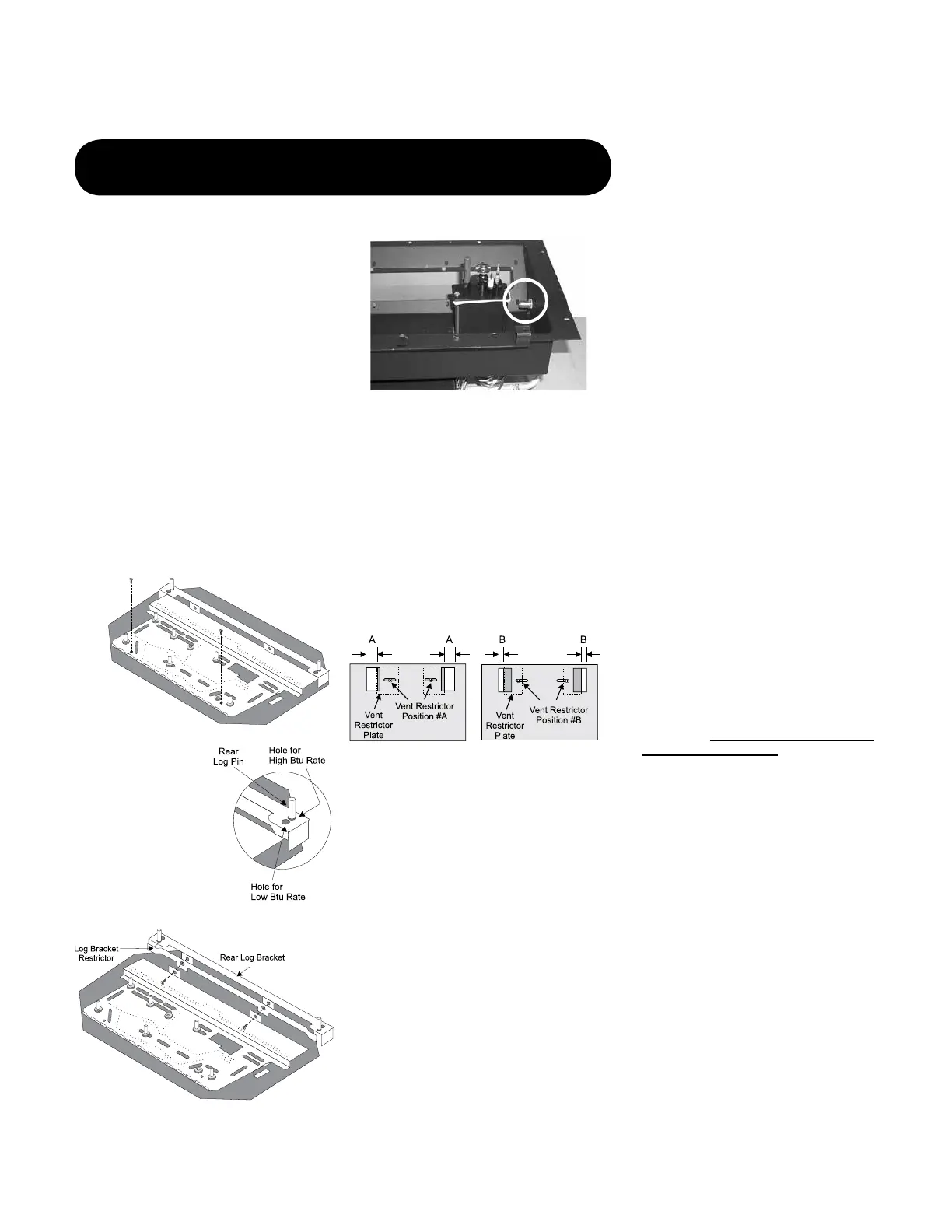

3. Remove burner. See diagram below.

Burner Orice

4. Unscrew the 2 Rear

Log Pins and move

to the front hole

position.

5. Remove Rear Log

Bracket and slide

the Log Bracket

Restrictor between

Position the Log Bracket Restrictor between

the Rear Log Bracket and the burner.

6. Remove burner orice with a 1/2" wrench

and discard.

The manifold pressure is controlled by a regulator

built into the gas control, and should be checked

at the pressure test point.

Note: To properly check gas pressure, both

inlet and manifold pressures should

be checked using the valve pressure

ports on the valve.

1. Make sure the valve is in the "OFF" position.

2. Loosen the "IN" and/or "OUT" pressure

tap(s), turning counterclockwise with a 1/8"

wide at screwdriver.

3. Attach manometer to "IN" and/or "OUT"

pressure tap(s) using a 5/16" ID hose.

4. Light the pilot and turn the valve to "ON"

position. Read manometer.

5. The pressure check should be carried out

with the unit burning and the setting should

be within the limits specied on the safety

label.

6. When nished reading manometer, turn

off the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8" at

screwdriver. Note: Screw should be snug,

but do not over tighten

7. Reinstall new burner orice (NG stamped

#37 or LP stamped #52. and tighten.

8. Reverse steps 3. and 2..

9. Adjust Vent restrictor setting: To set the

Vent restriction as indicated in the diagram,

simply loosen the screws and push the vent

restrictor plate to the correct position. Tighten

the screws.

Unit Btu/h Restrictor Opening

U39 38,000 A 1-3/4" (44mm)

30,000 B 1-1/4" (32mm)

Note: Use a

magnetic type

screwdriver if

possible.

the Rear Log Bracket and the burner, secure

with the 2 screws.

Vent Restrictor set-

ting at High Btu/h

Vent Restrictor set-

ting at Low Btu/h

10. Attach the label "This unit has been

converted to..." on top of the Serial # decal

over the higher Btu information.

11. Check for gas leaks.

12. Check inlet and outlet pressures.

13. Check operation of ame control. Check for

proper ame appearance and glow on logs.

Loading...

Loading...